Chipless cutting device and method for steel tubes

A technology for cutting devices and steel pipes, applied in the direction of pipe shearing devices, shearing devices, maintenance and safety accessories, etc., can solve the problems of easy generation of dust, difficult radial feed pressure, and easy damage of limit pins by impact, etc., to achieve Improve production efficiency, ensure continuity, and ensure effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

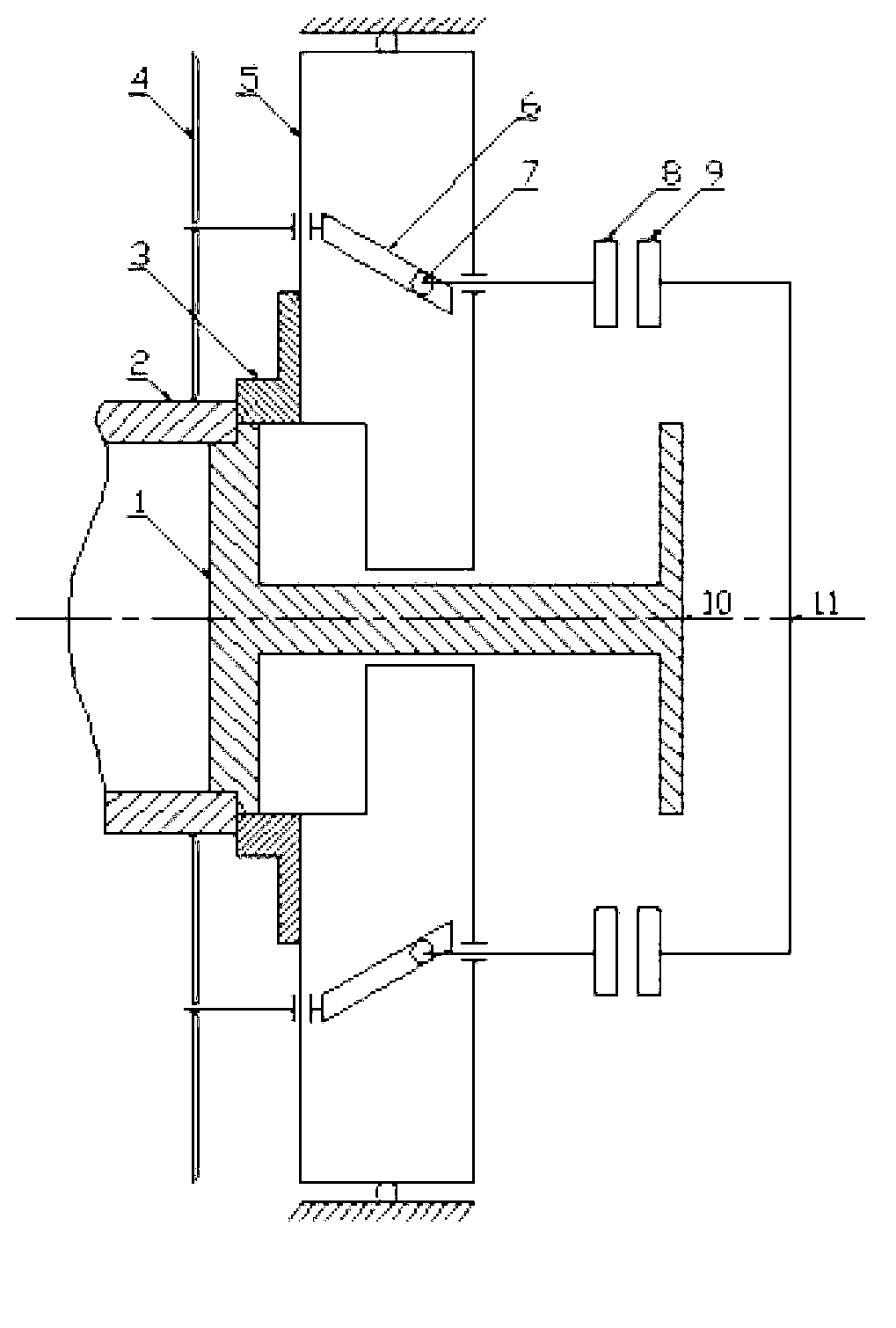

[0018] Referring to the accompanying drawings, a chipless cutting device for steel pipes includes a linear motor I 10 and a linear motor II 11, a thrust bearing seat I 8 and a thrust bearing seat II9, two inclined blocks 6, a hollow main shaft 5, a positioning plate 1, two Only the roller 7 and two blades 4, the inclined block is arranged inside the hollow main shaft, the blade is connected with the hollow main shaft, the inclined block is movably connected with the thrust bearing seat through the roller, the thrust bearing seat is connected with the linear motor, and the positioning plate is connected with the other A linear motor is connected, and the two blades, the two inclined blocks, the two rollers and the two sets of thrust bearing seats are arranged symmetrically along the center of the hollow main shaft.

[0019] The chipless cutting device for steel pipes also includes a discharge plate 3, which is arranged at one end of the hollow main shaft and is movably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com