A kind of quality evaluation method of ceftriaxone sodium butyl rubber stopper for injection

A technology for quality evaluation of ceftriaxone sodium, which is applied in the field of quality evaluation of ceftriaxone sodium for injection, can solve problems such as non-compliance with the inspection items of "clarity of solution", drug dissolution becoming turbid, and affecting drug quality, etc., to achieve accurate High performance, simple steps, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment relates to a method for evaluating the quality of ceftriaxone sodium butyl rubber stopper for injection, comprising the following steps:

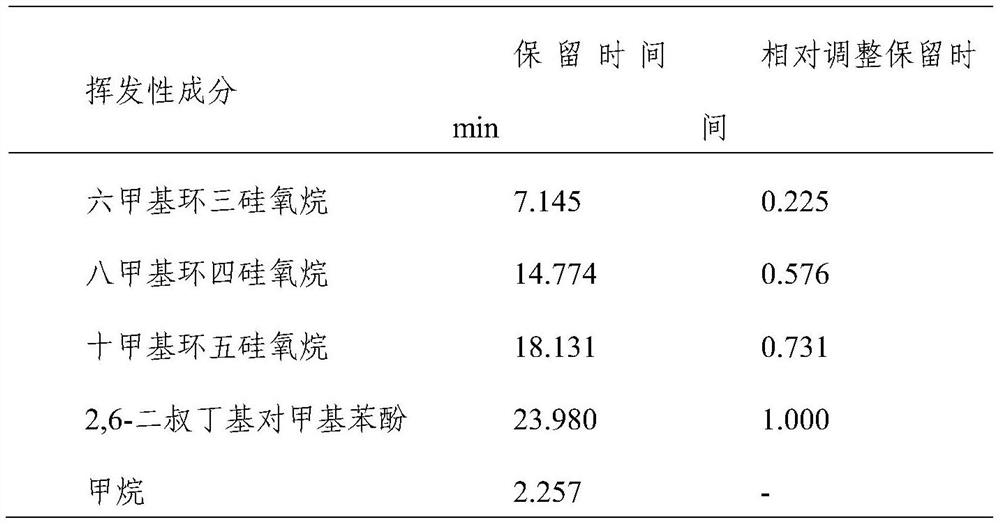

[0041] 1) Determine the volatiles hexamethylcyclotrisiloxane, octamethylcyclotetrasiloxane, decamethylcyclopentasiloxane and 2 in the butyl rubber stopper in the sample to be tested by headspace gas chromatography 6-di-tert-butyl-p-cresol;

[0042] The detection conditions are: chromatographic column: 5% phenyl-95% methyl siloxane;

[0043] Carrier gas: nitrogen; flow rate 1.0ml / min;

[0044] Column temperature program: 50°C maintained for 10min, 10°C / min raised to 170°C, maintained for 20min;

[0045] Headspace conditions: 121°C for 30min; use methane to determine the dead time of the chromatography system (t 0 );

[0046] 2) Select octamethylcyclotetrasiloxane concentration 0.0518mg / ml as detection standard;

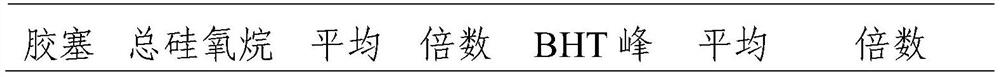

[0047] Four batches of butyl rubber stoppers produced by the same manufacturer were analyzed acco...

Embodiment 2

[0052] The present embodiment relates to a method for evaluating the quality of ceftriaxone sodium butyl rubber stopper for injection, comprising the following steps:

[0053] 1) Measure the volatiles hexamethylcyclotrisiloxane, octamethylcyclotetrasiloxane, decamethylcyclopentasiloxane and BHT in the butyl rubber stopper in the sample to be tested by headspace gas chromatography;

[0054] The detection conditions are: chromatographic column: 5% phenyl-95% methyl siloxane;

[0055] Carrier gas: nitrogen; flow rate 1.0ml / min;

[0056] Column temperature program: 50°C maintained for 10min, 10°C / min raised to 170°C, maintained for 20min;

[0057] Headspace conditions: 121°C for 30min; use methane to determine the dead time of the chromatography system (t 0 );

[0058] 2) Select the octamethylcyclotetrasiloxane concentration as 0.0518mg / ml as the detection standard;

[0059] Three batches of butyl rubber stoppers produced by the same manufacturer were analyzed according to the...

experiment example

[0063] The rubber stoppers of Example 1 and Example 2 were used for the production of ceftriaxone sodium for injection. The turbidity of the turbidity solution was compared, and it was found that the turbidity of the turbidity solution was lower than that of No. 1 turbidity solution, which proved that the quality of the rubber stoppers of Examples 1 and 2 met the requirements.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap