Life buoy inflation detection device and method

A detection device and technology of a life buoy, which is applied to the container filling method, the container discharge method, the installation device of the container structure, etc., can solve the problem of inability to accurately judge whether the life buoy is full, the increase of the swing range of the pressure gauge value, and the inability to meet the factory requirements and other problems, to achieve the effect of shortening the inflation time, improving the control accuracy and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

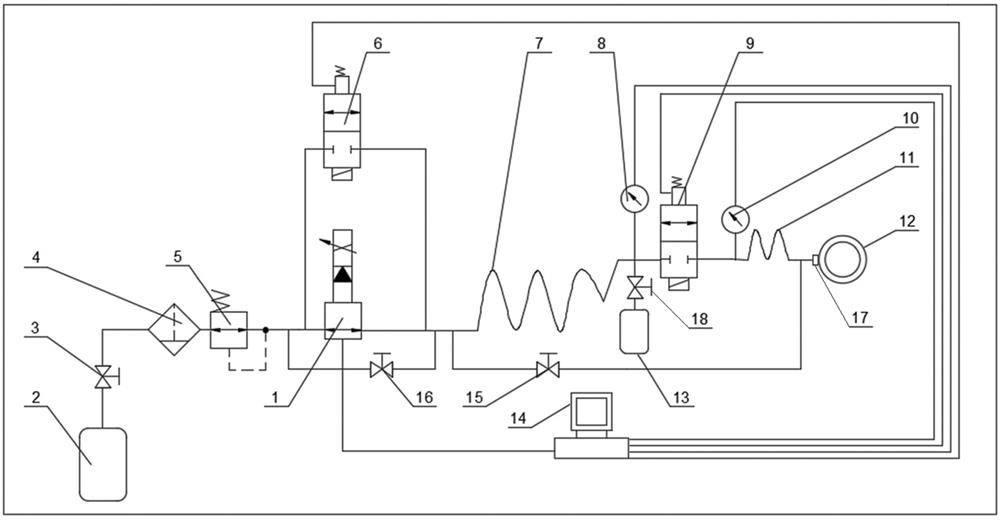

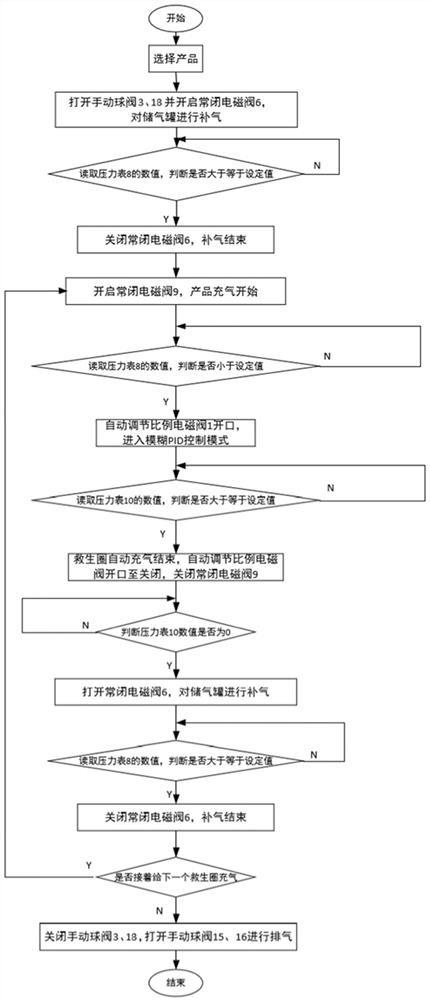

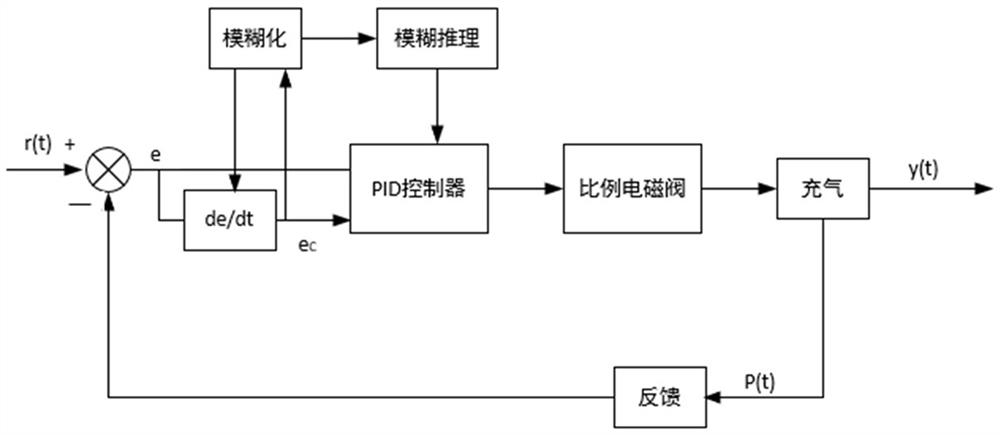

[0029] Such as figure 1 As shown, the present invention provides a lifebuoy inflation detection device, including an air source 2, a proportional solenoid valve 1, a first normally closed solenoid valve 6, a second normally closed solenoid valve 9, a first buffer air pipe 7, and a second buffer air pipe 11. Air storage tank 13, first pressure sensor 8, second pressure sensor 10, inflation nozzle 17 and industrial computer 14, the gas source 2 is connected to the intake end of the proportional electromagnetic valve 1 through the connecting air pipe, and the proportional electromagnetic valve The outlet end of the valve 1 is connected to the inlet end of the first buffer air pipe 7 through the connecting air pipe, the two ends of the proportional solenoid valve 1 are connected in parallel with the first normally closed electromagnetic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com