Deicing wind power blade heating system detection device and method

A wind power blade and heating system technology, applied in wind power generation, wind turbine, wind turbine monitoring, etc., can solve the failure detection of the heating device inside the blade, the inability to comprehensively detect the blade surface temperature, and the hidden dangers of normal operation of deicing blades, etc. problems, to achieve the effect of saving manpower, easy to determine, and high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

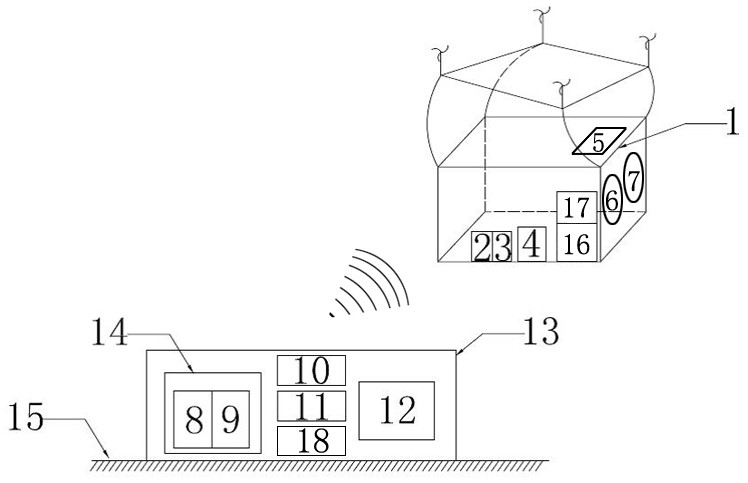

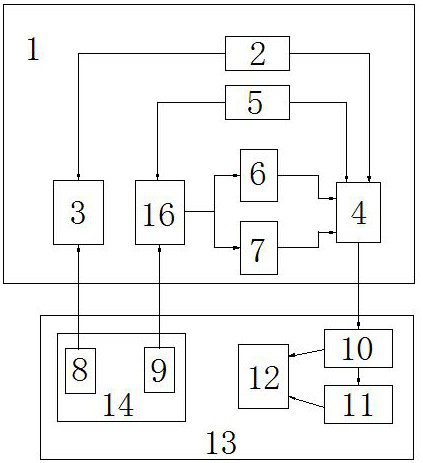

[0026] As shown in the figure, the detection device of the deicing wind power blade heating system of the present invention includes an unmanned aerial vehicle 1, a ground controller 14 for controlling the unmanned aerial vehicle and a ground central console 13 for processing data. There is an aircraft controller 3 for controlling the UAV according to the operation instructions of the ground controller and an aircraft position sensor 2 for detecting the altitude and position information of the UAV. The unmanned aerial vehicle 1 adopts the existing unmanned aerial vehicle technology, and the specific structure and control method will not be described in detail. The ground controller 14 and the ground central console 13 can be integrated to process and analyze the data collected by the unmanned aerial vehicle while manipulating the detection of the unman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com