Movement driving mechanism of constructional engineering construction hoisting device

A hoisting device and construction engineering technology, which is applied in building construction, construction material processing, construction, etc., can solve the problems of manpower consumption, reduced work efficiency, and high viscosity of lubricating paste, so as to reduce manual operations and achieve good automatic effects , improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

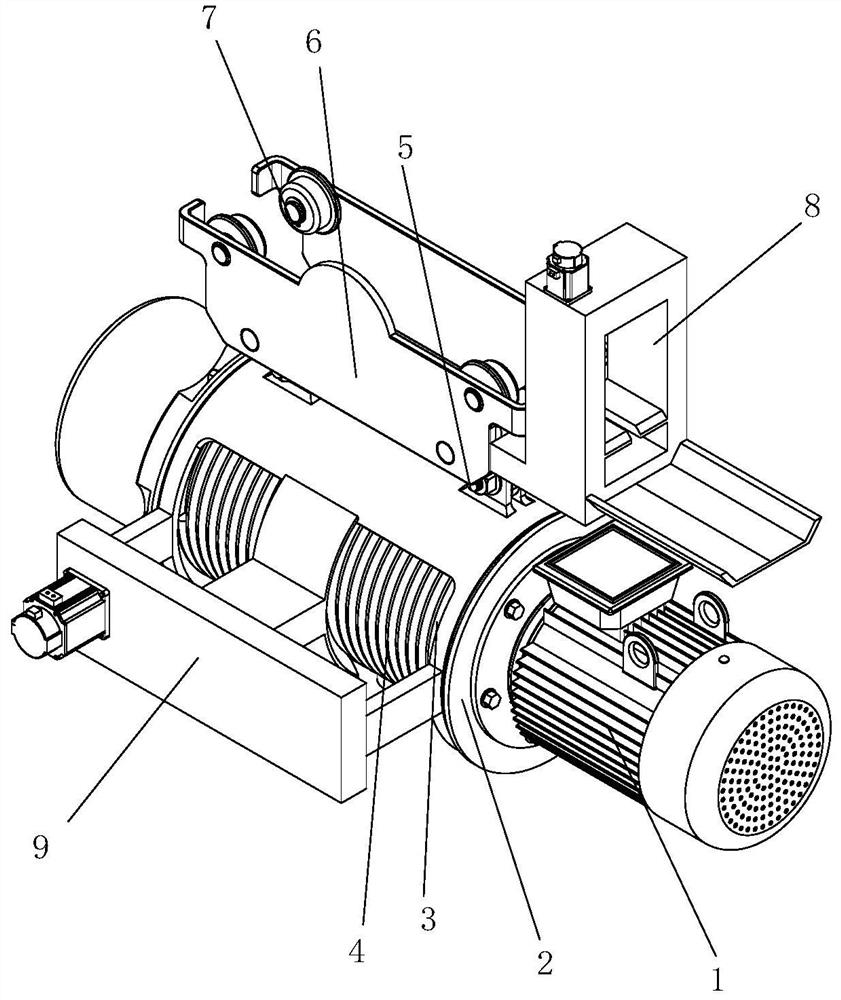

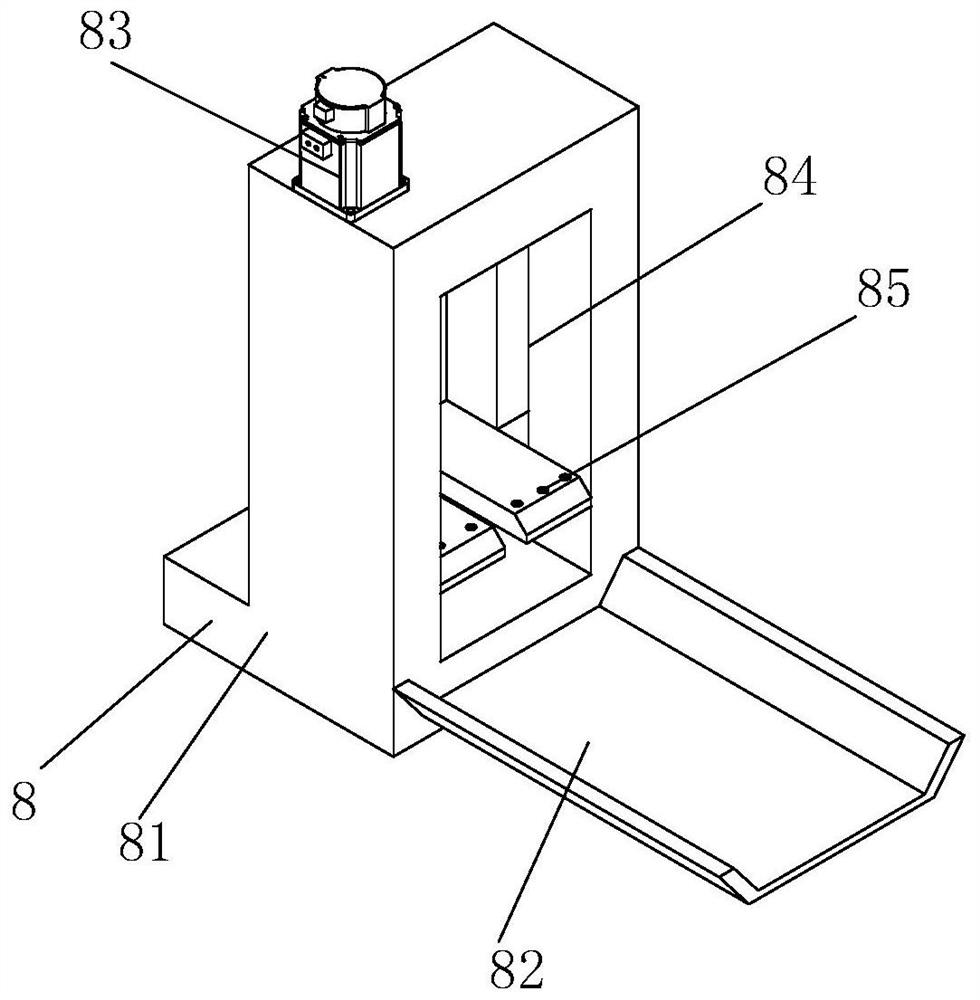

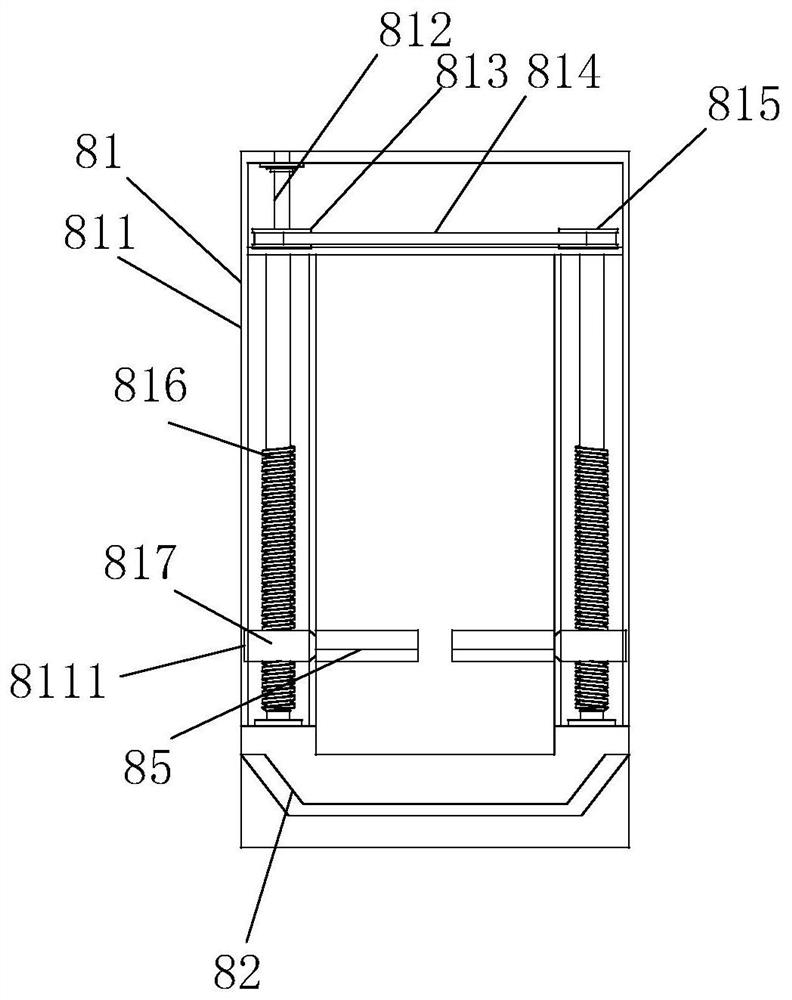

[0031] see figure 1 , the present invention provides a mobile driving mechanism of a building construction hoisting device through improvement, including a first motor 1, the left side of the first motor 1 is fixed on the right side of the fixed shell 2, and a rotating roller 3 is installed in the middle of the fixed shell 2 , the right side of the rotating roller 3 is connected to the output shaft on the left side of the first motor 1, the outer diameter surface of the rotating roller 3 is wound with a steel rope 4, the left and right ends of the top of the fixed shell 2 are fixed with connecting pieces 5, and the top of the connecting piece 5 is connected to the guide frame 6 is locked, the upper end of the guide frame 6 and the front and rear ends are rotatably connected with the guide wheel 7, the right side of the guide frame 6 is provided with a cleaning device 8, and the middle part of the front end of the fixed shell 2 is connected with the auxiliary device 9.

[0032]...

Embodiment 2

[0039] The present invention provides a mobile drive mechanism for a building construction hoisting device through improvement. The scraper 853 is trapezoidal, and the bottom of the scraper 853 is smooth. To the right end of the plate body 851, after being embedded, it is fixed with the plate body 851 by three sets of bolts, the fixing effect is good, and the disassembly and assembly are convenient; the scraper 942 is in the shape of an arc, and the front, rear, left, and right sides of the scraper 942 are chamfered, which is convenient Scraper 942 disperses and wipes evenly the lubricating paste on the steel rope in the lubricating work.

[0040] The present invention provides a mobile driving mechanism of a building construction hoisting device through improvement, and its working principle is as follows;

[0041] First, when the equipment needs to be used, first install the driving mechanism on the hoisting device, and then connect the electric control equipment on the hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com