Graphene heating plate with packaging structure

A technology of packaging structure and heating plate, which is applied to heating elements, ohmic resistance heating, heating element materials, etc., to achieve the effects of simple structure, convenient processing and packaging, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

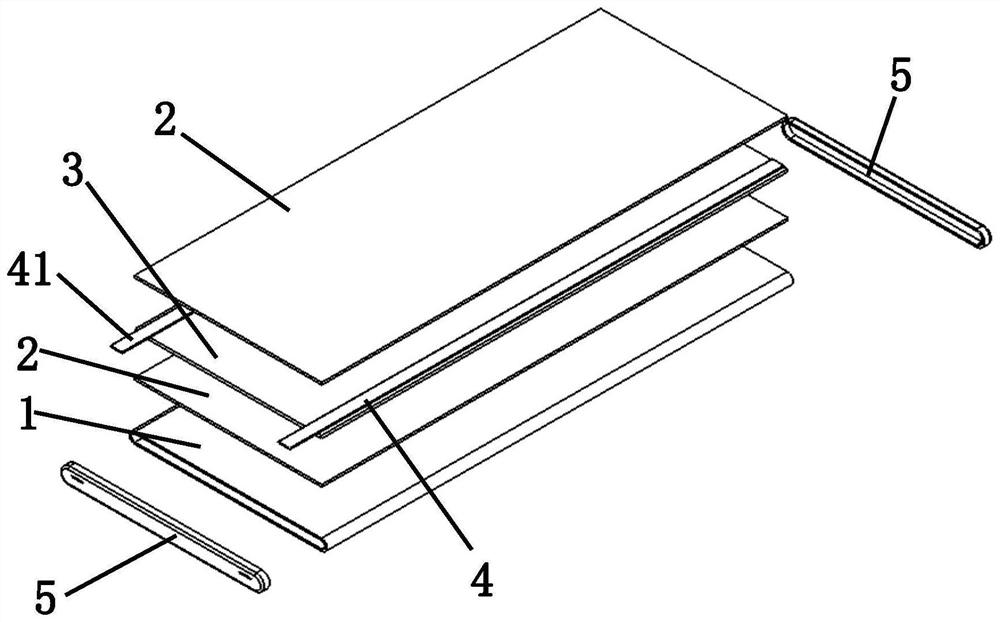

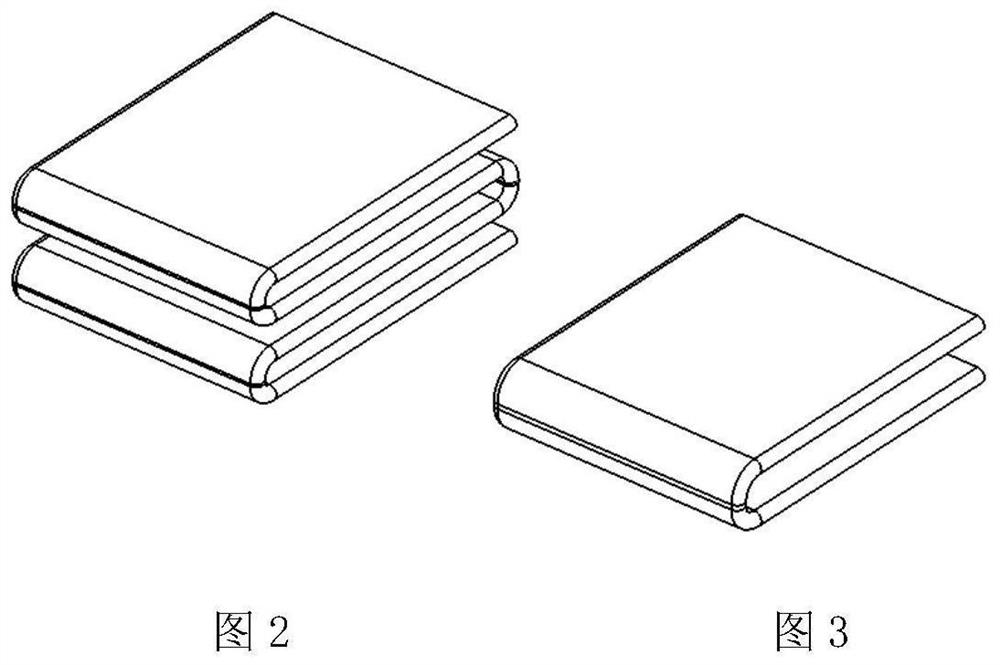

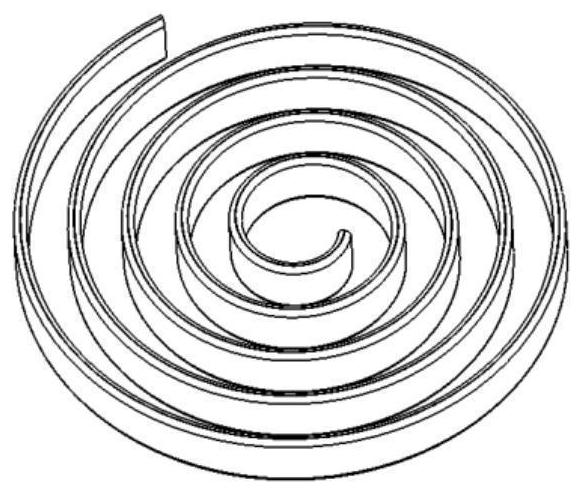

[0032] A graphene heating plate with encapsulation structure, such as figure 1 As shown, it includes a graphene heating film, an insulating layer 2, a metal casing 1 and an end cap 5. Wherein, the graphene heating film comprises the graphene diaphragm 3 of monolayer or multilayer composite structure and two electrodes 4 fixedly arranged along the edge of graphene diaphragm 3, and electrode 4 can be straight bar, L-shaped bar etc., and each electrode One of the ends of 4 forms the lead-out end 41 of the electrode at the wide side of the graphene membrane 3 . The insulating layer 2 is a mica plate or PI film or other insulating materials with good flexibility and thermal conductivity, and the insulating layer 2 is fixedly covered on the upper and lower surfaces of the graphene heating film to form the heating plate body. The cross section of the metal shell 1 is an oblate ring structure. The heating plate body is sealed and fixed in the inner cavity of the metal shell 1 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com