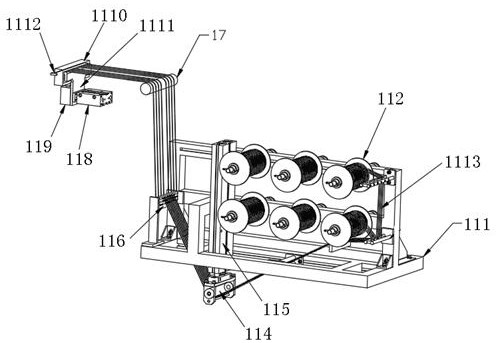

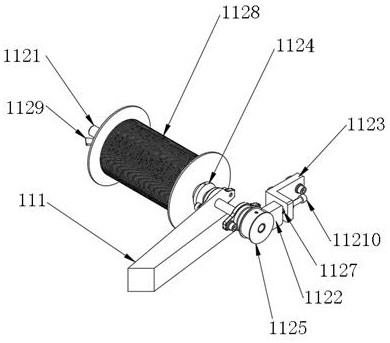

A jacquard machine component vertical hook injection molding feeding machine

A component and injection molding technology, applied in coating and other directions, can solve the problems of increasing defect rate, low labor efficiency and productivity, and high work intensity, so as to ensure the pass rate and consistency, the action process is efficient and compact, and the operation Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

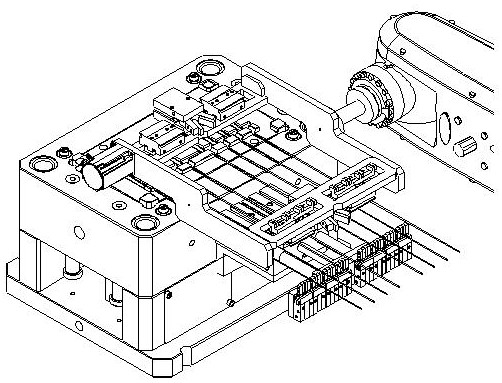

[0042] 7. The mold assembly is moved forward to the injection molding position as a whole, and one end of the wire is connected with the vertical hook by injection molding.

[0043] 8. After the injection molding of one end of the through wire is completed, the mold is reset to the upper through wire position (outside the injection molding machine) again.

[0054] 3, save the land occupation of equipment, save labor, improve production efficiency and production capacity, and reduce production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com