Virtual inspection system of digital factory

An inspection system and factory technology, applied in the field of virtual inspection system, can solve the problem of being unable to view real-time data of equipment at any time, and achieve the effects of adaptive adjustment, shortened retrieval time, and fast display speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following detailed description is given in conjunction with the accompanying drawings.

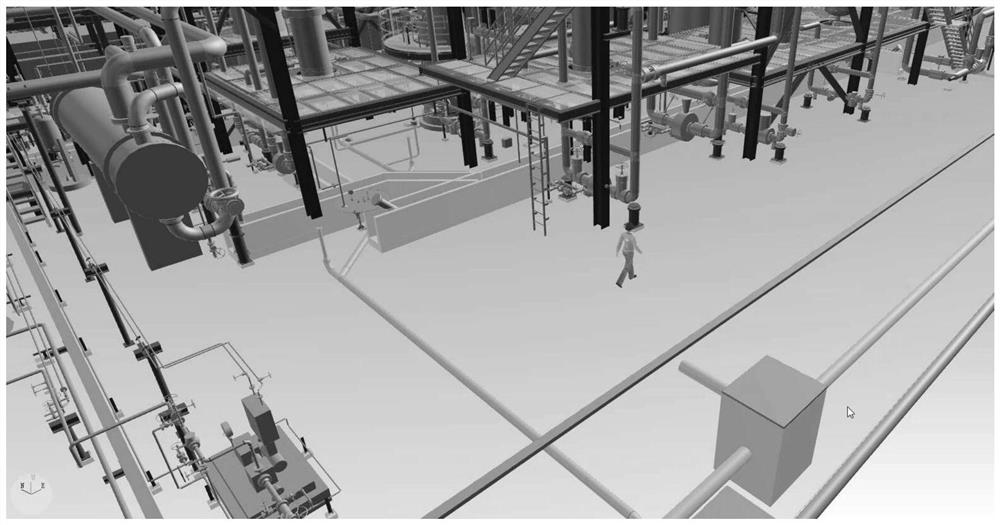

[0033] The invention provides a virtual inspection system of a digital factory, which can also be called a visual control system based on virtual inspection.

[0034] The picture frequency stream in the present invention refers to a video stream that can form a picture. Video streaming refers to the transmission of video data that, for example, can be processed as a steady and continuous stream over a network.

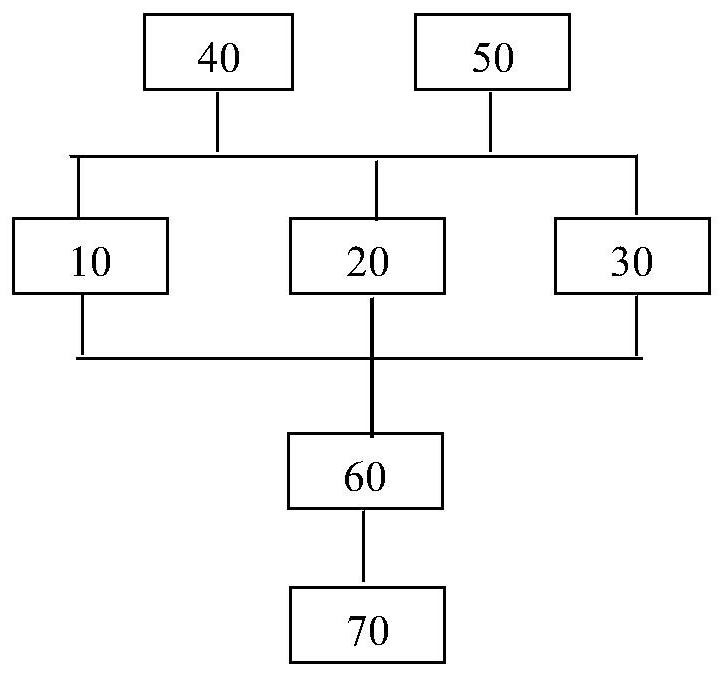

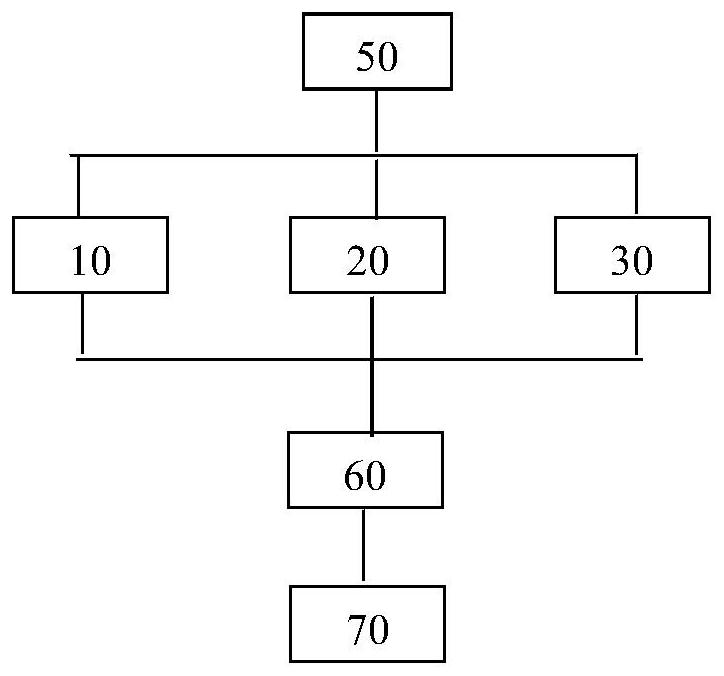

[0035] In the virtual inspection system of the present invention, the inspectors can conduct virtual inspections of the digital factory through the real perspective of roaming in the three-dimensional scene. The virtual three-dimensional scene of the digital factory of the present invention is consistent with the real scene of the physical factory in the building structure, equipment arrangement, and the connection relationship of the equipment. That is, the three-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com