Arc-shaped edge cutting device for stainless steel well lid production and implementation method thereof

A stainless steel and manhole cover technology, which is applied in the direction of shearing devices, knives used in shearing machine devices, and accessories of shearing machines, etc., can solve the problems of low efficiency of arc trimming and increase the workload of operators, and achieve easy maintenance , The effect of convenient installation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

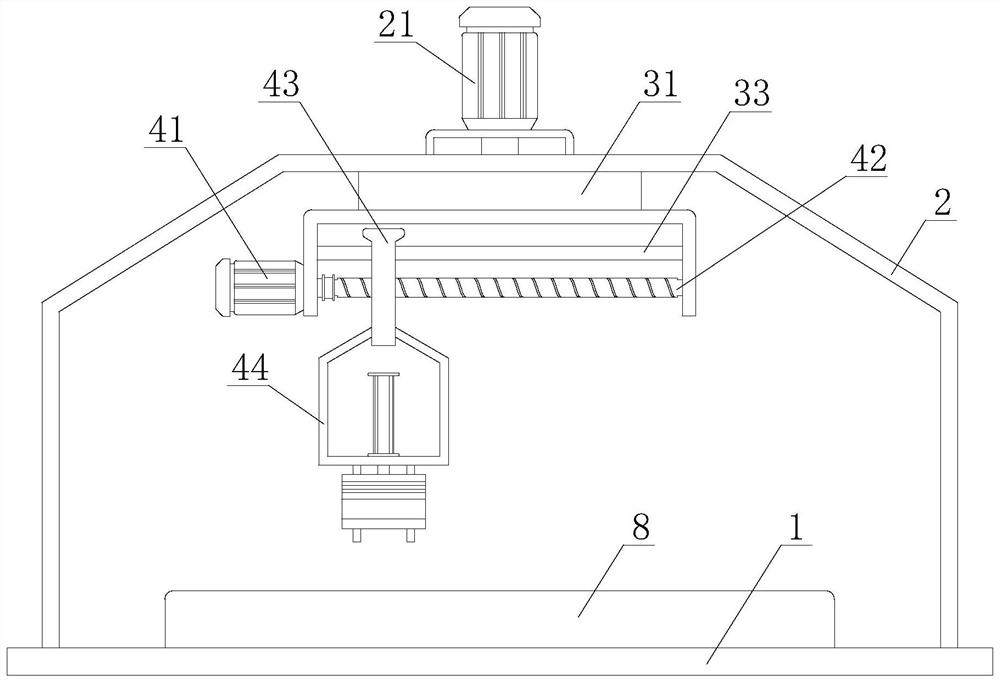

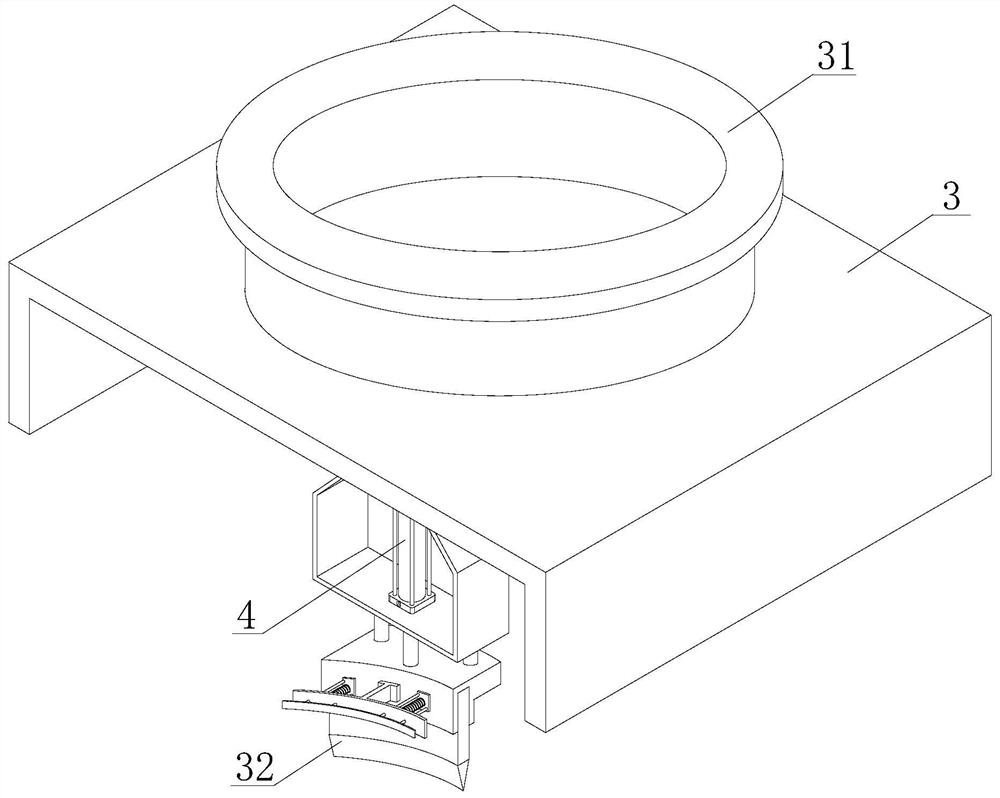

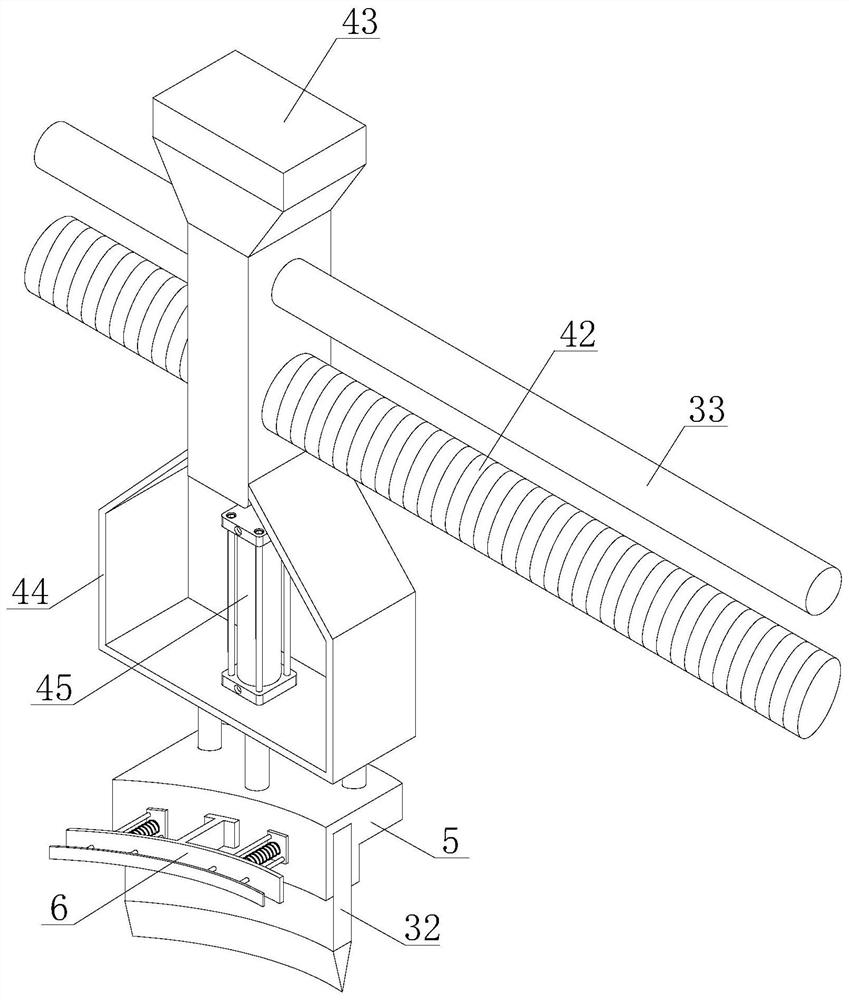

[0032] In order to better demonstrate the implementation process of the arc trimming device for stainless steel manhole cover production, this embodiment now proposes an implementation method for the arc trimming device for stainless steel manhole cover production, including the following steps:

[0033]S10: Place the stainless steel manhole cover 8 on the console 1, start the second drive motor 41 and drive the screw rod 42 to rotate, and the screw rod 42 can drive the slider 43 to translate under the guidance of the guide column 33 during the rotation process. The translation of block 43 can make connecting frame 44 and edge trimming knife 32 also translate thereupon, until edge trimming knife 32 moves to a suitable edge trimming position;

[0034] S20: the first driving motor 21 starts and drives the rotating frame 3 to rotate under the guidance of the annular guide seat 31, and the rotation of the rotating frame 3 can make the edge trimming knife 32 also rotate accordingly;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com