Push type steel ball polishing device

A push type, steel ball technology, applied in the direction of grinding/polishing safety device, grinding feed movement, grinding workpiece support, etc., can solve problems such as difficult to handle particles, and achieve the effect of high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

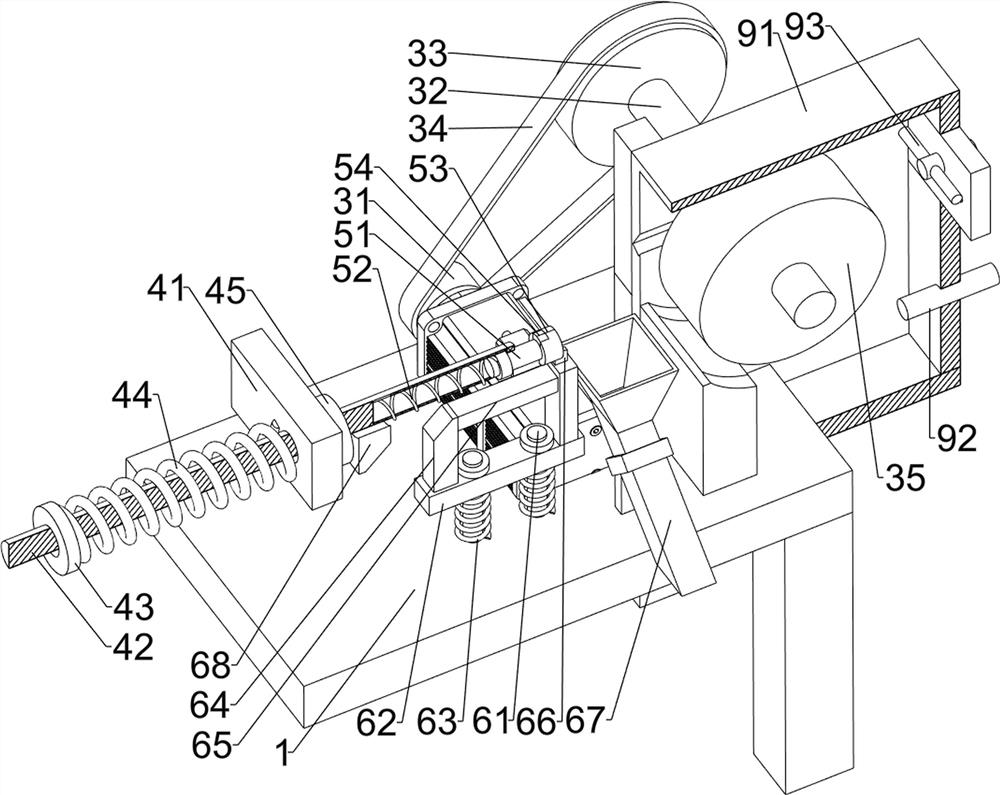

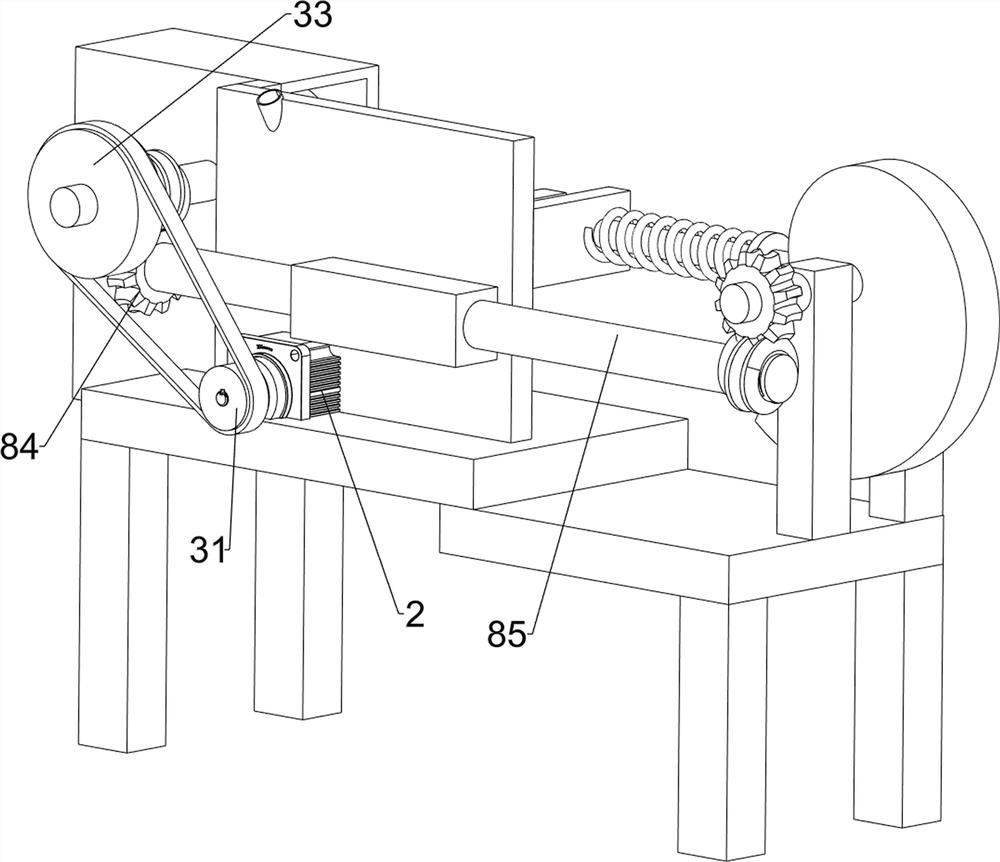

[0027] A push-type steel ball grinding device, such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, it includes a worktable 1, a motor 2, a grinding mechanism 3, a limit mechanism 4 and a stabilizing mechanism 5, a motor 2 is installed in the middle of the top rear side of the workbench 1, and a grinding mechanism 3 is arranged between the motor 2 and the workbench 1 , The top left side of the workbench 1 is provided with a limit mechanism 4, and the right side of the limit mechanism 4 is provided with a stabilizing mechanism 5.

[0028] The grinding mechanism 3 includes a first transmission wheel 31, a first rotating shaft 32, a second transmission wheel 33, a belt 34 and a polishing wheel 35. The rear part of the output shaft of the motor 2 is connected with the first transmission wheel 31, and the top right rear of the workbench 1 The side rotation type is provided with a first rotating shaft 32, the rear of the first rotating shaft 32 is connected with a sec...

