Electronic tag for preventing management and control equipment from flowing

An electronic label and equipment technology, which is applied to record carriers, instruments, and computer parts used in machines, can solve the problems that criminals are easy to forge, and it is difficult for prosecutors to inspect visually. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

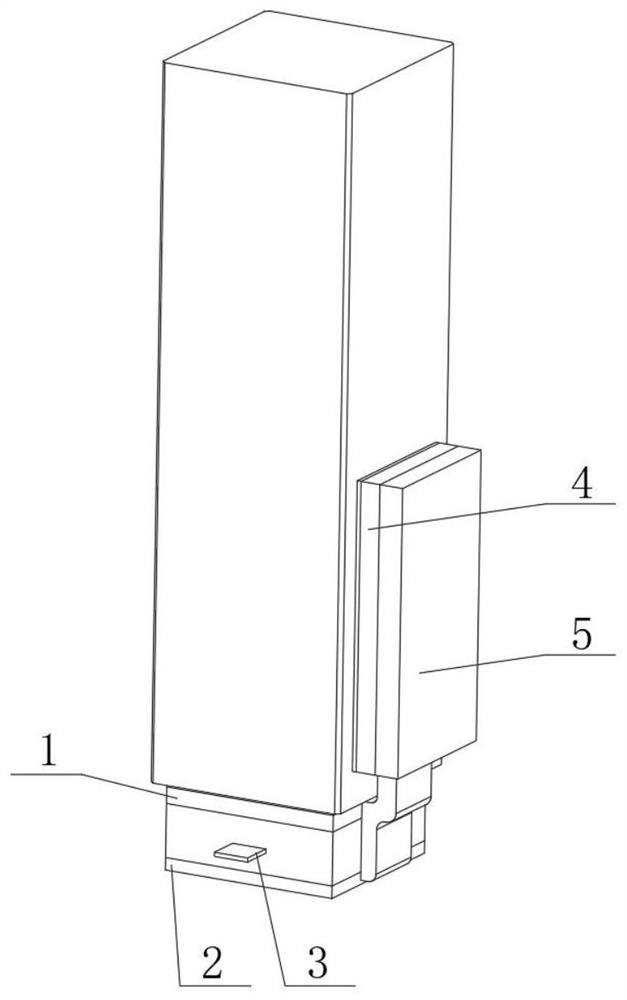

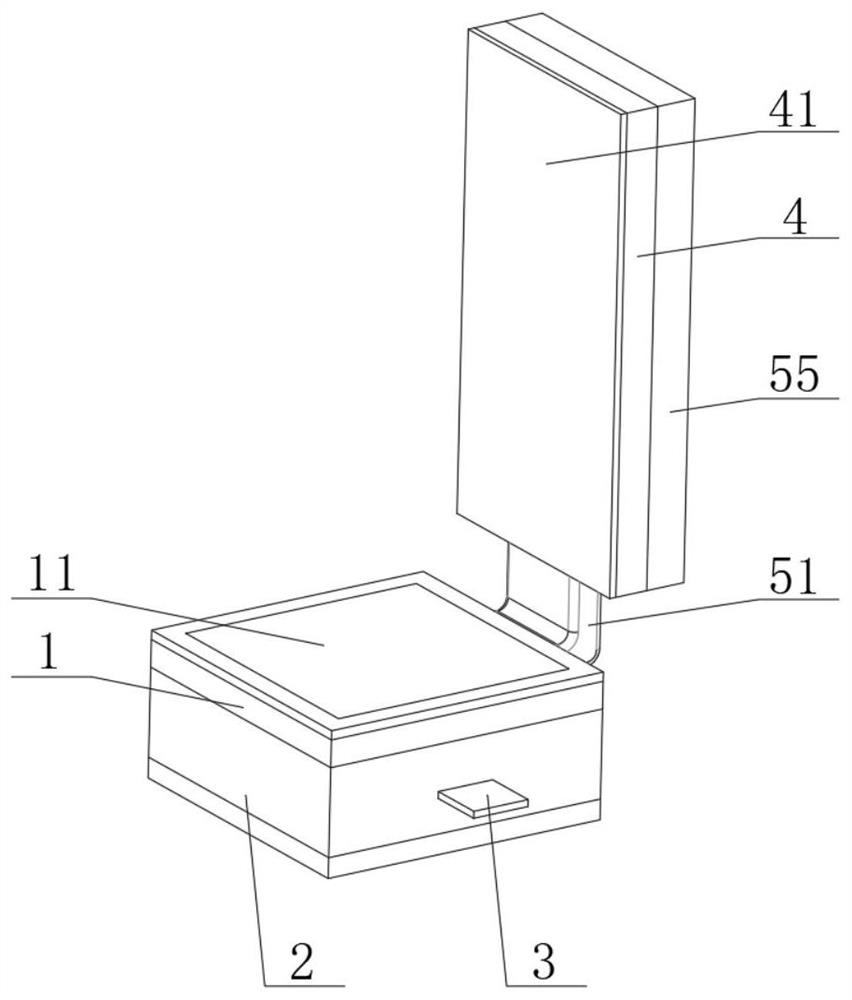

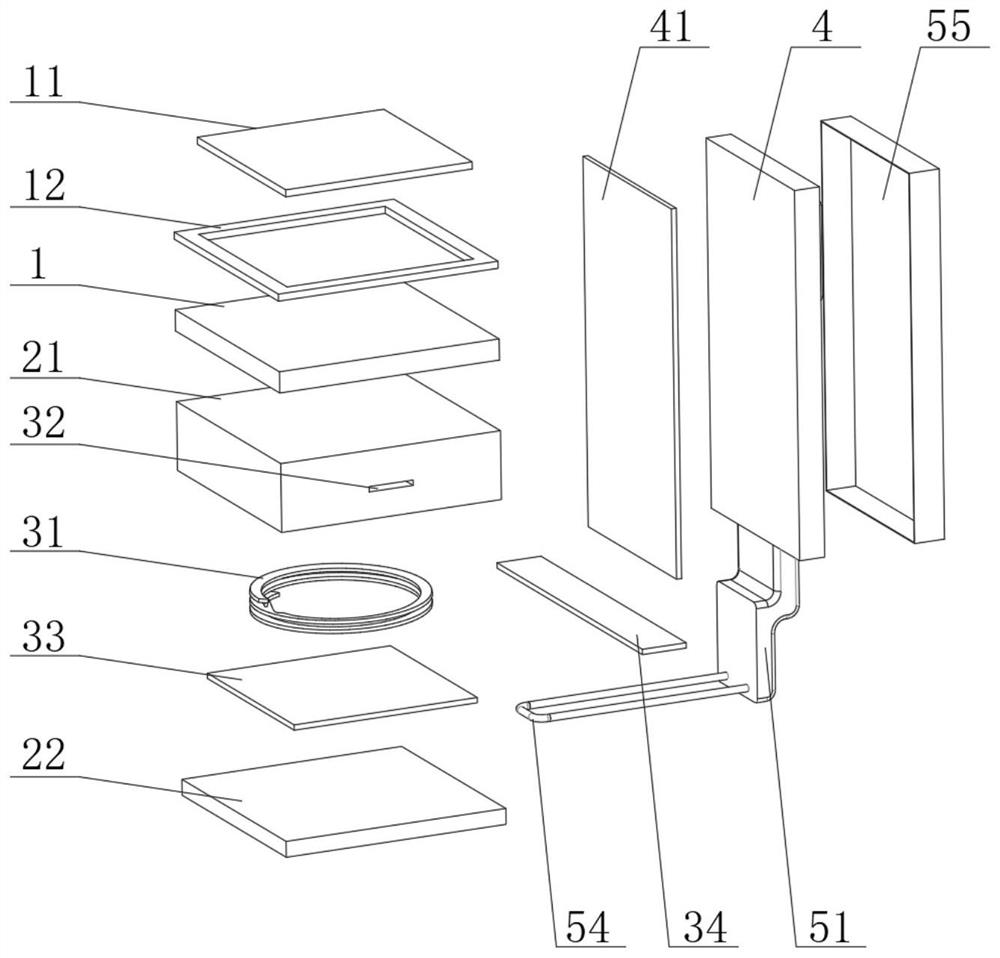

[0029] see Figure 1-3 , an electronic tag for preventing the flow of management and control equipment, comprising a bottom mounting substrate 1 and a side mounting substrate 4, the bottom of the bottom mounting substrate 1 is provided with a bottom vulnerable mechanism 2, and the bottom vulnerable mechanism 2 includes a return-shaped mounting seat 21 and a bottom Fragile strip 22, the bottom fragile strip 22 is fixedly connected to the bottom of the bottom installation substrate 1 through the return-shaped mounting seat 21, the top of the bottom installation substrate 1 is fixedly connected with the top strong viscose 11, and the outside of the top strong viscose 11 is provided with The protection ring 12 is fixedly connected to the top of the bottom mounting substrate 1 .

[0030] In this embodiment, during installation, the operator sticks the bottom installation substrate 1 to the bottom of the equipment support leg through the top strong glue 11, and the protective ring 1...

Embodiment 2

[0032] see Figure 1-3 , this embodiment is further optimized on the basis of Embodiment 1, specifically, the bottom energy storage mechanism 3 is provided inside the return-shaped mounting seat 21, and the bottom energy storage mechanism 3 includes a bottom push plate 33 and a plastic spring 31 , the plastic spring 31 is fixedly connected between the bottom push plate 33 and the inner cavity top of the return-shaped installation seat 21 .

