Rolling bearing fault analysis based on CNN and LSTM

A rolling bearing and fault classification technology, applied in the testing of mechanical components, character and pattern recognition, pattern recognition in signals, etc., can solve problems such as gradient disappearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

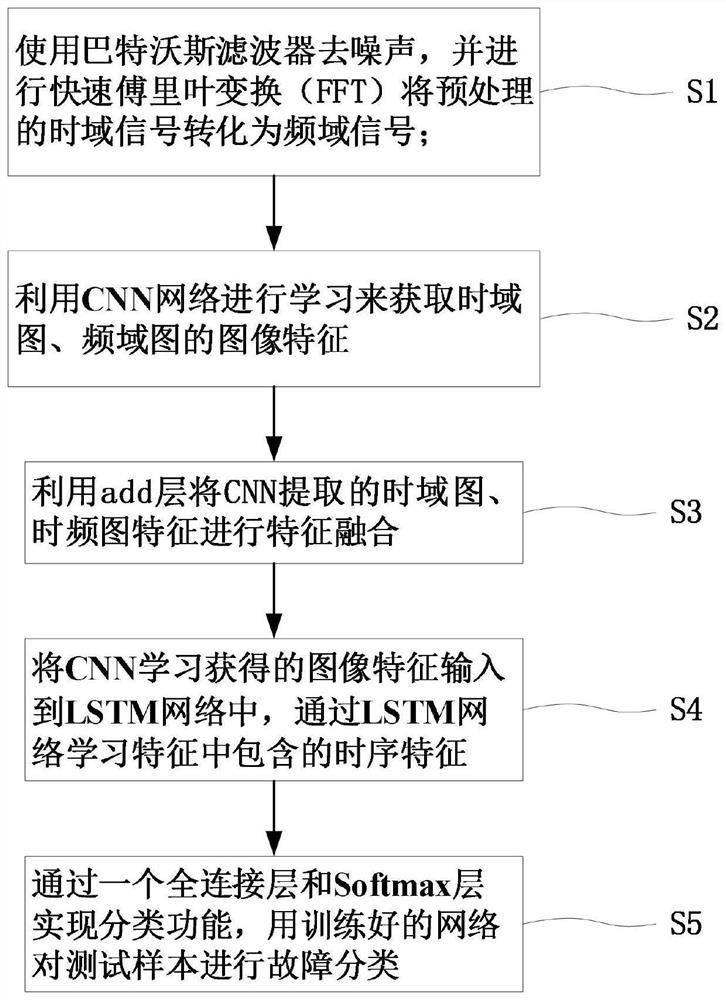

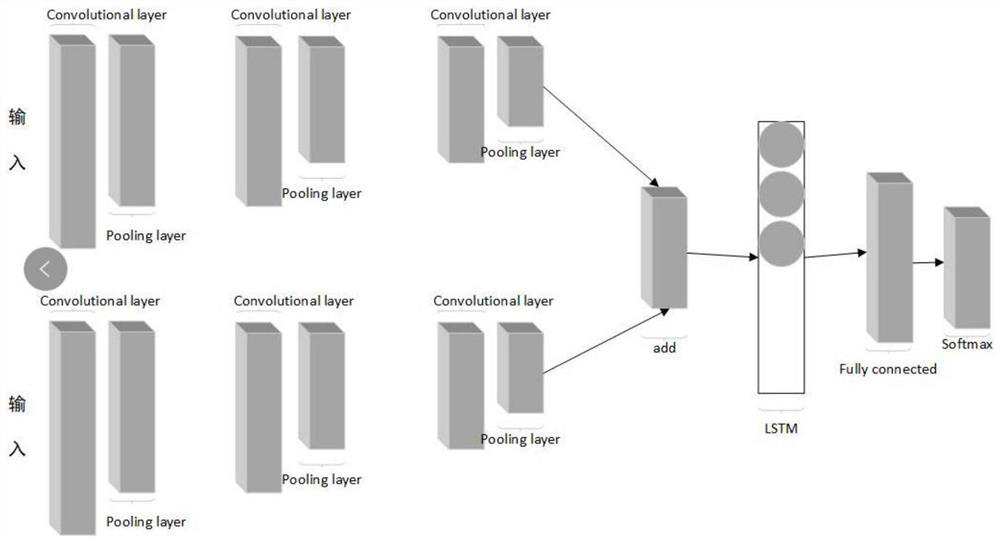

[0040] figure 1 It is a schematic flowchart of a rolling bearing fault analysis method based on CNN and LSTM according to an embodiment of the present application. see figure 1 It is known that a CNN and LSTM-based rolling bearing fault analysis method and system provided in the embodiment of the present application may include:

[0041] Step S1: Denoise the processed vibration data using a Butterworth Filter, and perform Fast Fourier Transform (FFT) to convert the preprocessed time-domain signal into a frequency-domain signal;

[0042] Step S2: using CNN network for learning to obtain the image features of the time domain map and the frequency domain map;

[0043] Step S3: performing image feature fusion through the add layer;

[0044]Step S4: Input the fused image features obtained by the add layer into the LSTM network, and further learn the time series features contained in the features through the LSTM network;

[0045] Step S5: realize the classification function thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com