Embodiment 2

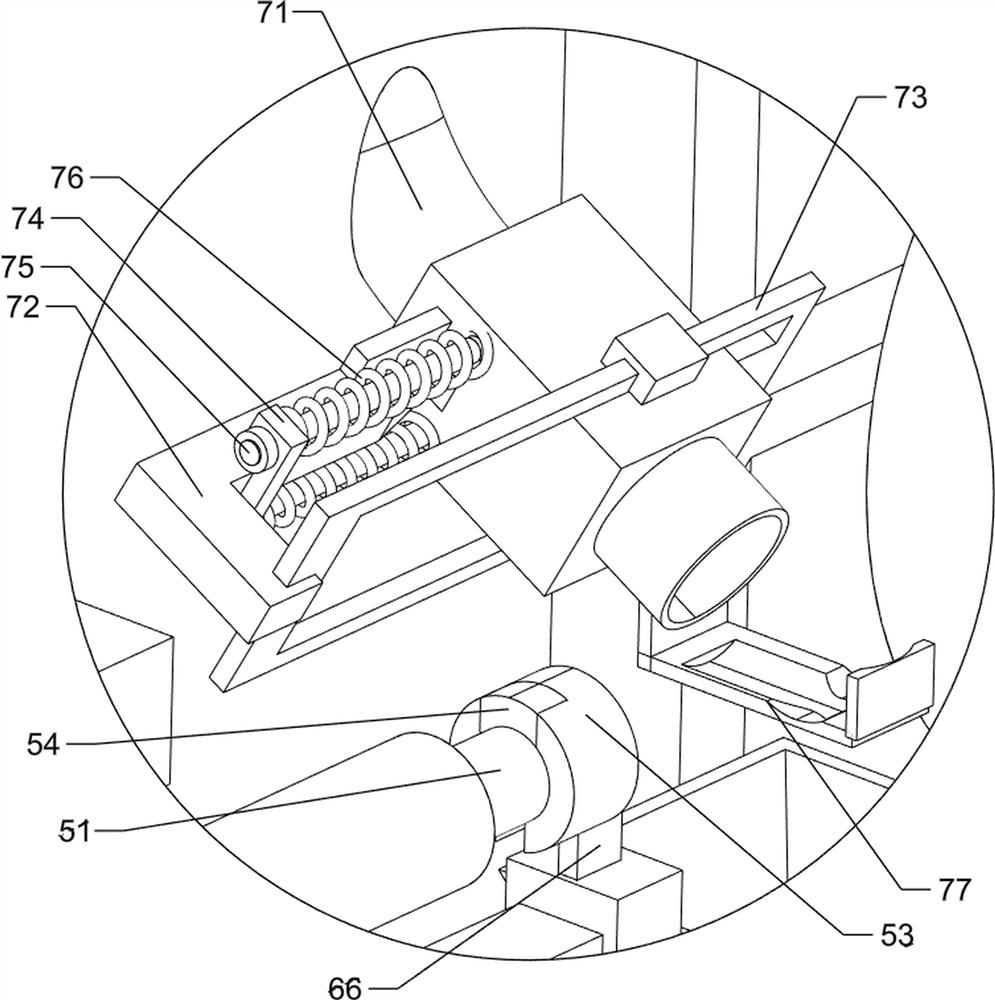

[0033] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, it also includes a blanking mechanism 6, and the blanking mechanism 6 includes a first guide rod 61, a first connecting block 62, a third spring 63, a first wedge block 64, a first stop block 65, a clamping block 66, The collection groove 67 and the second wedge block 68, the first guide rod 61 is symmetrically connected in the middle of the front side of the top of the workbench 1, and the first guide rod 61 is slidably provided with the first connecting block 62, and the first connecting block 62 and There are third springs 63 symmetrically connected between the worktables 1. The third springs 63 are respectively set on the first guide rods 61. The first wedge-shaped block 64 is connected to the left side of the top of the first connecting block 62. The top of the first connecting block 62 The right side is connected with a block 66, and the block 66 cooperates with the chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com