Modular scroll compressor

A scroll compressor and modular technology, applied in the field of scroll compressors, can solve problems such as restricting the production efficiency and product competitiveness of enterprises, increasing the manufacturing cost of scroll compressors, etc., so as to improve production competitiveness, improve assembly efficiency, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further detailed in connection with the accompanying drawings and specific examples.

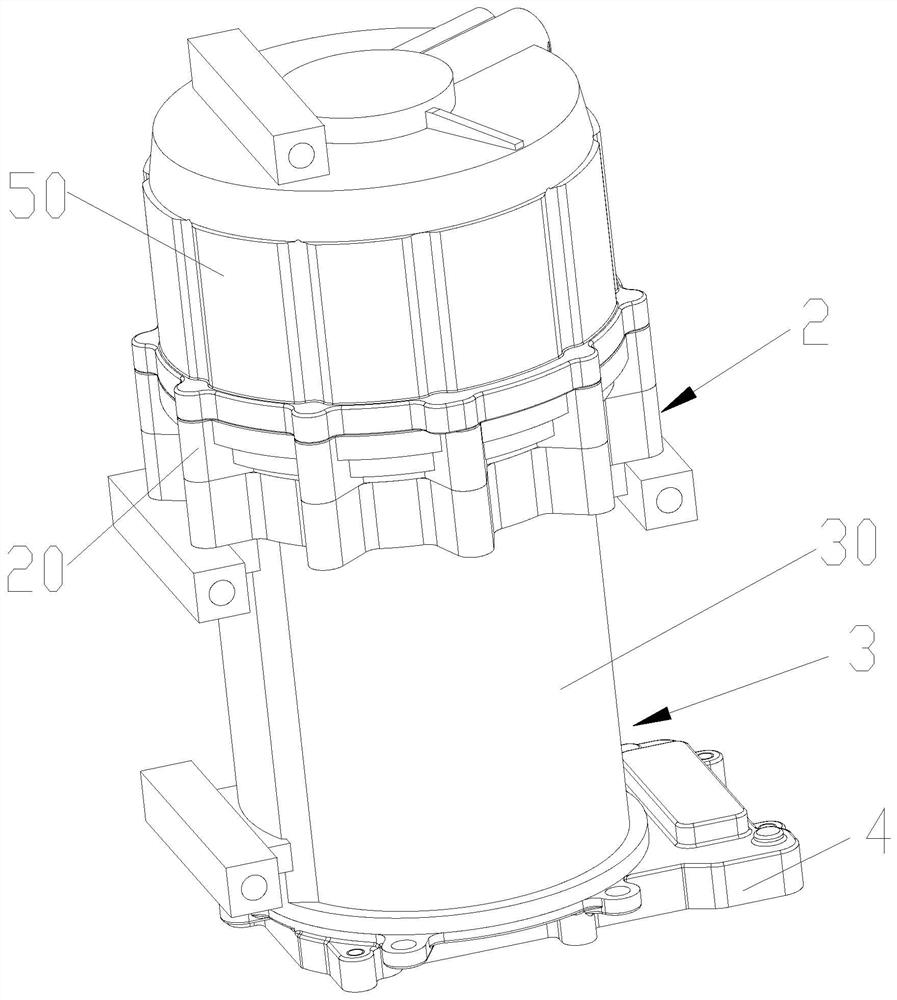

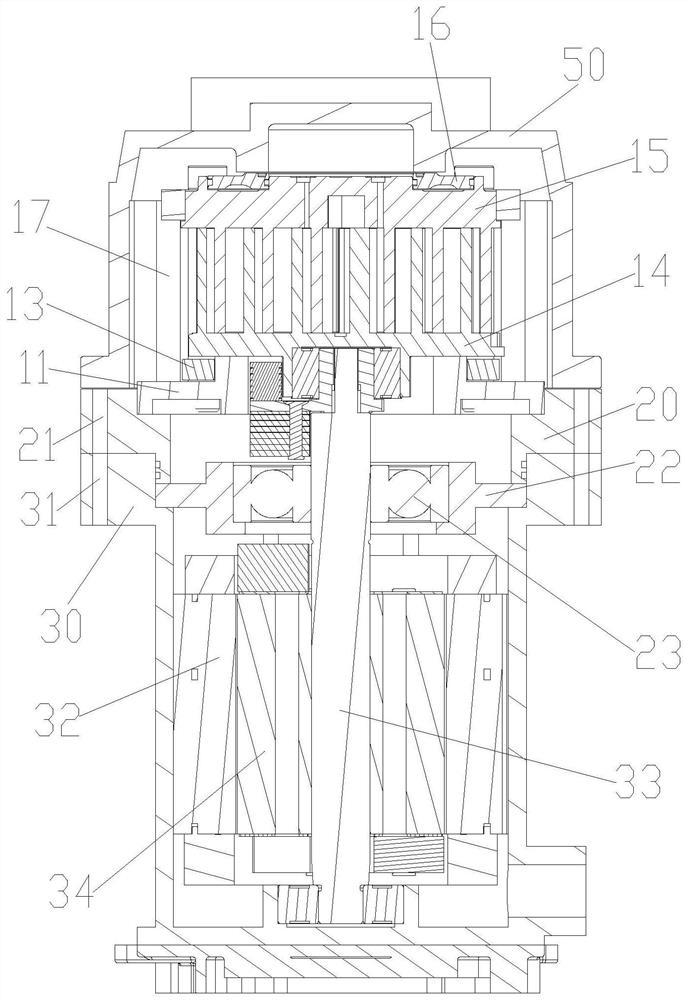

[0026] See Figure 1-6 , A modular scroll compressor according to the present invention, includes a top cover 50, a scroll portion 1, an adapter portion 2, a drive unit 3, and a controller module 