Slippage construction deviation rectifying device and slippage deviation rectifying method

A deviation-correcting device and slip technology, applied in the processing of building materials, construction, building maintenance, etc., can solve the problems of large time cost and economic cost, and achieve the effect of safe and reliable overall structure, simple structure, and easy production and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

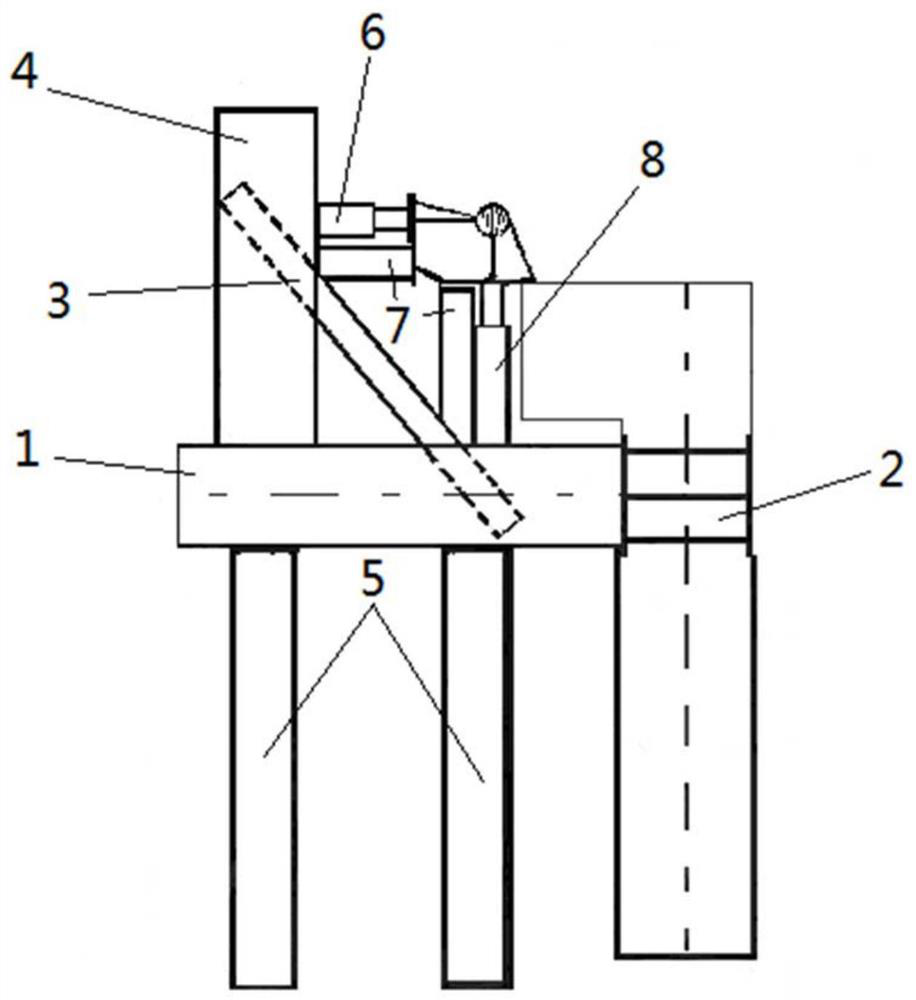

[0028] The invention provides a deviation correction device for sliding construction, which is used for offset bearings that deviate from the track. For the specific structure of the device, see figure 1 :

[0029] First install the rear embedded part 2 (20*400*400) on the load-bearing structure of the sliding track (generally a reinforced concrete load-bearing wall), and then weld one end of the main beam 1 of the entire device to the rear embedded part 2. Two round steel bars 5 (180*8) are welded under the main beam 1 as the main supporting points in the vertical direction of the main beam 1 to ensure its stability. A square tube 4 (300*16) is placed vertically above the beam as the horizontal reverse thrust point for slip correction. In order to ensure the integrity of the device and ensure its stress stability, a channel steel 3 (16a) is welded between the main beam 1 and the square tube 4 as a reinforcement. Two hydraulic reverse thrust jacks in the vertical direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com