Microsensor-based breastfeeding volume measurement device

A flow measurement device and breastfeeding technology, applied in the direction of measurement device, sensor, temperature sensor, etc., can solve the problem of directly measuring the flow of breast milk without considering it, and achieve the effect of solving the separation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

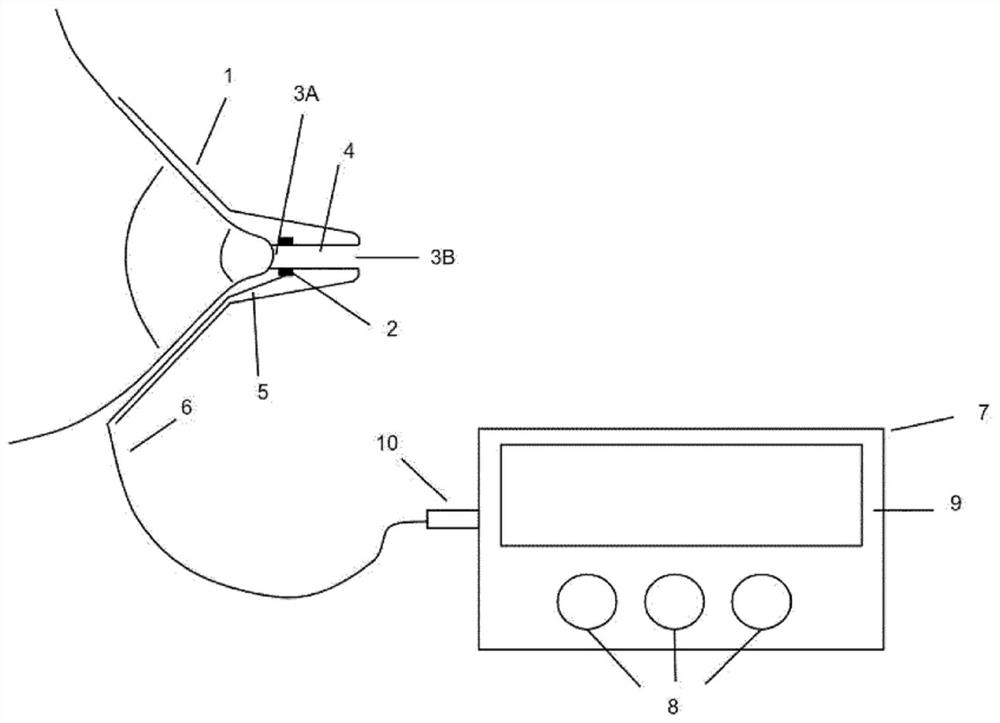

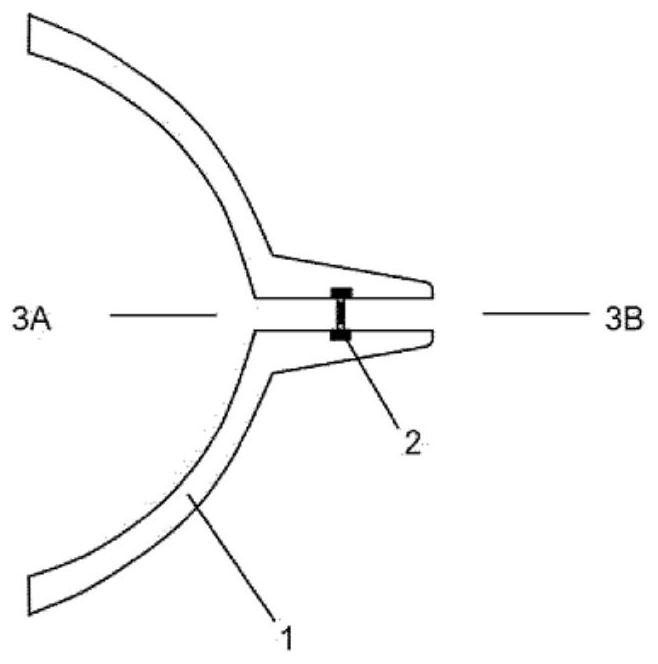

[0067] refer to figure 1 , provides a device comprising a nipple shield / nipple protector (1) made of silicone rubber, TPE or similar elastomeric material. It should be appreciated that the nature of this material renders the shield flexible and operable to conform to the shape of a woman's nipple. A flow channel (4) is defined in and extends through the shroud. The flow channel has a proximal nipple end which, in use, is adjacent the nipple when the shield is on the breast. The flow channel also has a distal nipple end which, in use, presents the baby's mouth when the shield is on the breast.

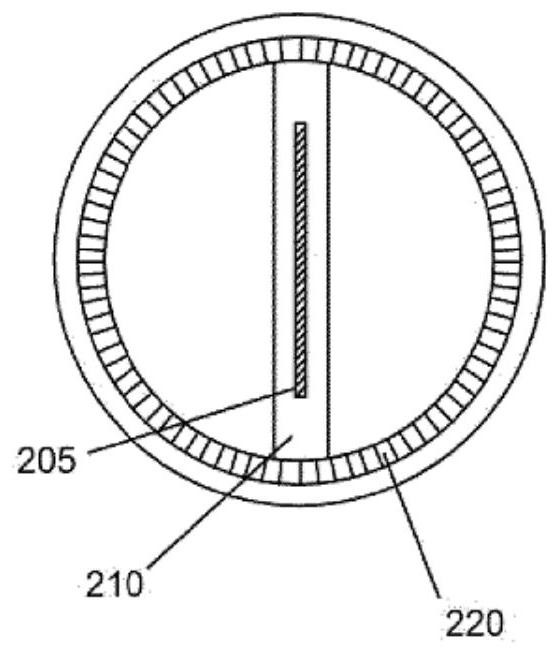

[0068] The device also includes a sensor module (2) located in a flow channel (4) defined in the shroud. To facilitate placement of the sensor module in the channel, the sensor can be fabricated on a plastic (or other food-contact safe material) support and can be integrated into the polymer shield by glue or other clamping during the molding process (1 )middle. In another embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com