Multidirectional wood cutting device for wooden door processing

A cutting device and multi-directional technology, applied in wood processing appliances, manufacturing tools, forming/shaping machines, etc., can solve the problems affecting wood cutting efficiency, legacy, affecting the stable placement of the wood to be cut, etc., to improve cutting accuracy, Improve work efficiency and improve cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

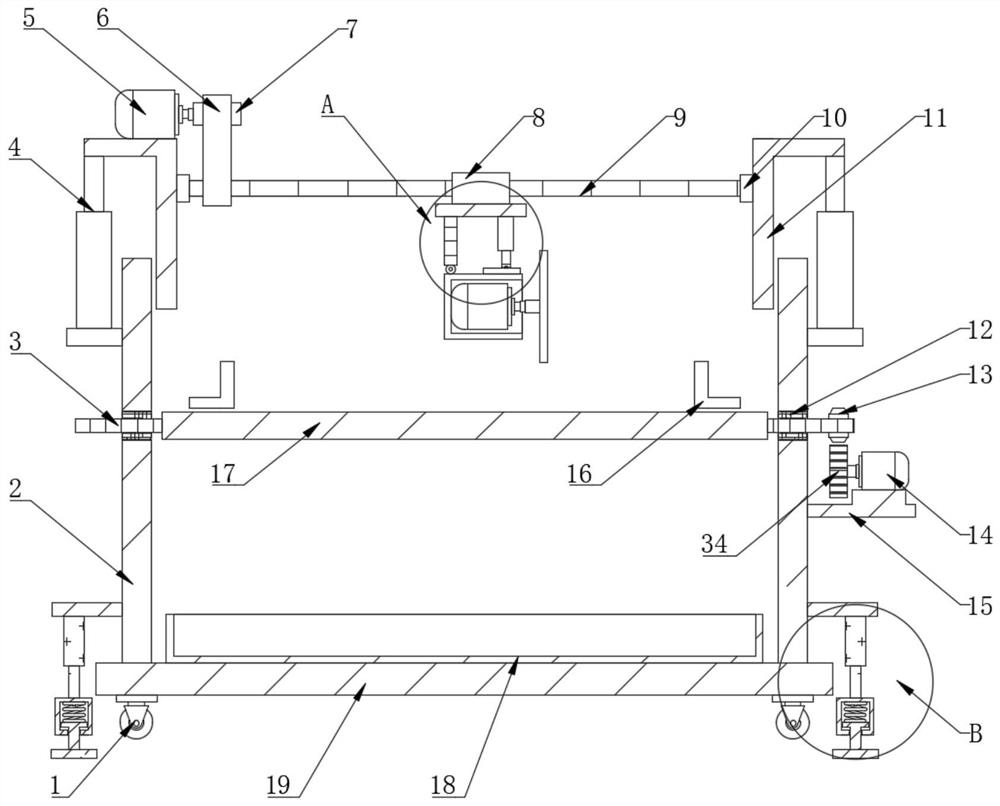

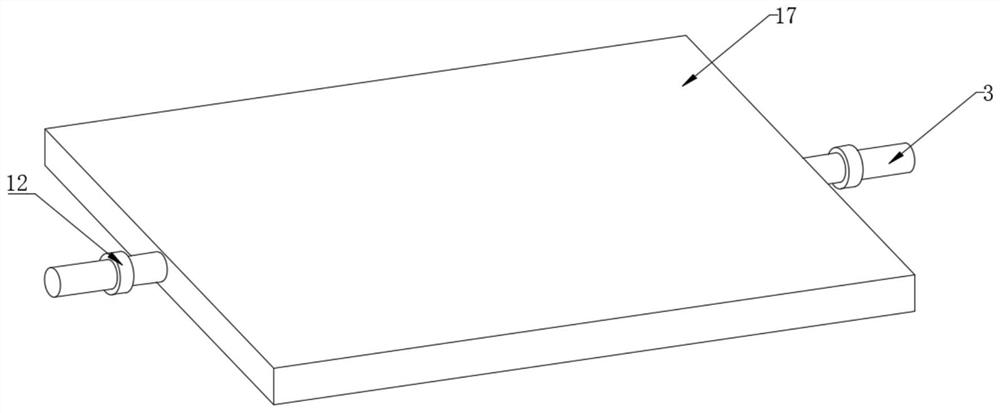

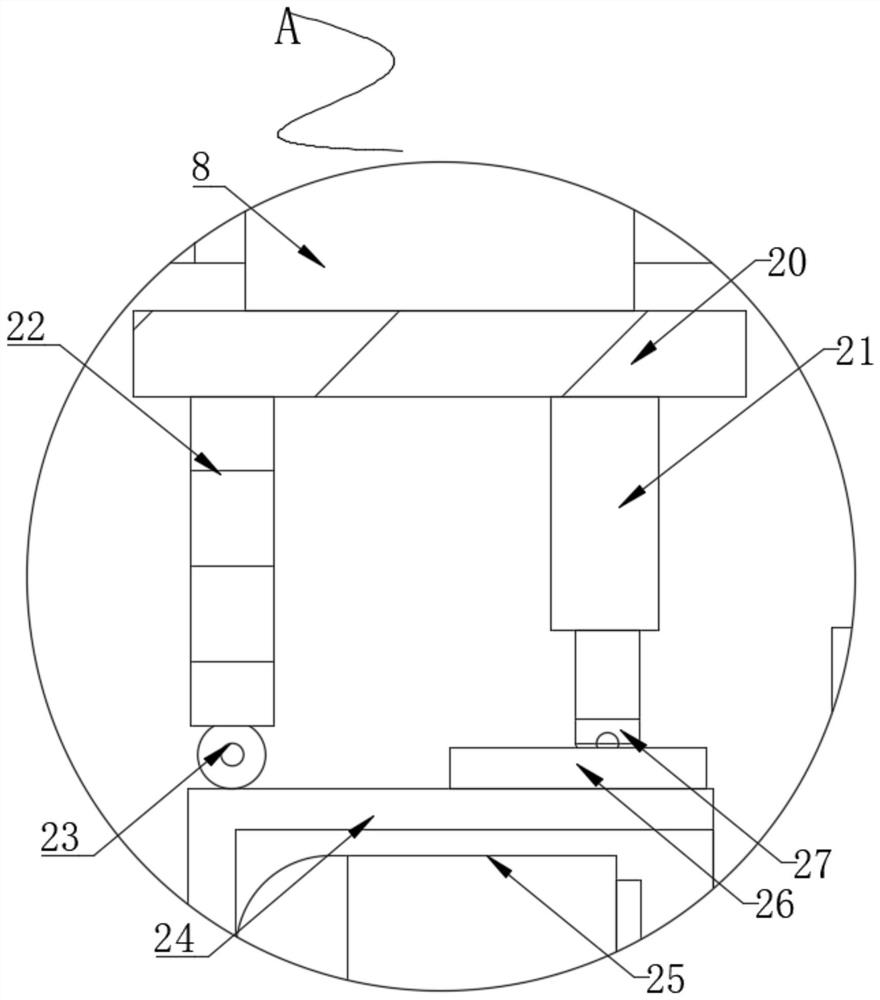

[0025] see Figure 1~3 , in an embodiment of the present invention, a multi-directional wood cutting device for wooden door processing includes a base 19, the top of the base 19 is connected with an ash receiving groove 18, and both sides of the top of the base 19 are connected with supporting side plates 2, and the bottom of the base 19 The four corners of the end are equipped with moving wheels 1, and a wood placement plate 17 is arranged between the two supporting side plates 2. A second rolling bearing 12 is installed on one side of the supporting side plate 2, and a first rolling bearing 12 is installed on the top of the supporting side plate 2. Hydraulic cylinder 4, the both sides of wood placement plate 17 are all connected with the first turning rod 3, and one side of the support side plate 2 that is positioned at the right side of wood placement plate 17 is connected with mounting seat 15, and the top of mounting seat 15 is equipped with second Motor 14, one end of th...

Embodiment 2

[0033] refer to figure 1 with 4 , a multi-directional wood cutting device for wooden door processing. Compared with Embodiment 1, this embodiment also includes a reaction force plate 29 connected to one side of the support side plate 2, and a hydraulic jack 28 is installed at the bottom end of the reaction force plate 29. , the bottom of hydraulic jack 28 is connected with installation box 33, and the inboard of installation box 33 is equipped with damping spring 30, and the bottom of installation box 33 is provided with movable block 32, and the bottom end of movable block 32 is connected with shock-absorbing base 31.

[0034] Wherein, the top of damping spring 30 is connected with the inner wall of installation box 33, and the bottom end of damping spring 30 is connected with the top of movable block 32, and the bottom end of installation box 33 offers through hole, and movable block 32 is arranged on the through hole. the inside of the hole.

[0035] Working principle: wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com