[0033] Specifically, energy storage grooves 32 are opened on both sides of the circular mounting seat 21 , and the energy storage grooves 32 penetrate the circular mounting seat 21 .

[0034] Specifically, the interior of the energy storage tank 32 is slidably connected with an excitation draw bar 34 , and the excitation draw bar 34 is movably connected with the bottom push plate 33 .

[0035] In this embodiment, after the installation is completed, the operator pulls out the excitation drawer 34, and the plastic spring 31 releases the el...

Embodiment 3

[0037] see Figure 1-4 , the present embodiment is optimized as follows on the basis of example 1 or example 2, specifically, a detection mechanism 5 is provided on one side of the side mounting substrate 4, and the detection mechanism 5 includes a connecting belt 51, a solar energy supply plate 52, The detection lamp 53 and two thin wires 54, the side installation substrate 4 is fixedly connected to the bottom installation substrate 1 through the connecting belt 51, the solar energy supply board 52 and the detection lamp 53 are fixedly connected to one side of the side installation substrate 4, and the thin The middle part of the wire 54 runs through the connecting belt 51 and is fixedly connected between the circular mounting base 21 and the bottom fragile bar 22 , and the solar energy supply board 52 is electrically connected with the detection lamp 53 through the thin wire 54 .

[0038] Specifically, the side of the side mounting substrate 4 away from the solar energy supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com