Hybrid excitation brushless direct-current motor

A brushed DC motor and hybrid excitation technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of weak magnetic force of the magnet inside the motor, difficult inspection and maintenance of the internal parts of the motor, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

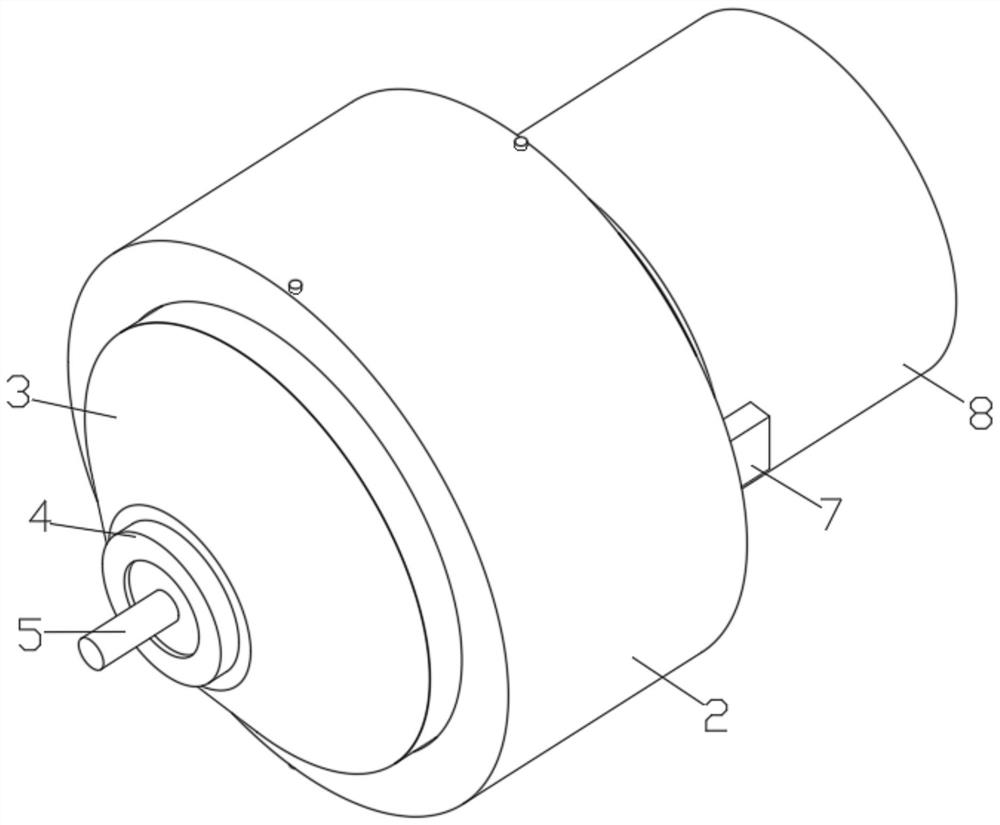

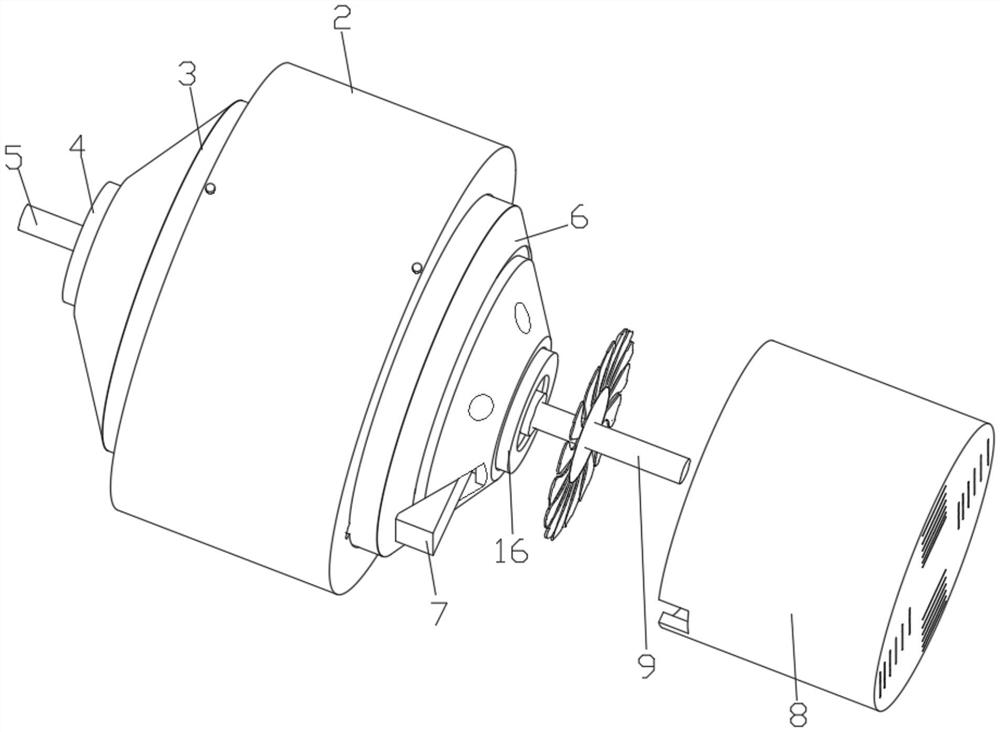

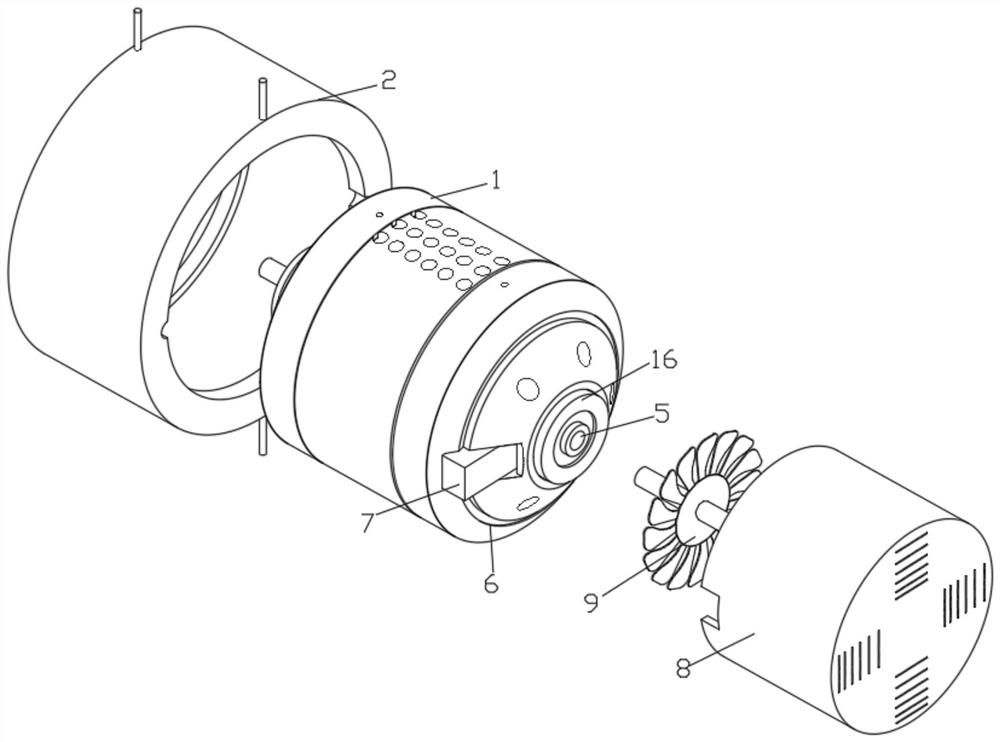

[0027] see Figure 1 to Figure 8, the present invention provides a technical solution: a hybrid excitation brushless DC motor, including a motor middle cover 1, the two sides of the motor middle cover 1 are provided with symmetrically distributed dense circular holes, and the outer sides of the motor middle cover 1 are opened There is an inwardly recessed annular notch, and the inside of the motor front cover 3 and the motor rear cover 6 is provided with a stepped annular notch, and the annular notches at both ends of the motor middle cover 1 are aligned with the motor front cover 3 and the motor rear cover 6. The internal stepped annular notches are adapted to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com