PCBA automatic test fixture

An automatic testing and jig technology, applied in the field of gluing machines, can solve the problems of inability to perform optical testing and low testing efficiency, and achieve the effects of improving testing accuracy, increasing testing items, and stabilizing position parameter calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

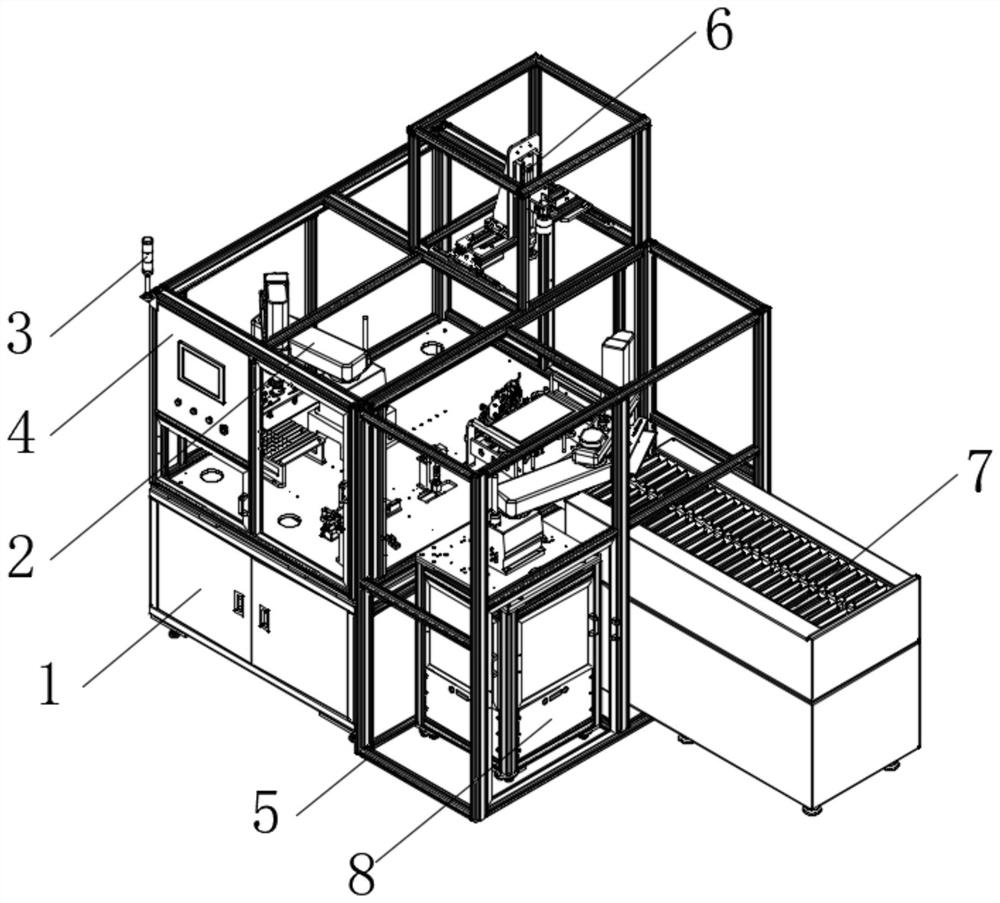

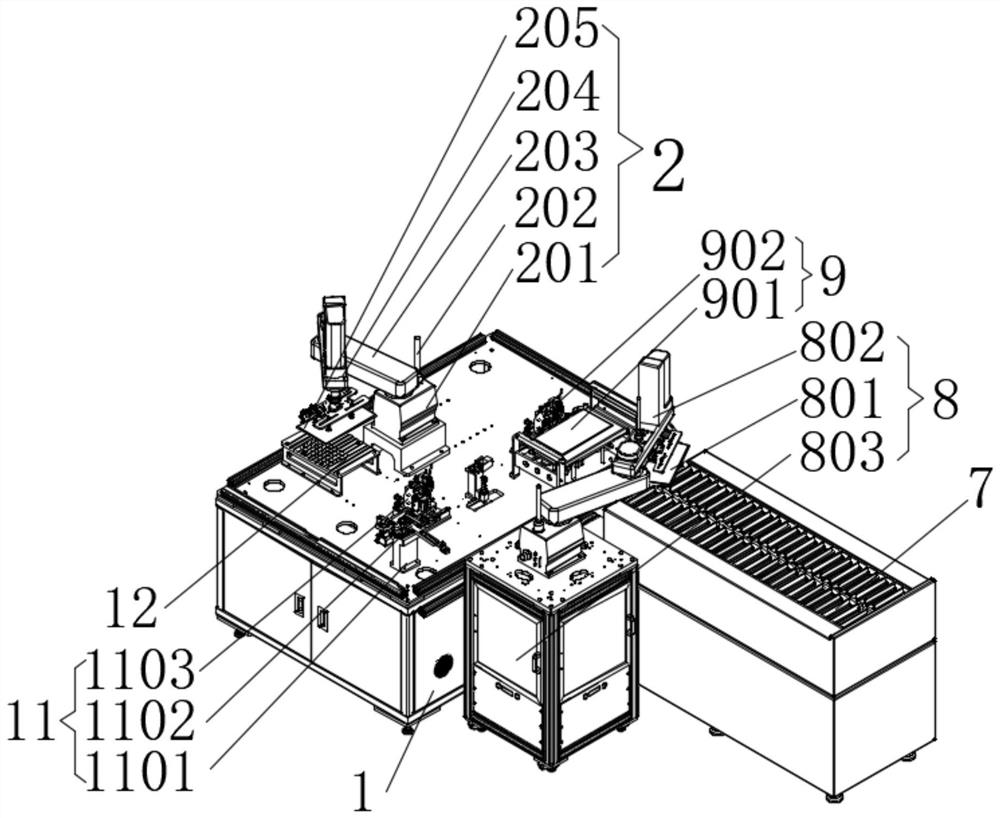

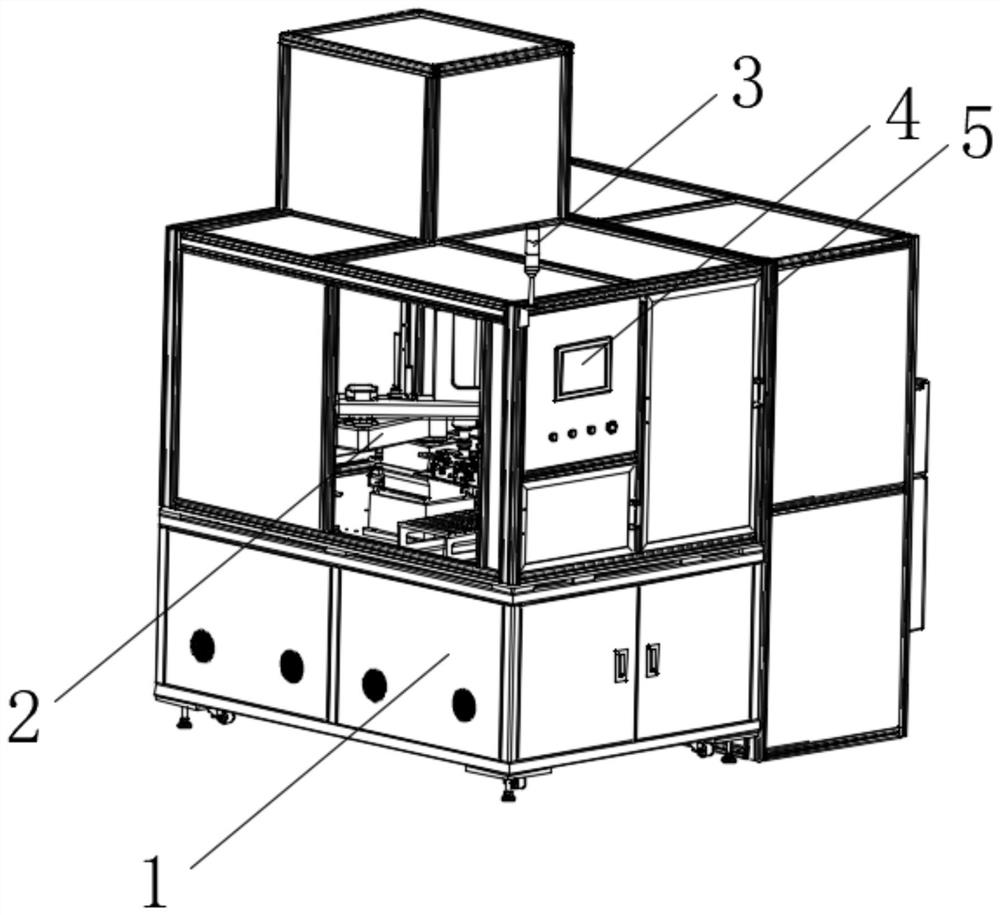

[0032] refer to Figure 1-7, a PCBA automatic test fixture, including a test equipment main body 1 and a detection table 10 installed in the middle of the inner cavity of the test equipment main body 1, a raw material support 12 is fixedly installed on the edge of the detection table 10, and a test equipment main body 1 is provided with a The main body frame 5, the top horizontal position of the main frame 5 is bolted and fixed with the test assembly 6, the side of the test equipment main body 1 is provided with a discharge track 7, the discharge track 7 adopts a chain plate track, and the chain plate surface of the discharge track 7 Through holes are evenly opened on the top, and the discharge track 7 is provided with a push-out telescopic rod at the plane projection position of the discharge assembly 8. The top corner of the main frame 5 is vertically fitted and fixed with an indicator light 3, and the front of the main frame 5 is fitted There is a control host 4, a feeding ...

Embodiment 2

[0039] refer to figure 2 The feeding assembly 2 of a PCBA automatic test fixture includes a main body bracket 201 that is bolted and fixed to the surface of the detection table 10. The top of the main body bracket 201 is pivotally connected with a main body rotating frame 