Graphite plate type heater

A graphite plate and heater technology, which is applied in the direction of ohmic resistance heating, heating element materials, electric heating devices, etc., can solve the problems of difficult processing, high cost, easy fracture of graphite plates, etc., and achieve simple processing, low processing cost, Solve the effect of insufficient internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

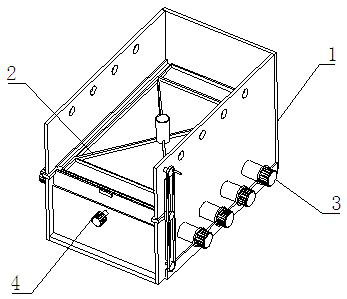

[0031] like Figure 1-6 As shown, the present invention provides a graphite plate heater, comprising a box body 1, a fixed power supply device 2 is fixedly installed on the upper and lower surfaces of the box body 1, a protective gas device 3 is arranged on the left and right sides of the box body 1, and the front surface of the box body 1 A sealing cover 4 is fixedly installed.

[0032] In this embodiment, the fixed energizing device 2 is used for the fixed support and energization of the graphite plate, the shielding gas device 3 is responsible for cooling and protecting the graphite plate after heating, and the sealing cover 4 is used for sealing the front end during heating.

[0033] like Figure 1-6 As shown, in this embodiment, preferably, the protective gas device 3 includes a gas upper port 31 and a gas lower port 32, the gas upper port 31 is set at the upper ends of the left and right sides of the box body 1, and the gas lower port 32 Opened at the lower ends of the...

Embodiment 2

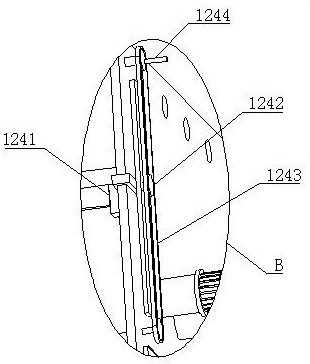

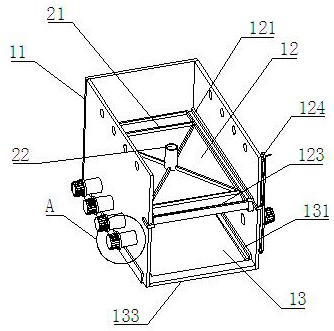

[0035] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the box body 1 includes a box side wall 11, and an upper graphite plate 12 is movably installed on the left and right surfaces of the box side wall 11, and the box side The lower end of the wall 11 is fixedly equipped with a lower graphite plate 13, and the left and right sides of the upper surface of the upper graphite plate 12 are fixedly equipped with an upper movable sealing strip 121, and the left and right sides of the lower surface of the upper graphite plate 12 are fixedly installed with a lower movable sealing strip 122. The upper front sealing plate 123 is fixedly installed on the front surface of 12, and the left and right sides of the front end of the upper graphite plate 12 are fixedly equipped with adjustment devices 124. The right side of the fixed frame 1241 is movably connected with a moving wheel 1242, the surface of the moving whee...

Embodiment 3

[0037] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the fixed power supply device 2 includes an upper dragon skeleton 21 and a lower dragon skeleton 23, and the upper dragon skeleton 21 is fixedly installed on the upper graphite plate 12 On the surface, the lower dragon frame 23 is fixedly installed on the lower surface of the lower graphite plate 13, the center position of the upper surface of the upper dragon frame 21 is fixedly installed with a screw-type terminal 22, and the center position of the lower surface of the lower dragon frame 23 is fixedly installed with a fixed terminal 24 , the upper dragon frame 21 is fixed on the upper surface of the upper graphite plate 12, which can play an auxiliary supporting role for the entire upper graphite plate 12 and increase the strength of the upper graphite plate 12, and the lower dragon frame 23 plays the same role on the lower graphite plate 13, The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com