A monitoring device and monitoring method for deformation points of steel components

A technology for monitoring devices and steel components, applied to measuring devices, instruments, etc., can solve the problems of difficult placement of prisms, various structural forms, and variable measurement angles, and achieve the effects of improving monitoring accuracy and efficiency, quick installation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

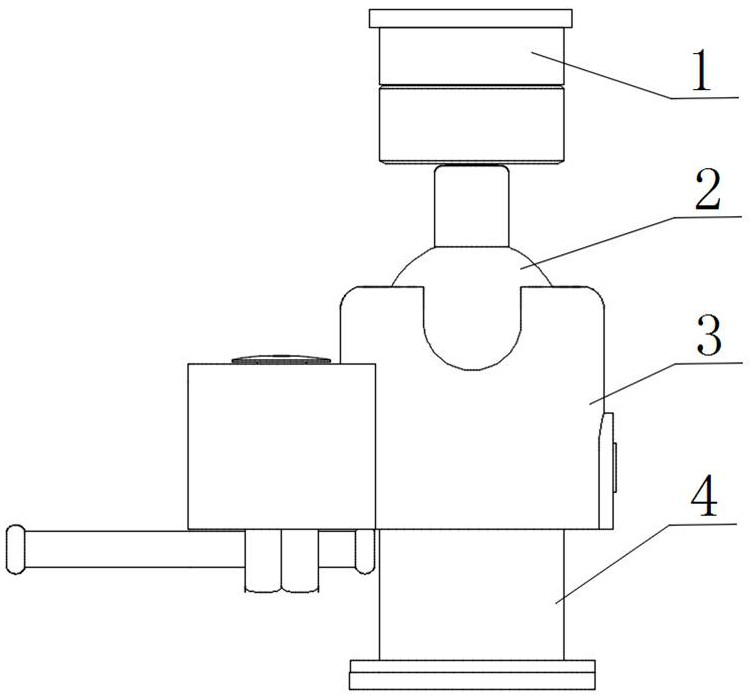

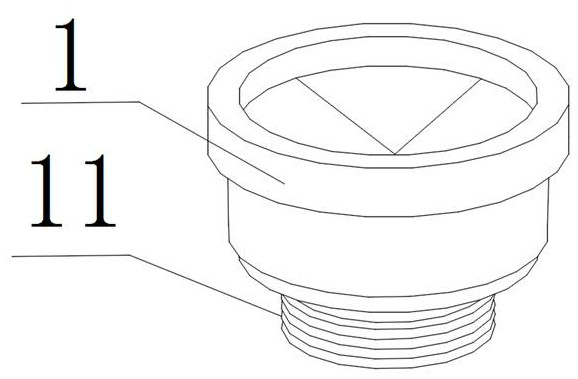

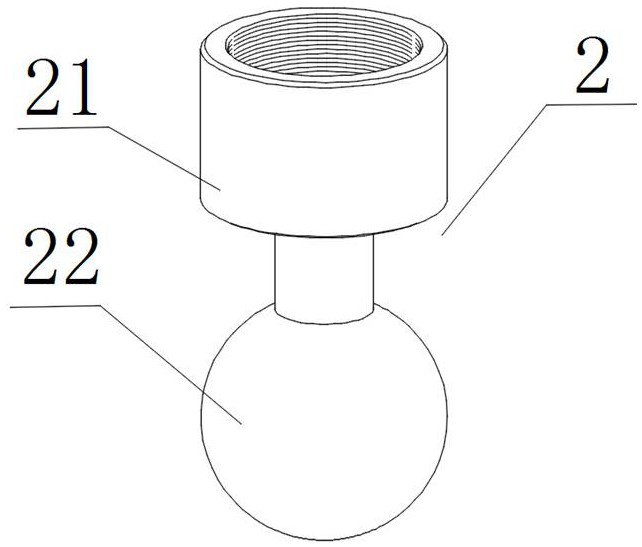

[0031] The invention provides a monitoring device for deformation points of steel components. The monitoring device for deformation points of steel components is used in conjunction with a total station for measuring base stations, such as Figure 1-8 As shown, the monitoring device for the deformation point of the steel member includes: a prism lens 1 , a cardan shaft head 2 , a clamp 3 and a base 4 . The universal shaft head 2 includes an adapter 21 and a rotating shaft head 22. One end of the rotating shaft head 22 is a spherical structure, and the other end is a cylindrical structure. The cylindrical structure is fixedly connected. The upper end inside the clamp 3 is a hollow structure matched with the spherical structure. The spherical structure is set in the hollow structure. One end of the base 4 is set inside the clamp 3 and connected with the spherical structure. The other end of the base 4 is magnetic. structure, adsorbed on the steel member.

[0032]In a preferred...

Embodiment 2

[0038] The invention provides a method for monitoring the deformation point of a steel component using a monitoring device for the deformation point of a steel component. The method for monitoring the deformation point of a steel component includes the following steps: It is installed in the hollow structure where the upper end of the clip body 31 matches with the spherical structure. Set one end of the adapter tube 41 inside the hoop body 31, and connect it with the spherical structure, and fix the adapter tube 41 and the right side of the hoop body 31 through the positioning screw 32, and through the locking screw 33 and the locking nut 34 fix the left side of the adapter tube 41 and the clamp body 31, and install the locking handle 35 on the locking nut 34. Install the adapter 21 of the universal shaft head 2 on the rotating shaft head 22 , and install the prism lens 1 on the upper end of the adapter 21 . The first base 42 is installed on the lower end of the adapter tube ...

Embodiment 3

[0042] Introduce the specific process of the monitoring method of the steel component deformation point of a preferred embodiment of the present invention below:

[0043] Firstly, the spherical structure of the rotating shaft head 22 in the universal shaft head 2 is installed in the hollow structure where the upper end of the clamp body 31 fits with the spherical structure. Set one end of the adapter tube 41 inside the hoop body 31, and connect it with the spherical structure, and fix the adapter tube 41 and the right side of the hoop body 31 through the positioning screw 32, and through the locking screw 33 and the locking nut 34 fix the left side of the adapter tube 41 and the clamp body 31, and install the locking handle 35 on the locking nut 34. Install the adapter 21 of the universal shaft head 2 on the rotating shaft head 22 , and install the prism lens 1 on the upper end of the adapter 21 . The first base 42 is installed on the lower end of the adapter tube 41, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com