Manufacturing equipment of pharmaceutic adjuvants

A technology for manufacturing equipment and pharmaceutical excipients, which is applied in the field of manufacturing equipment for pharmaceutical excipients, can solve problems such as freezing point depression, high maintenance costs, uneven adhesion to tower walls, etc., and achieve fast homogenization speed, high safety, and distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

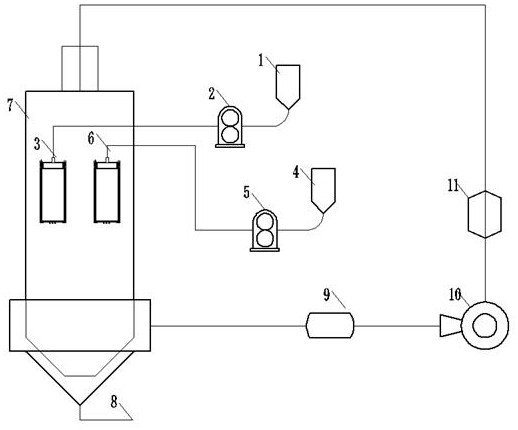

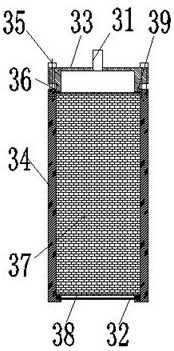

[0020] A manufacturing equipment for pharmaceutical excipients, mainly used to prepare pharmaceutical excipients stearic acid and cetostearyl alcohol; including a raw material tank, a delivery pump, a cooling tower 7, a separator 11, a fan 10 and a cooler 9; the The air outlet at the top of the cooling tower 7 is connected to the blower fan 10 through the separator 11, and the fan 10 is connected to the lower air inlet of the cooling tower 7 through the cooler 9 to form an air circulation; the bottom of the cooling tower is provided with a discharge port 8; A nozzle is installed inside the tower 7 through a pipeline, and the nozzle is connected to the raw material tank through a delivery pump.

[0021] The raw material in the raw material tank is transported to the cooling tower 7 through the nozzle, dispersed into liquid droplets and falls down; , forming a cycle. The falling raw material droplets and the cold air countercurrently contact and immediately solidify into solid ...

Embodiment 2

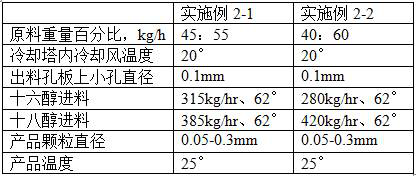

[0024] The equipment described in Example 1 was used to prepare small particles of cetostearyl alcohol as a pharmaceutical adjuvant: as shown in Table 1 below:

[0025] Table 1

[0026]

Embodiment 3

[0028] Adopt the equipment described in embodiment 1 to prepare stearic acid granules: specifically as shown in table 1 below:

[0029] Table 2

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com