4; a circumferential direction projection at the bottom of the top cover 50. A plurality of threaded holes are provided; the controller module 4 is mounted at the bottom of the drive unit 3, the controller module for controlling the operation of the scroll compressor.

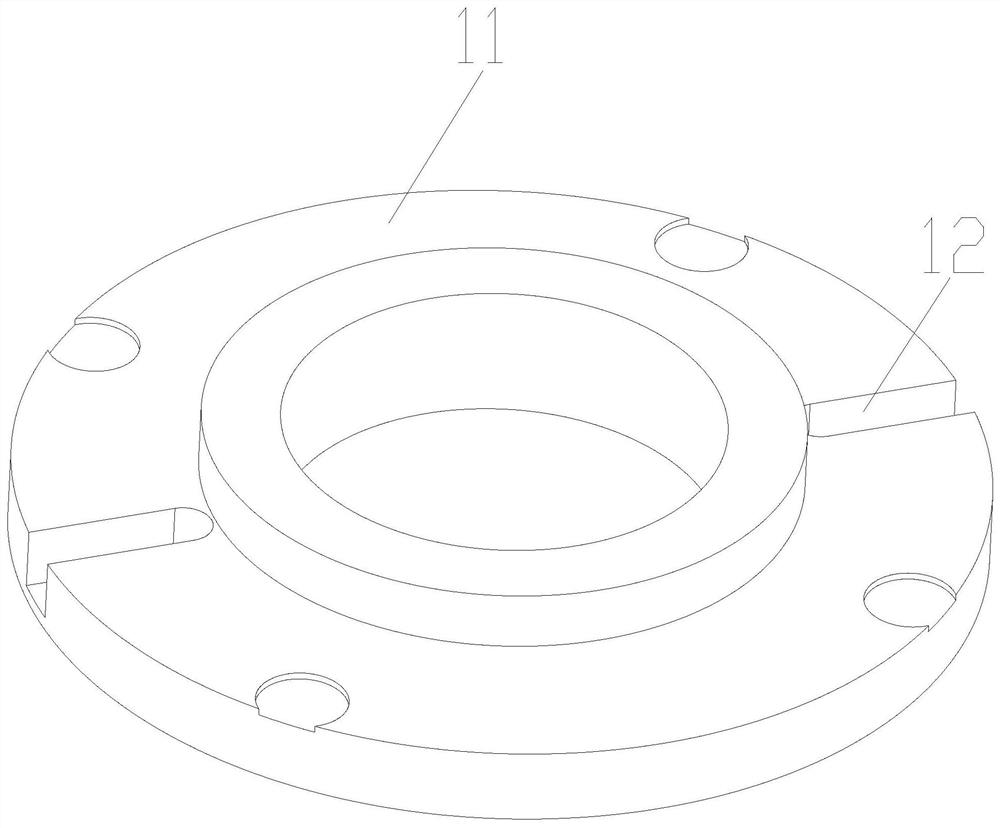

[0027] Wherein, the scroll portion 1 includes in the top cover 50, the scroll portion 1, includes a movable scroll stop plate 11, a slide groove 12 is opened on the movable scroll stop 11; The sliding groove 12 is provided with a slidable inner cross slip ring 13; the inner cross slip ring 13 is provided with a movable scroll 14 in conjunction with it; the above-mentioned arranging vortex is adapted Switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com