203, and the end of the main body rotating frame 203 is axially connected with a The positioning support arm 206, the end of the positioning support arm 206 is pivotally connected with the shifting end 204, the end of the shifting end 204 is connected with the feeding jaw 205, and the side of the main body support 201 is vertically equipped with a detection tube 202 for detecting The tube 202 is integrated with position, acceleration, and angle sensors. The top of the detection tube 202 is fitted with the physical origin of the detection device. The main body rotating frame 203 and the positioning support arm 206 are all made of aluminum alloy sheet metal. The main body rotating frame 203 and the positioning ...

Embodiment 3

[0042] refer to Figure 7 A test assembly 6 of a PCBA automatic test fixture includes a longitudinal slide rail 601 that is bolted and fixed to the main body frame 5. The top of the longitudinal slide rail 601 is vertically provided with a horizontal slide rail 603. The longitudinal slide rail 601 and the horizontal slide rail A sliding platform 602 is arranged between the rails 603, and the top of the horizontal sliding rail 603 is slidably connected with a horizontal sliding platform 604, and the middle part of the top surface of the horizontal sliding platform 604 is fixed with a micro-motion sliding rail 610, and the middle part of the micro-motion sliding rail 610 is provided with an auxiliary Reinforcing rib 609, the front of auxiliary reinforcing rib 609 is bolted and fixed with vertical slide rail 608, and the front of vertical slide rail 608 is provided with detection sensor 606, and electric appliance is fixed between detection sensor 606 and the slide table of vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com