Equipment distribution method in food processing production

A technology for equipment distribution and food processing, applied in instruments, manufacturing computing systems, data processing applications, etc. The effect of equipment utilization rate and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

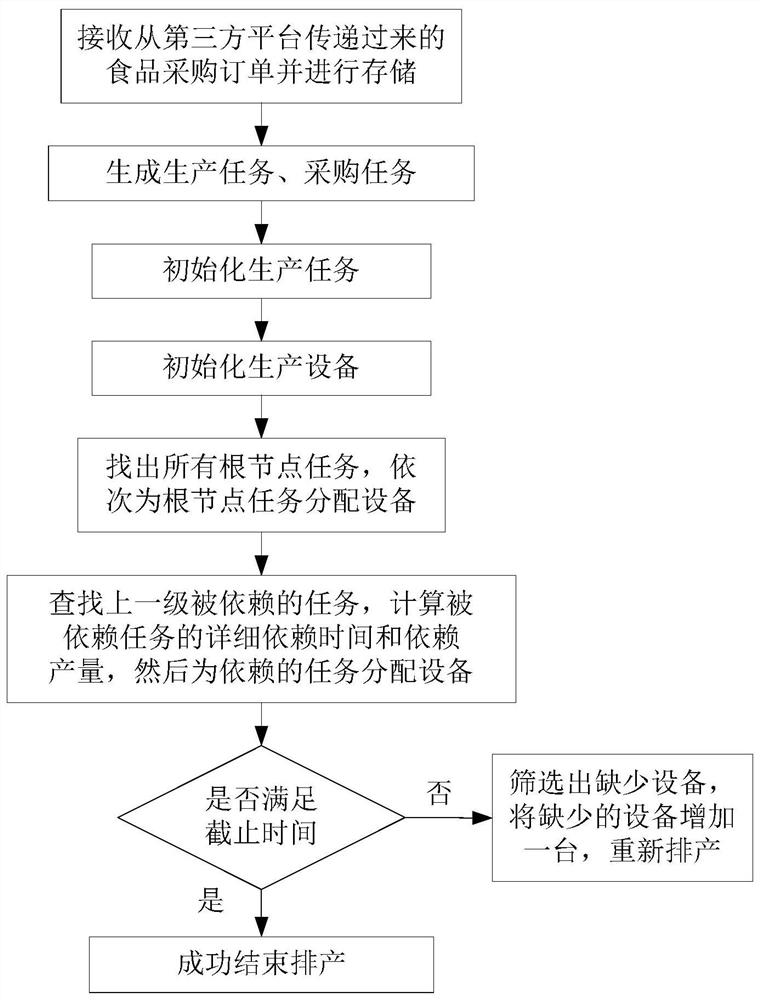

[0044] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0045] Such as figure 1 As shown, an equipment distribution method in a food processing production of the present invention comprises the following steps:

[0046] S1. Receive and store the food purchase order delivered from the third-party platform (e-commerce platform, ERP system, etc.); convert the order uploaded by the third-party platform into energy in the processing system according to the data correspondence method agreed with the third-party platform The recognized order data format;

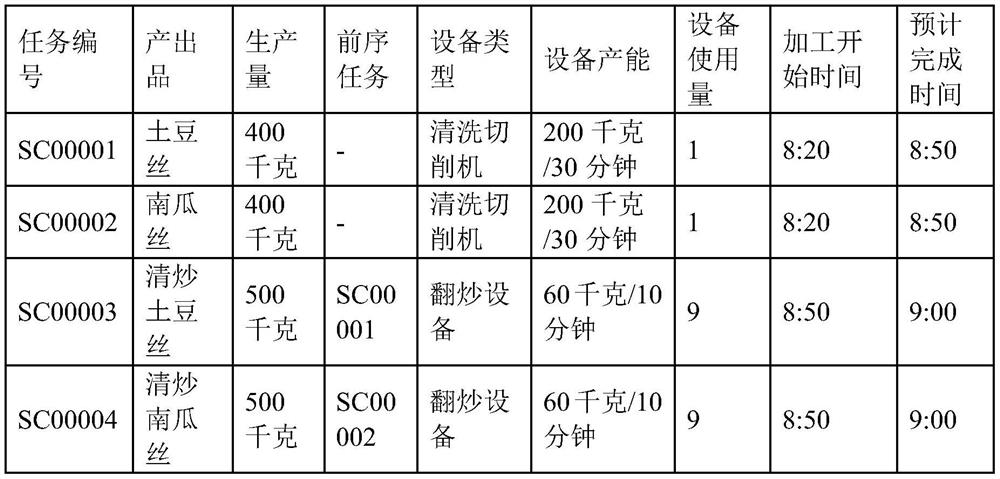

[0047] S2. According to the demand time of the goods in the order and the processing flow and raw materials of the goods, the production tasks are generated according to the processing flow (because the production tasks are generated step by step, there is an interdependence between the production tasks), and according to the current inventory and The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com