Method for selecting thickness of bottom sealing concrete of steel cofferdam with reinforced shearing force

A technology of back-sealing concrete and steel cofferdams, which is applied in the direction of architecture, instruments, and geometric CAD, and can solve problems such as increasing the height of steel hanging box cofferdams, increasing construction difficulty, and violating the overall concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

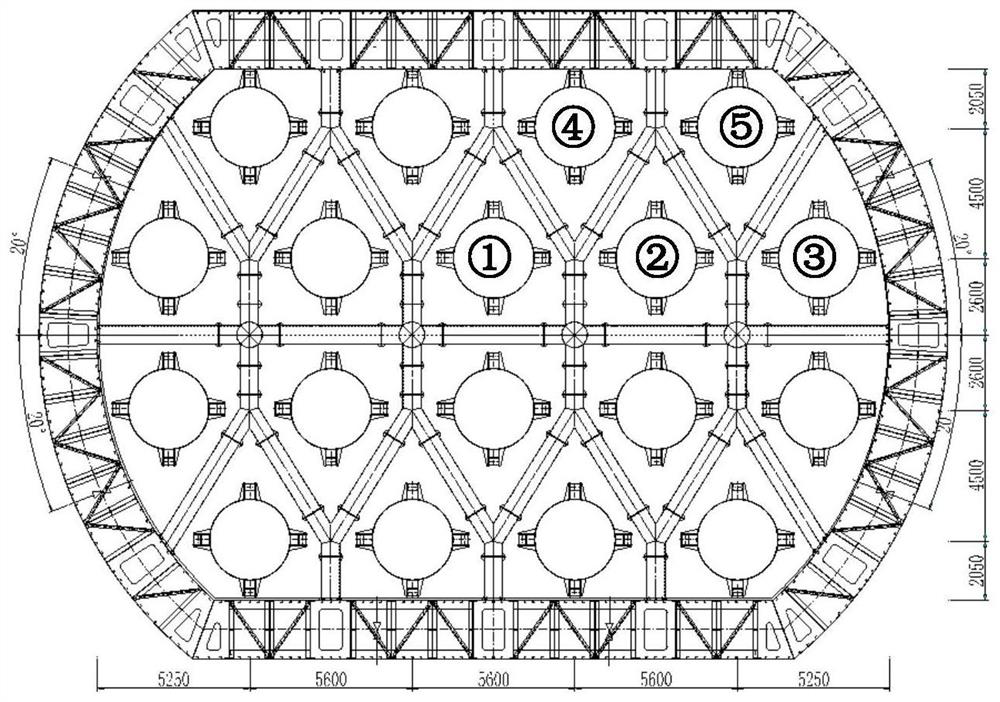

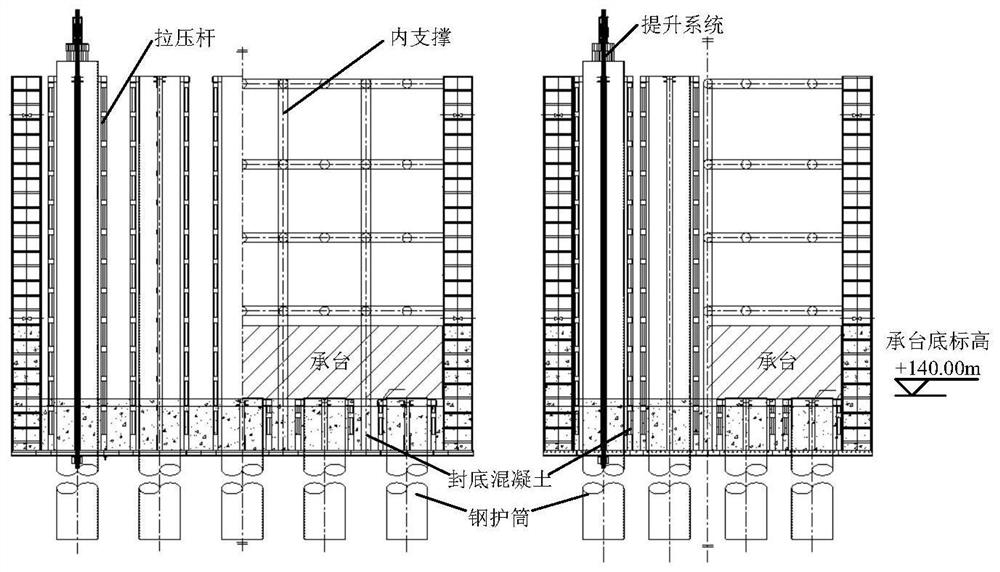

[0050] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0051] A method for selecting the thickness of the bottom-sealing concrete of a steel cofferdam with shear reinforcement is carried out according to the following steps:

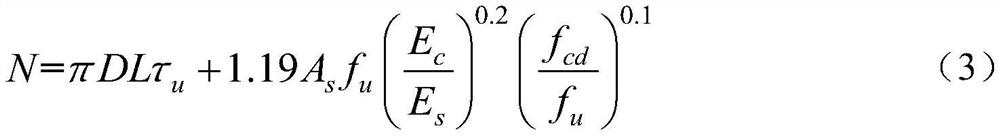

[0052] Step 1. Calculate the thickness L of the back cover concrete at the highest water level high ;

[0053] A number of said shear studs are respectively arranged on the outer wall of each said steel casing, and at least two annular shear zones are axially arranged on the upper part of the same said steel casing, and in said annular shear zones A number of said shear studs are horizontally fixed on the inner ring, said shear studs are aligned in the axial direction, the diameter of the shear studs is 22 mm, and the height is 90 mm;

[0054] The distance between two circumferentially adjacent shear studs in the same annular shear zone is not less than 3-4 times the diameter of the shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com