Critical air treatment device

An air handling device and air heater technology, applied in air heaters, steam/steam condensers, lighting and heating equipment, etc., can solve the problems of high temperature and humidity, such as the production of corrosive liquid for electronic products, and reduce the floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

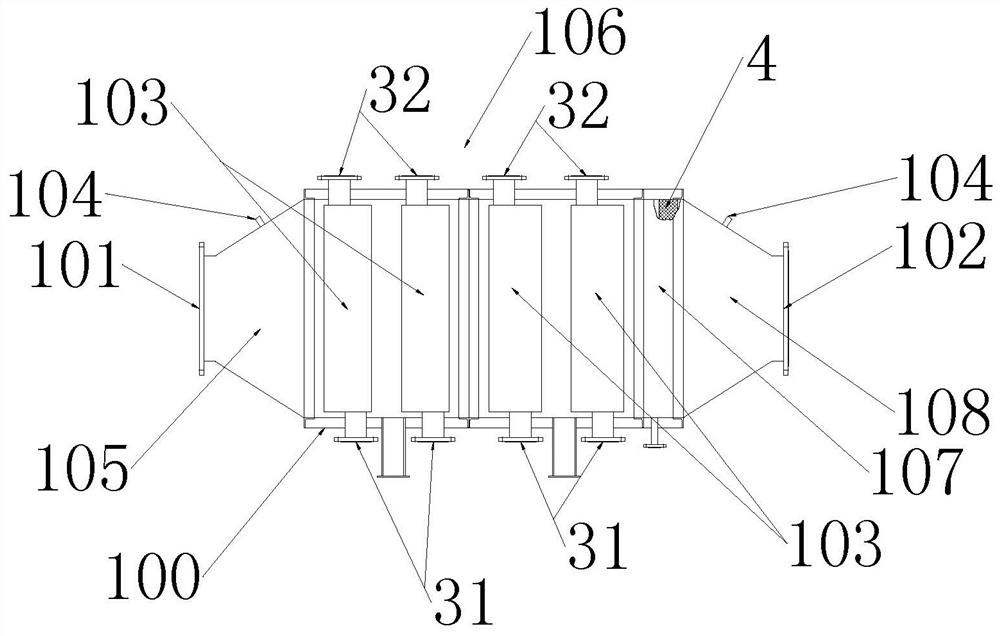

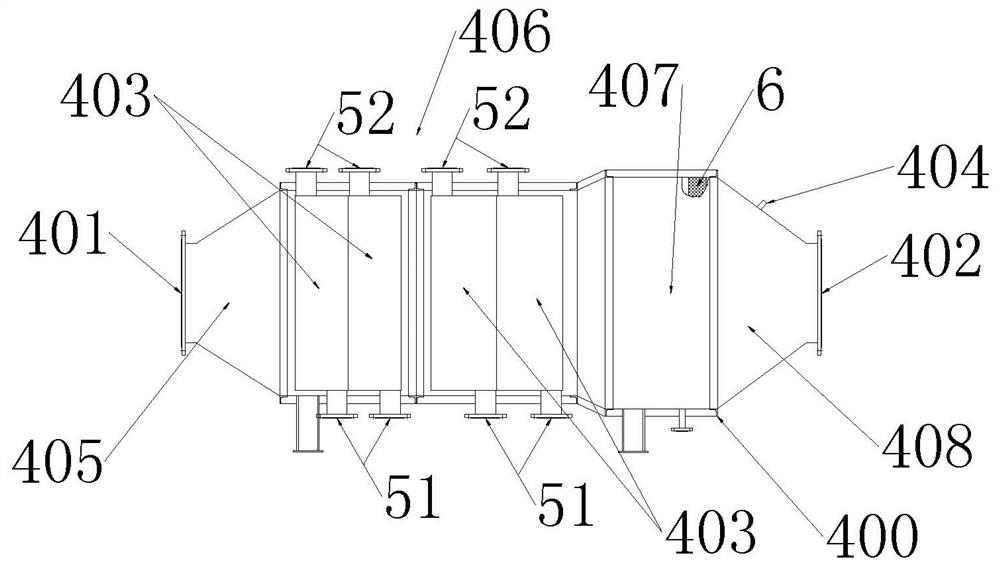

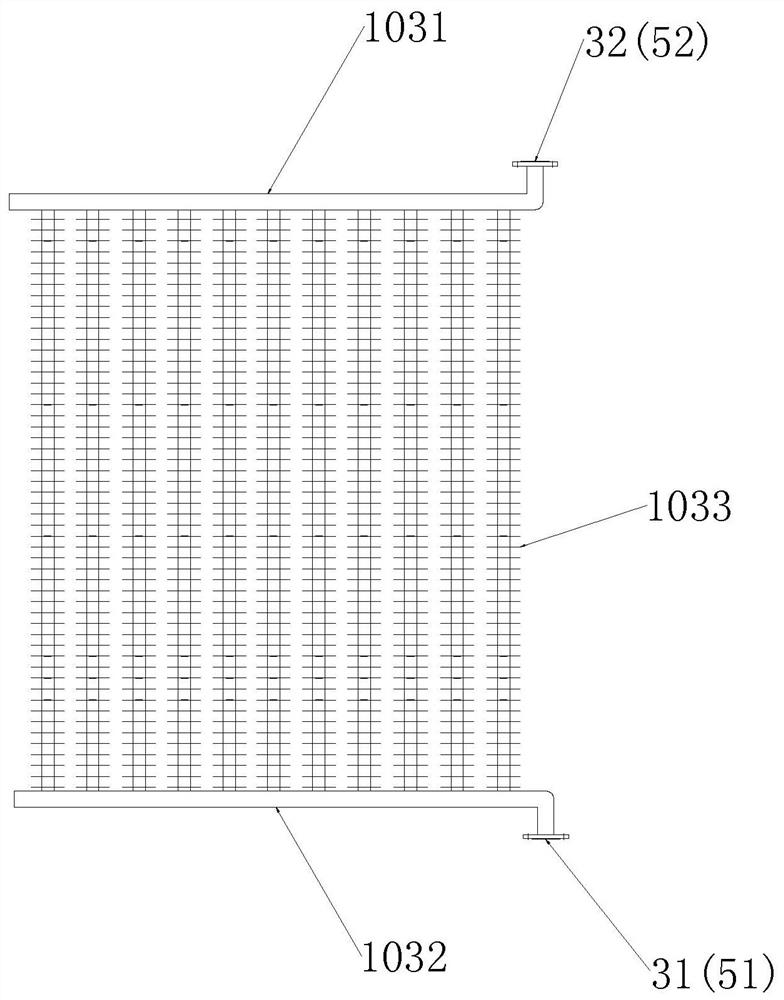

[0023] Such as figure 1 The shown critical air treatment device comprises a high-pressure blower 1, the air inlet of the high-pressure blower 1 is connected with a primary filter 2, and the air outlet of the high-pressure blower 1 is sequentially connected with a primary air cooler 3, a water separator-4, Secondary air cooler 5, water separator 2 6, air heater 7 and high efficiency filter 8, combined figure 2 , image 3 As shown, the primary air cooler 3 includes a primary air cooler housing 100, and the primary air cooler housing 100 is sequentially provided with an air inlet 101, a front cone 105, a heat exchange section 106, a water diversion Section one 107, rear cone one 108, air outlet one 102, the above-mentioned sections can be connected by welding to form a complete shell, heat exchange section one 106 is equipped with heat exchange tube box one 103, water diversion section one 107 is installed with Water separator one 4; similarly, secondary air cooler 5 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com