Material intelligent screening system

An intelligent analysis and screening technology, which is applied in the fields of filtration, solid separation, and material analysis, can solve the problems of poor screening effect, low degree of intelligence, poor adaptability to working conditions, etc., and achieve good screening effect and intelligent The effect of high degree and strong adaptability to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

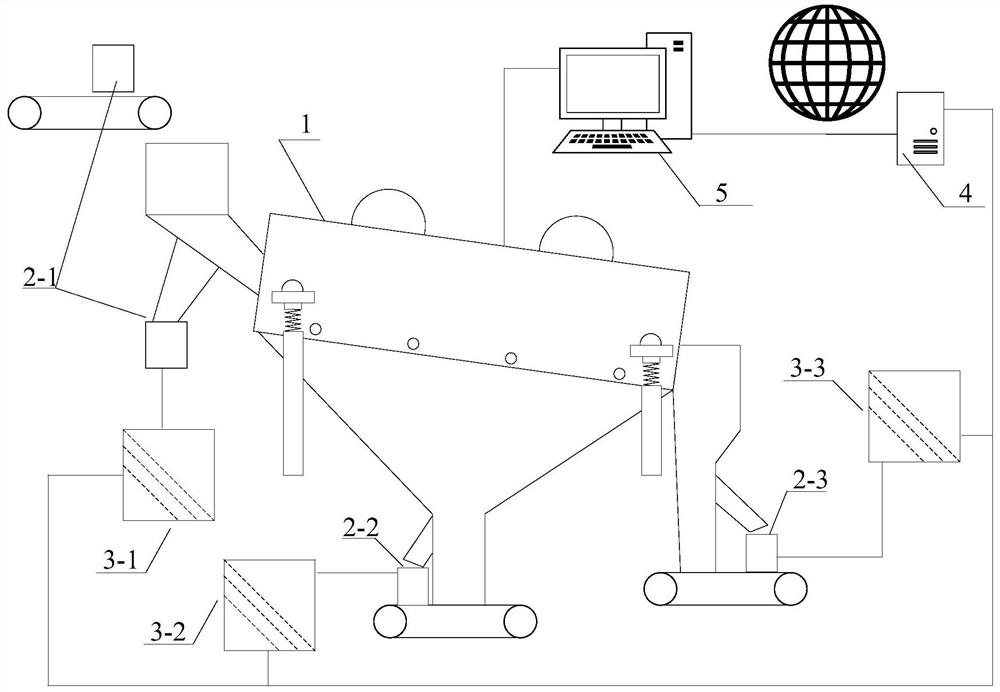

[0015] Such as figure 1 As shown, the present invention provides a material intelligent screening system including a screening machine 1, a feed automatic taking system 2-1, a screen, automatic taking system 2-2, and a sieve automatic tether 2-3 , Incubation particle size and weight intelligent analysis system 3-1, sieve particle size and weight intelligent analysis system 3-2, sieved particle size and weight intelligent analysis system 3-3, screening effect online intelligent analysis system 4, intelligent dynamics Regulatory system 5.

[0016] The feed automatic tapping system 2-1 is disposed on the feed chute or belt, the sieve, automatic taking system 2-2, is disposed on a sieve, or a belt, the sieve property. System 2-3 is disposed on the sieve lower slot or belt.

[0017] The injection particle size and weight intelligent analysis system 3-1, the particle size and weight intelligent analysis system 3-2, the mean granularity and weight intelligent analysis system 3-3 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com