Clamp and clamping method for semiconductor laser bars

A laser and semiconductor technology, applied in metal material coating process, vacuum evaporation coating, coating, etc., can solve the problems of mechanical center point offset, bar falling off, thermal deformation, etc., and achieve thin fixture thickness and low cost , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

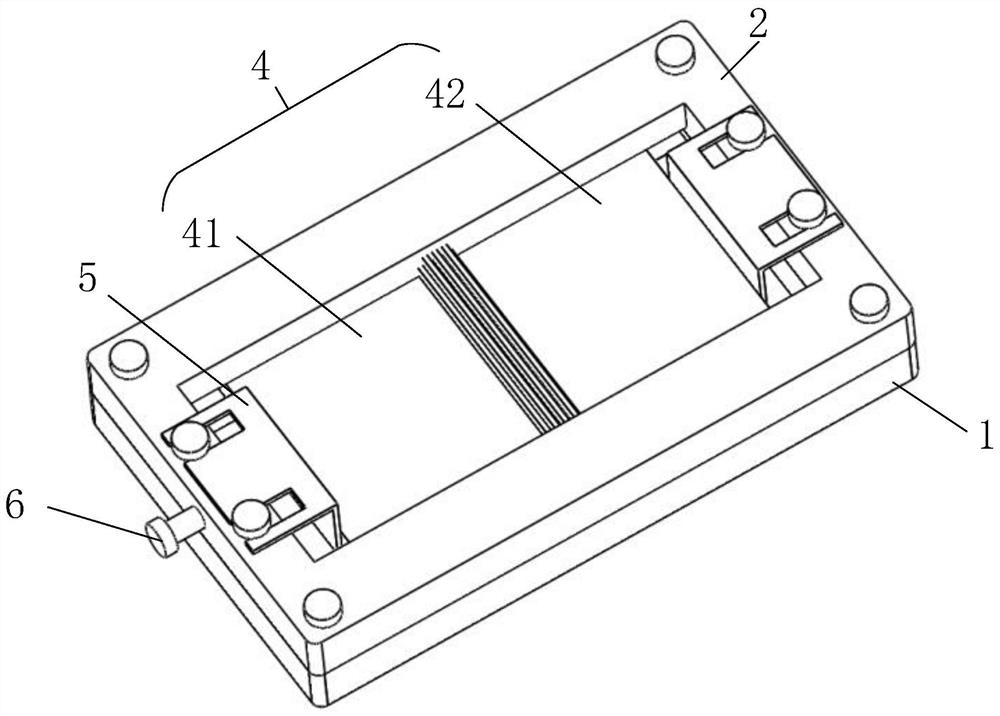

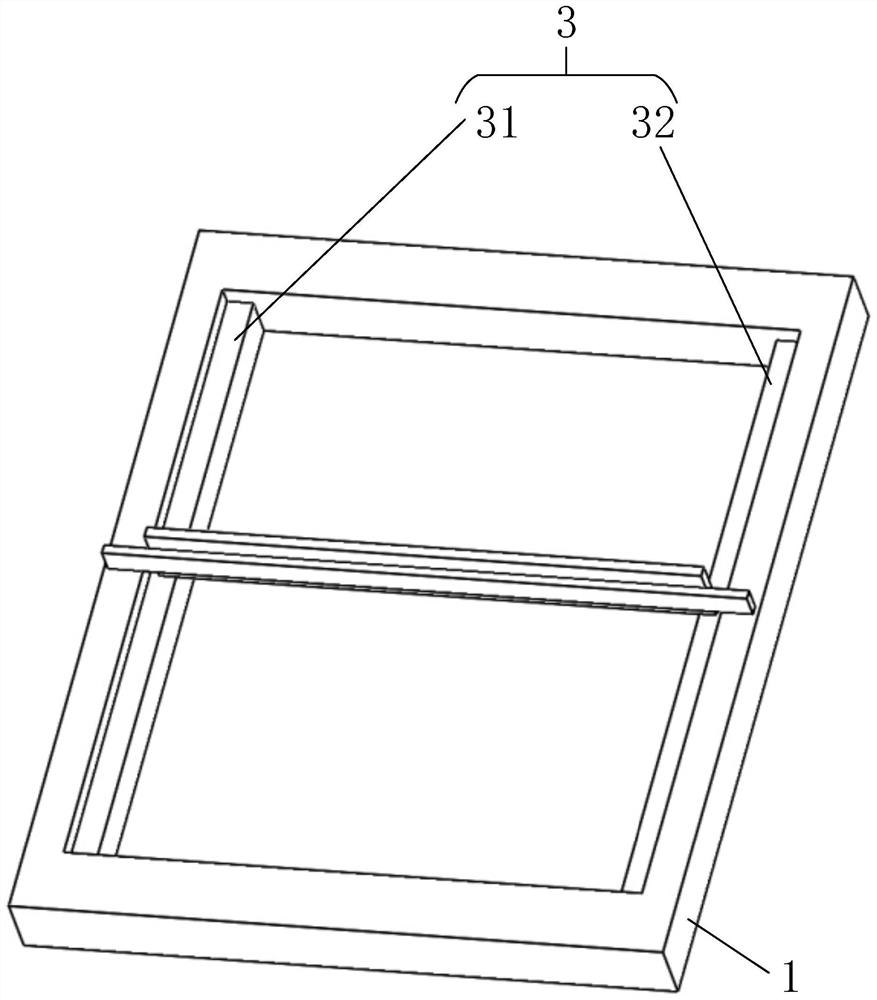

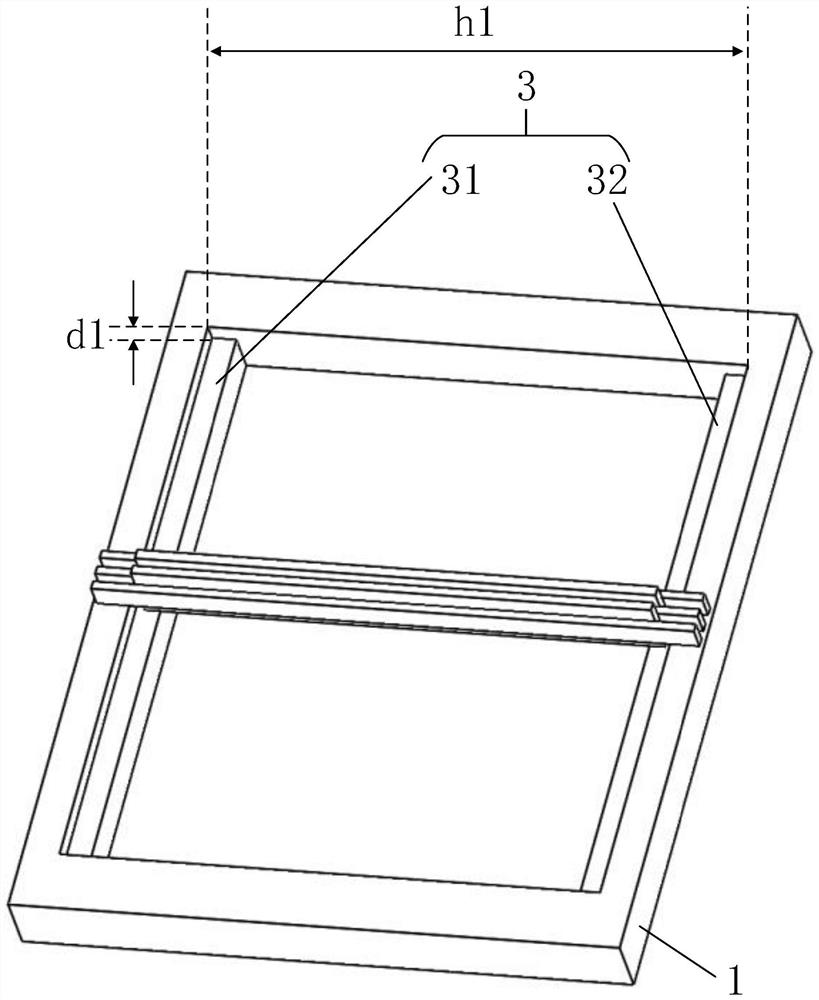

[0059] Embodiment 1 of the present invention provides a fixture for semiconductor laser bars, such as figure 1 and figure 2 As shown, it includes the lower outer frame 1 of the fixture, the upper outer frame 2 of the fixture, the step 3 for placing the bar, the bar gasket 4, the thrust shrapnel 5 and the thrust bolt 6 and, specifically:

[0060] The step 3 includes a first step 31 and a second step 32, and is symmetrically arranged on opposite inner sides of the lower outer frame 1 of the fixture, and the upper surface of the step 3 is lower than the lower outer frame of the fixture. 1; wherein, the first step 31 and the second step 32 are used to hold up the two ends of the laser bar; the upper surface of the clamp lower frame (1), or the first step ( 31) and the second step (32), to hold up the positions of the two ends of the laser spar;

[0061] Described bar spacer 4 comprises first spacer 41 and second spacer 42, is arranged on described step 3 and / or fixture lower fr...

Embodiment 2

[0083] Embodiments of the present invention provide a clamping method for a semiconductor laser bar, using the clamp for a semiconductor laser bar described in Embodiment 1, such as Figure 15 As shown, clamping methods include:

[0084] In step 201, the laser bars are placed on the step 3, and the laser bars are placed on the lower frame 1 of the fixture; wherein, the placement form is that the laser bars and the laser bars are placed alternately.

[0085] In step 202, after the placement of the bar and the spatula is completed, place the bar spacer 4 on both sides of the laser bar structure to be clamped formed by the laser bar and the laser spar, and cover the fixture after the placement is completed The upper outer frame 2 is used to cover both sides of the laser spar and the bar gasket, and expose the laser bar from the middle area of the upper outer frame 2 of the fixture.

[0086] In step 203 , the thrust elastic piece 5 is pushed forward by the thrust bolt 6 , so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com