Gluing machine applied to production and processing of hollow glass

A technology of glue machine and glass, applied in the field of glue machine, can solve the problems of increasing the cleaning work of on-site operators, collecting glue liquid, unfavorable for the production and processing of insulating glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

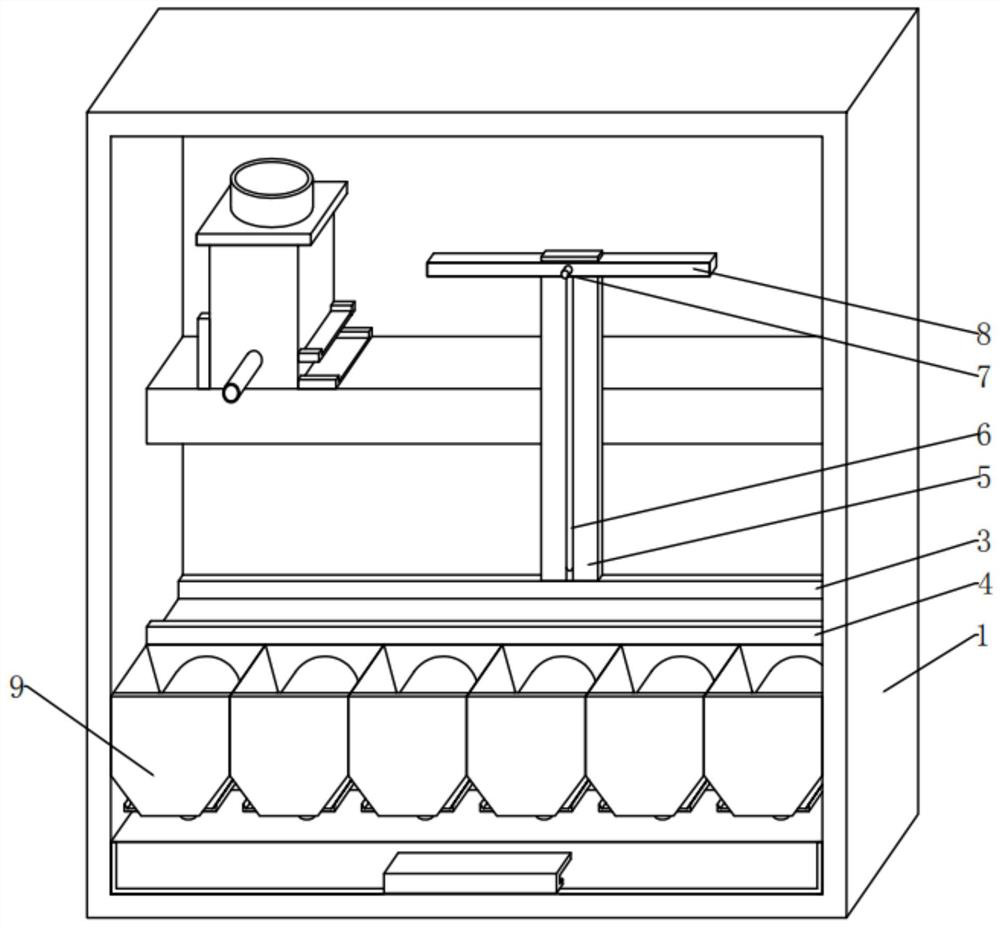

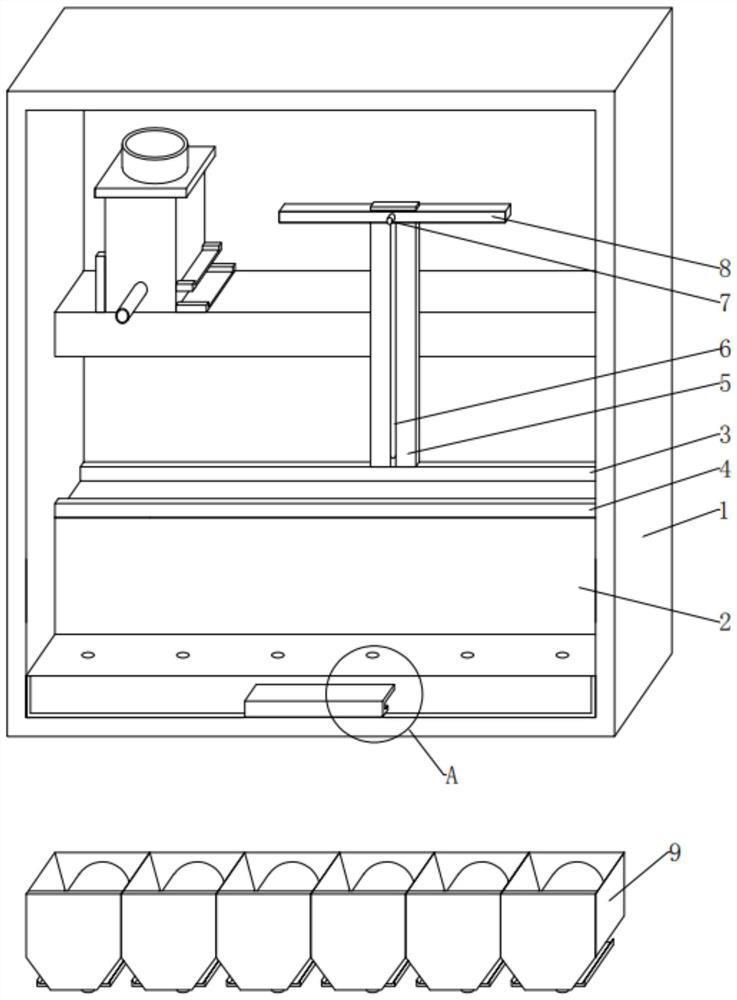

[0048] see Figure 1-3 , in an embodiment of the present invention, a gluing machine applied to the production and processing of insulating glass, including:

[0049] The main body of the glue machine 1 is fixedly installed with an operation table 2 at the bottom rear part between the left and right inner walls of the glue machine body 1, and the front and rear ends of the top outer surface of the operation table 2 are respectively fixedly installed with a fixed plate 3 and a movable Plate 4, the top position of moving plate 4 is left and right horizontal direction slides and is installed with fixed bar 5, and the front side middle end position of fixed bar 5 is provided with vertical chute 6 vertically up and down, and the top position of vertical chute 6 is fixed. A slide bar 8 is installed, and a fixed handle 7 is fixedly installed in the center of the front outer surface of the slide bar 8;

[0050] Glue-collecting assembly 9, the outer surface of the front side of the op...

Embodiment 2

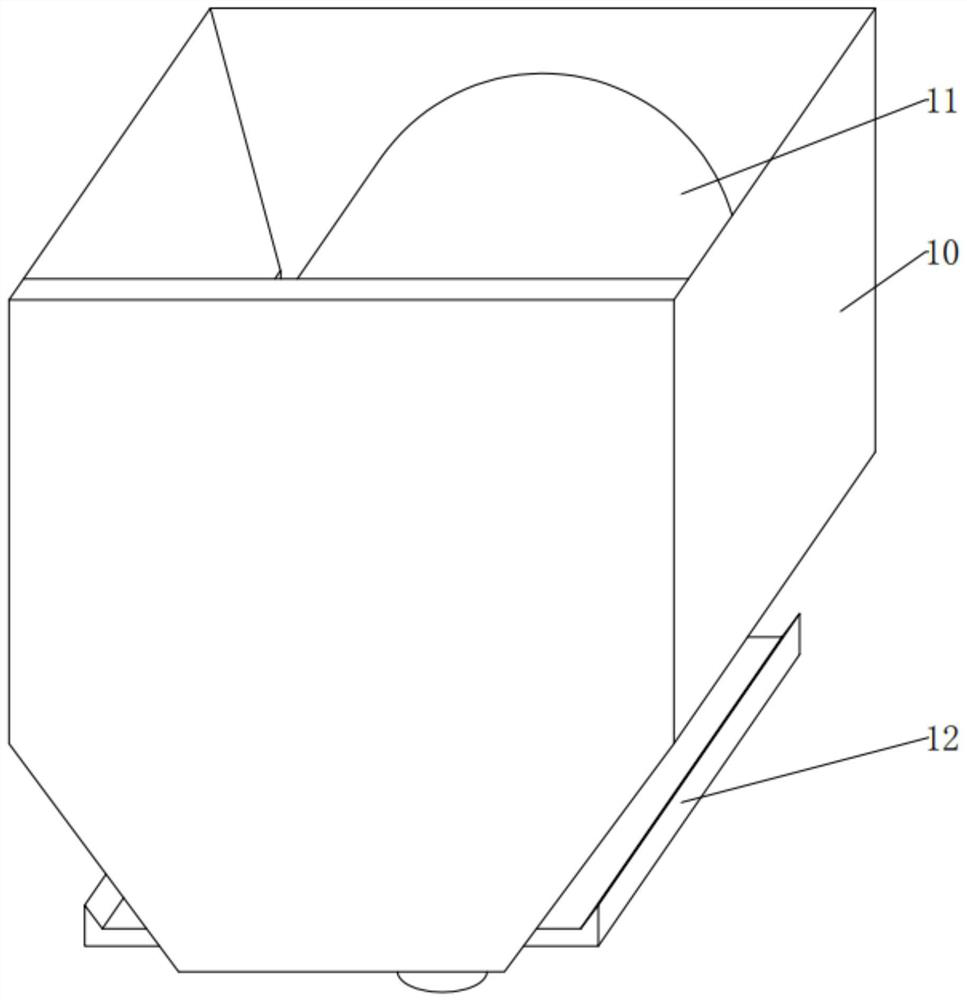

[0060] see Figure 4 , Figure 6-7 Compared with Embodiment 1, the embodiment of the present invention differs in that: the glue guide assembly 11 includes:

[0061] The convex plate 13 is fixedly installed in the middle of the upper end between the front and rear inner walls of the glue drop trough 10. The material of the convex plate 13 is boron-iron alloy. The letter "C" shape of °, there is an interval between the bottom of the left and right outer walls of the convex plate 13 and the left and right inner walls of the glue drop groove 10;

[0062] Here, the convex plate 13 and its appearance are set as upwardly convex on a longitudinal section and rotated 90° clockwise in the shape of the letter "C", which is to facilitate the arched shape to drop the top convex plate 13 of the glue drop chute 10. The glue can slide down to the left and right along the outer wall of the convex plate 13, and finally lead to the right guide plate 15 and the left guide plate 16, so that the...

Embodiment 3

[0074] see Figure 4-8 Compared with Embodiment 1, the embodiment of the present invention differs in that the flow aid assembly 12 includes:

[0075] The long groove, the left end and the right end of the glue drop groove 10 are obliquely opened with a hollow long groove from the middle end to the bottom position;

[0076] The long groove here is to separate the small cavity and the large cavity together with the longitudinal plate 17 to store quicklime powder and water respectively, and when the vertical plate 17 falls, the quicklime powder in the small cavity is moved along the direction of the long groove. The bottom slides into the large cavity and heats up after contacting with water;

[0077] The short groove, the middle upper end of the long groove is vertically provided with a hollow short groove, and the bottom of the short groove extends downward to the upper end of the left and right ends of the glue drop groove 10 and is provided with an outlet;

[0078] The sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com