Preparation method of fermented Pu'er tea, capable of reducing tea residue rate

A technology of cooked Pu'er tea and a production method, which is applied in the directions of tea, tea spice, tea treatment before extraction, etc., can solve the problem of poor quality of Pu'er cooked tea, inability to effectively retain the fruit aroma and nutritional components of green citrus, and inability to reduce the rate of broken residues and other problems to achieve the effect of improving health care function, taste and aroma, reducing temperature and improving appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

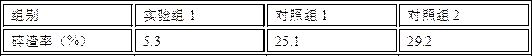

[0041] Embodiment 1: A method for making Pu-erh ripe tea with reduced tea residue rate, characterized in that it includes the following steps: Step 1): Picking; Step 2): Greening; Step 3): Cooling; Step 4): Twisting kneading; step 5): primary fermentation; step 6): secondary fermentation; step 7): drying; step 8): packaging and sterilizing; wherein, before the secondary fermentation process, the fermented green orange fruit vinegar is sprayed into the tea leaves; The drying in step 5) adopts negative pressure far-infrared drying.

[0042] By spraying fruit vinegar rich in vitamins and other nutrients and fruity aroma on the surface of tea leaves for fermenting, it is beneficial to retain the nutrients and aroma in the fruit, and is conducive to improving the health care function and taste aroma of Pu'er ripe tea; Two different degrees of fermentation are beneficial to control the fermentation effect, gradually ripen the tea leaves, and improve the fermentation effect; before t...

Embodiment 2

[0073] Embodiment 2: A method for making Pu-erh cooked tea with reduced tea residue rate, characterized in that it includes the following steps: step 1): picking; step 2): finishing; step 3): cooling; step 4): twisting kneading; step 5): primary fermentation; step 6): secondary fermentation; step 7): drying; step 8): packaging and sterilizing; wherein, before the secondary fermentation process, the fermented green orange fruit vinegar is sprayed into the tea leaves; The drying in step 5) adopts negative pressure far-infrared drying.

[0074] By spraying fruit vinegar rich in vitamins and other nutrients and fruity aroma on the surface of tea leaves for fermenting, it is beneficial to retain the nutrients and aroma in the fruit, and is conducive to improving the health care function and taste aroma of Pu'er ripe tea; Two different degrees of fermentation are beneficial to control the fermentation effect, gradually ripen the tea leaves, and improve the fermentation effect; befor...

Embodiment 3

[0091] Embodiment 3: A method for producing ripe Pu-erh tea with reduced tea residue rate, characterized in that it includes the following steps: Step 1): Picking; Step 2): Greening; Step 3): Cooling; Step 4): Twisting kneading; step 5): primary fermentation; step 6): secondary fermentation; step 7): drying; step 8): packaging and sterilizing; wherein, before the secondary fermentation process, the fermented green orange fruit vinegar is sprayed into the tea leaves; The drying in step 5) adopts negative pressure far-infrared drying.

[0092] By spraying fruit vinegar rich in vitamins and other nutrients and fruity aroma on the surface of tea leaves for fermenting, it is beneficial to retain the nutrients and aroma in the fruit, and is conducive to improving the health care function and taste aroma of Pu'er ripe tea; Two different degrees of fermentation are beneficial to control the fermentation effect, gradually ripen the tea leaves, and improve the fermentation effect; befor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com