Building ground brick paving equipment

A technology for laying bricks and floors, applied in construction, building structure and other directions, can solve problems such as physical harm to workers, affect the appearance of houses, easy to make mistakes, etc., and achieve the effects of complex structure, resource saving and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

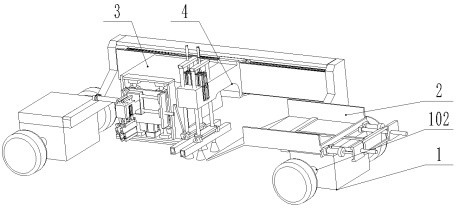

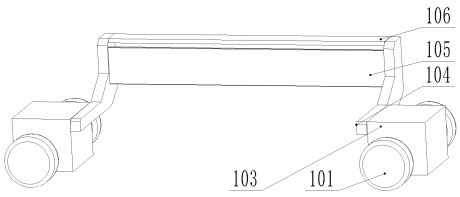

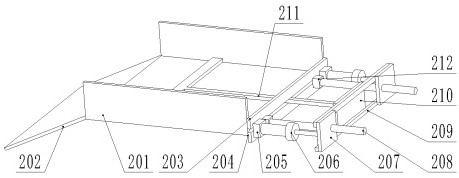

[0021] Example: figure 1 It is a schematic diagram of the overall structure of the present invention, including a mobile chassis module 1, a tile push-out module 2, a cement scraping module 3, and a tile tightening module 4. The mobile chassis module 1 includes a mobile chassis module bottom block 103, and a mobile chassis module center support 105; Module 2 includes the tile pushing module storage area 201; the cement scraping module 3 includes the large connecting block 301 behind the cement scraping module; the tile pressing module 4 includes the tile pressing module connecting splint 401, the tile pressing module connecting bridge 402; the mobile chassis module 1 The bottom block 103 of the mobile chassis module and the tile push-out module storage area 201 in the tile push-out module 2 are fixedly installed, and the central bracket 105 of the mobile chassis module in the mobile chassis module 1 is connected with the rear big connection block of the cement scraper module in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com