Cleaning device for chemical industrial instrument

A technology for cleaning devices and instruments, which is applied in the direction of chemical instruments and methods, cleaning methods using tools, cleaning methods and utensils, etc. It can solve the problems that the device is not clean enough, the cleaning device cannot adapt to the cleaning effect, etc., and achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

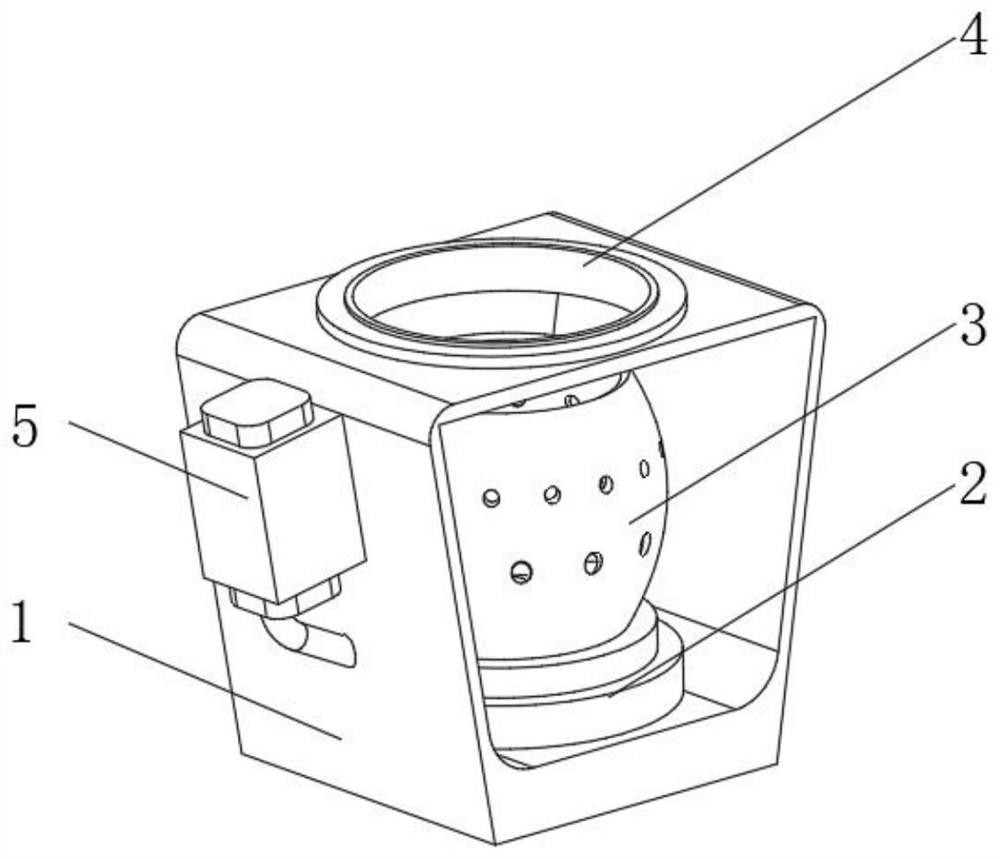

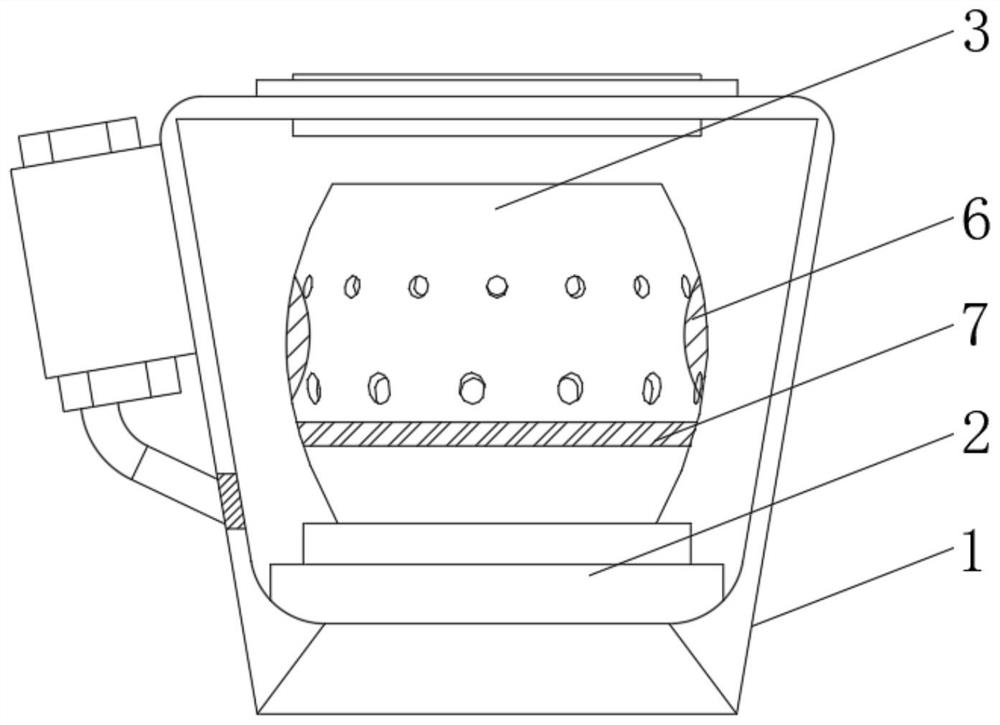

[0035] see Figure 1-3 , the present invention provides a technical solution: a chemical industry instrument cleaning device, including a device housing 1, a rotating seat 2 is installed under the inside of the device housing 1, an instrument placement frame 3 is arranged above the rotating seat 2, and the surface of the instrument placement frame 3 is opened There are through holes, and a cleaning agent loading tank 5 is provided on the side of the device housing 1, and the bottom of the cleaning agent loading tank 5 is connected to the device housing 1 through a conduit. An internal cleaning device 6 is provided, and a device fixing plate 7 is installed at the lower position inside the instrument rack 3;

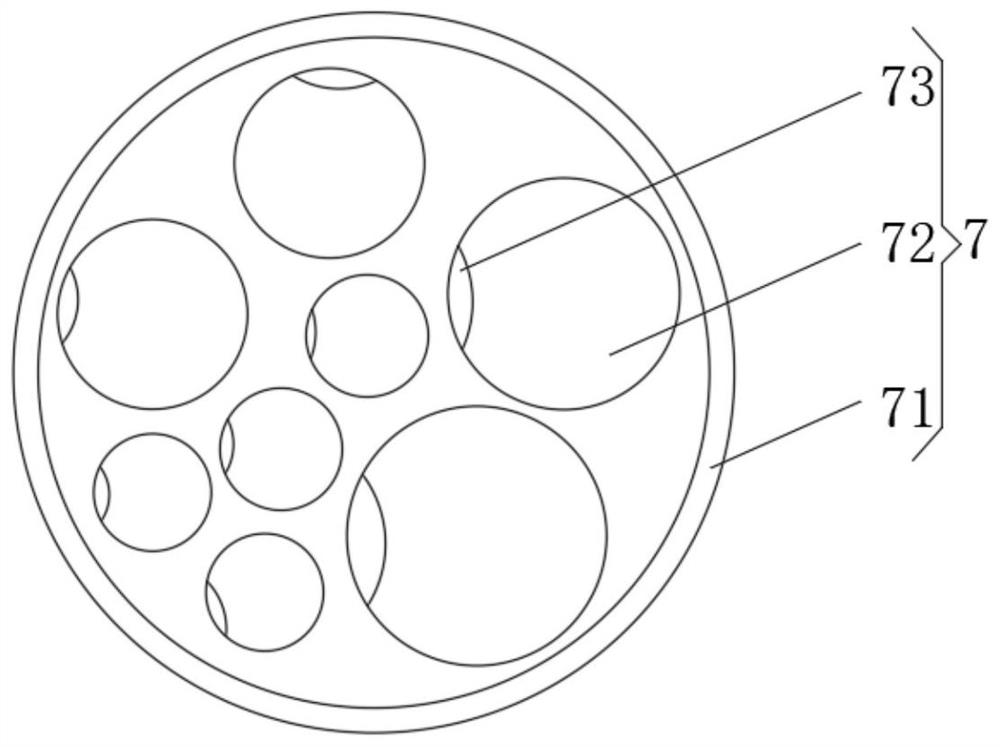

[0036] The device fixing plate 7 includes a plate body 71, and the inside of the plate body 71 is provided with an instrument placement plate hole 72, and the inside of the instrument placement plate hole 72 is provided with an elastic clamping piece 73, and the instrument...

Embodiment example 2

