Filled solid tire for low speed heavy duty vehicle

A low-speed heavy-duty, solid tire technology, applied to wheels, vehicle parts, non-pneumatic tires, etc., can solve the problems of low permanent deformation, poor handling, and weakened tire compression performance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

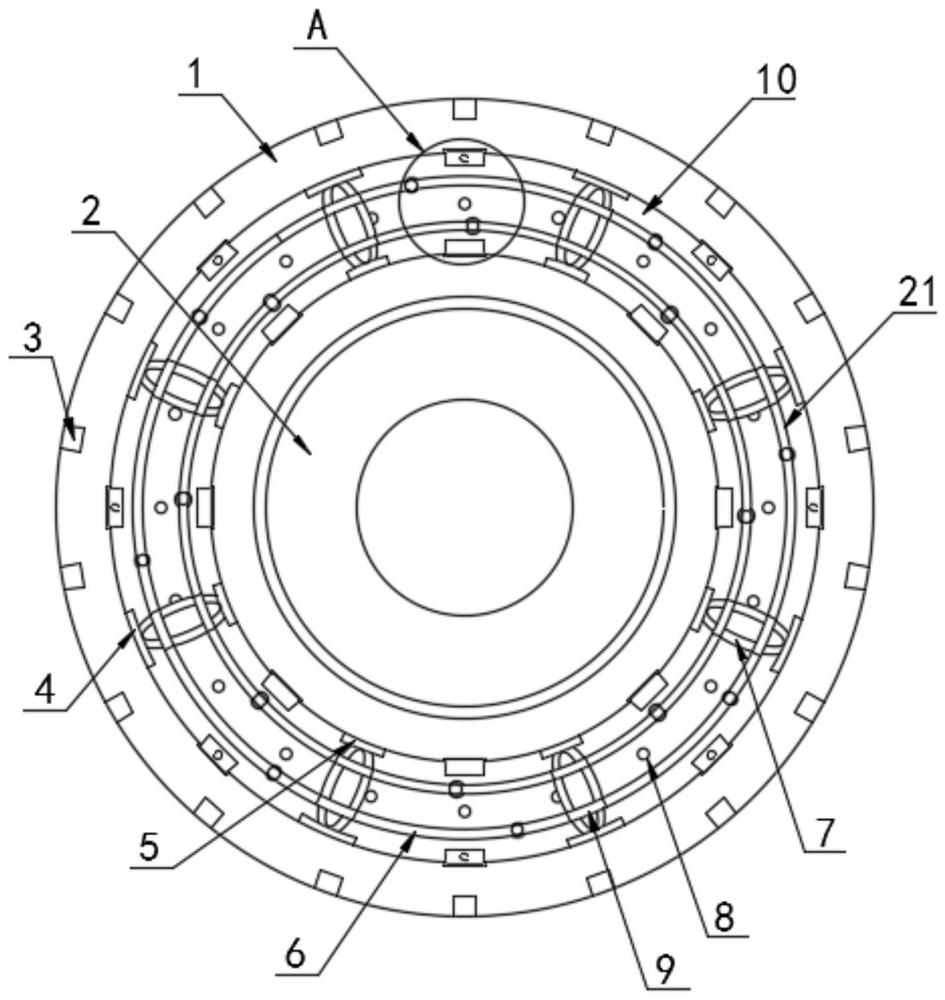

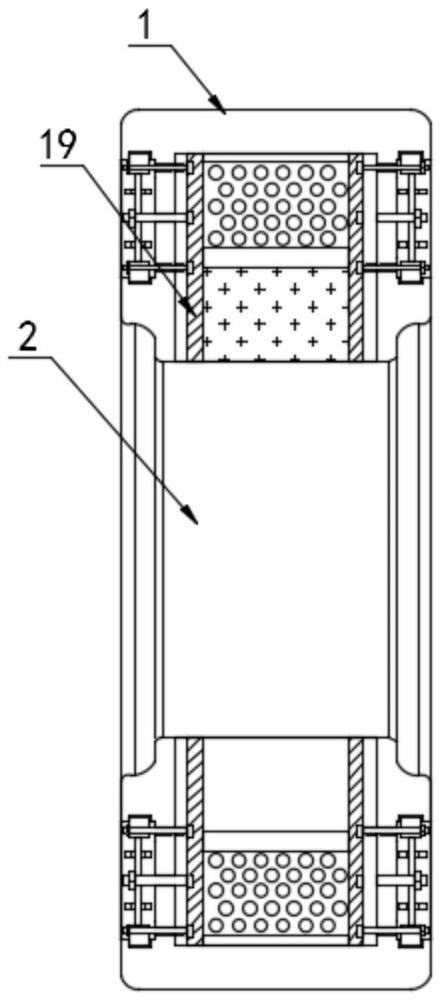

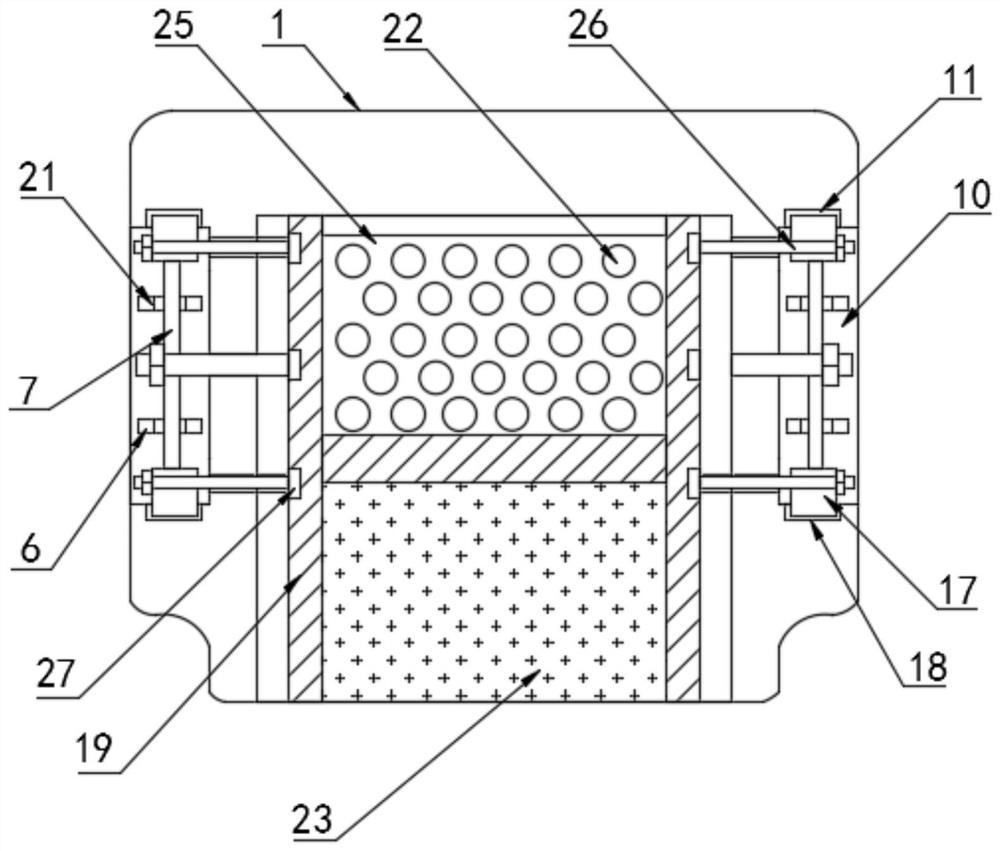

[0029] Refer to the attached Figure 1-7 A filled solid tire for low-speed heavy-duty vehicles in this embodiment includes a tire entity 1 and a hub 2, the inner wall of the top of the hub 2 is socketed on the tire entity 1, and a concave hole is opened on the tire entity 1. Groove 10, the inner wall of the top of the groove 10 is provided with a rectangular groove 11, the inner wall of the bottom of the groove 10 is provided with a rectangular groove 2 18, and the circumference of the side wall of the tire entity 1 is evenly provided with ventilation and cooling holes 8 and the fixing hole 12, the rectangular groove one 11 and the rectangular groove two 18 inner walls insert the clamping block 17, the inner wall of the clamping block 17 is threadedly connected to the pin rod 26, and the pin rod 26 is away from one end thread of the clamping block 17 Connect the reinforcing rod 29, the reinforcing rod 29 is provided with an internal thread hole 27, one end of the reinforcing r...

Embodiment 2

[0038] Refer to the attached Figure 8 , the difference from Embodiment 1 is: the tire entity 1 is also provided with a rectangular heat dissipation groove 30, and the rectangular heat dissipation groove 30 is provided with two groups, and the two groups of rectangular heat dissipation grooves 30 are located on the front side of the tire entity 1. In the middle: the function of the rectangular cooling groove 30 is to enable the tire entity 1 to dissipate heat quickly, and to increase the grip performance of the tire entity 1 to prevent skidding;

[0039] The specific implementation scenarios are:

[0040] Compared with Embodiment 1, when using the present invention, the outer ring 19 is placed in the accommodation chamber 25 of the tire entity 1, and the upper side of the accommodation chamber 25 of the tire entity 1 is filled with the cushioning soft rubber elastic ball 22, and through the internal thread The hole 27 is threaded with the pin rod 26 to connect the outer ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com