[0038] see Figure 1-6 , on the basis of the implementation case 1, the present invention provides a technical solution: the rotating seat 2 includes an inner disc body 21, a chute 22 is opened on the surface of the inner disc body 21, a return spring rod 23 is installed inside the chute 22, and the return spring rod 23 A movable terminal 24 is provided at a position away from the center of the inner disc body 21 , and a slot hole 25 is opened in the center of the inner disc body 21 .

[0039] The inner side wall of the end of the chute 22 far away from the center of the inner disc body 21 is provided with a power-connecting card position piece 26, and the outer side of the power-connecting card position piece 26 is provided with a power-connecting terminal 27. Stretch return spring bar 23, when movable terminal 24 in the device contacts with electric terminal 27 mutually, can send a deceleration signal now, this moment, interior motor can reduce rotational speed gradually.

[...

Embodiment example 3

[0044] see Figure 1-8 , on the basis of the implementation case 1 and the implementation case 2, the present invention provides a technical solution: the cleaning head 65 includes a cleaning outer terminal 651 and an inner support assembly 653, and the bottom ends of the cleaning outer terminal 651 and the inner support assembly 653 are provided with mounting seats 652, cleaning and resetting device 8 is provided at the protruding position inside the external terminal 651.

[0045] Cleaning and resetting device 8 comprises support outer frame 81 and elastic outer frame 82, through spherical connector 83 between support outer frame 81 and elastic outer frame 82, is installed between the arc inner side of support outer frame 81 and elastic outer frame 82 Arc elastic sheet 84, the outer side of arc elastic sheet 84 is equipped with cleaning roller 85, the cleaning reset device 8 that cleaning head 65 interior is provided with can make device play rigid support when cleaning, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com