Efficient precision machine tool with waste liquid capable of being recycled

A precision machine tool and waste liquid recovery technology, which is applied in the direction of filtration circuit, filtration separation, grinding/polishing equipment, etc., can solve the problems of low efficiency of cutting fluid recovery and reuse, and achieve the effect of providing convenience and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

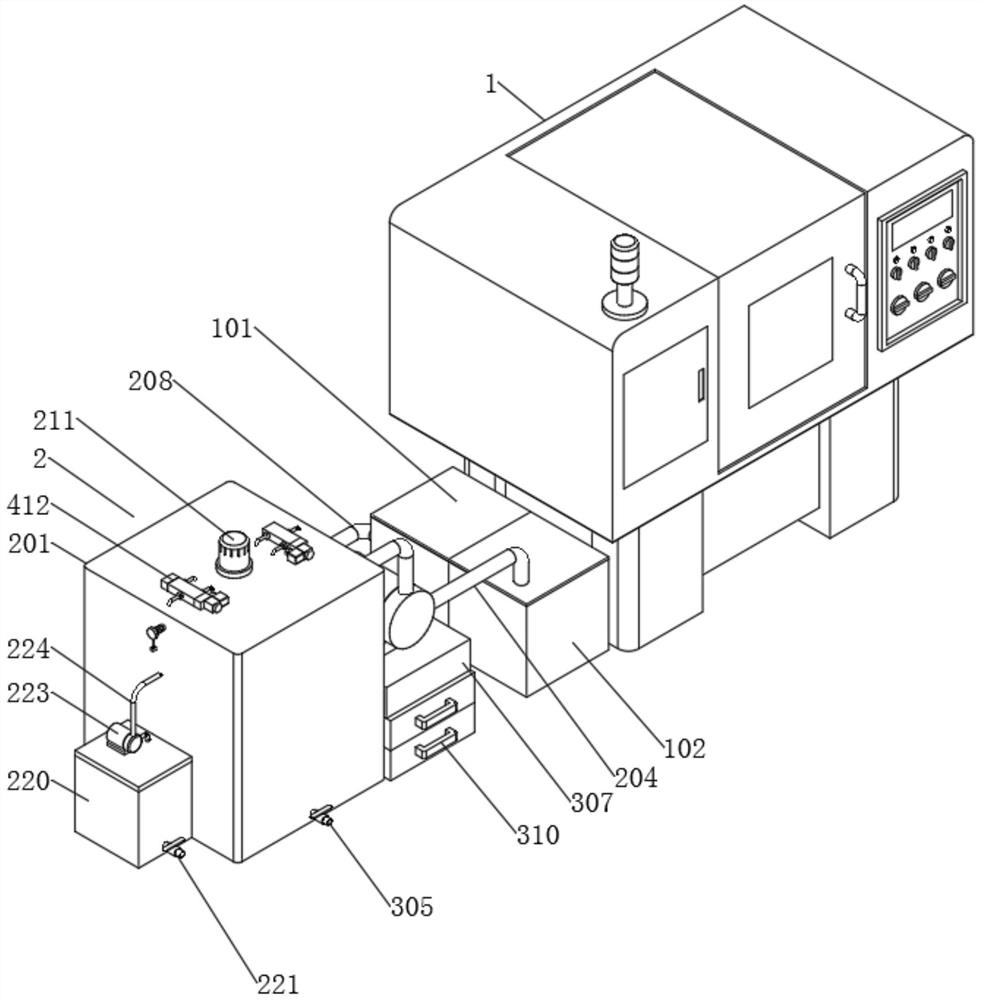

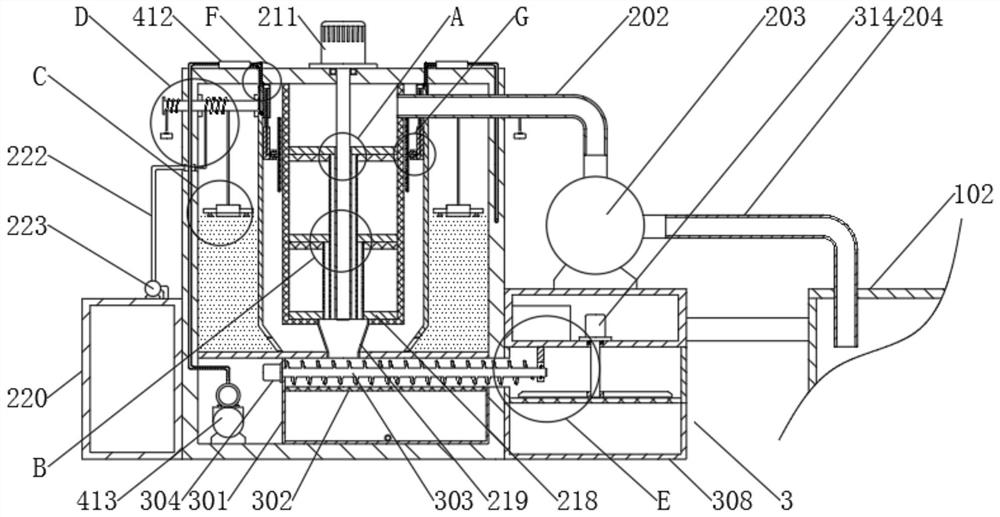

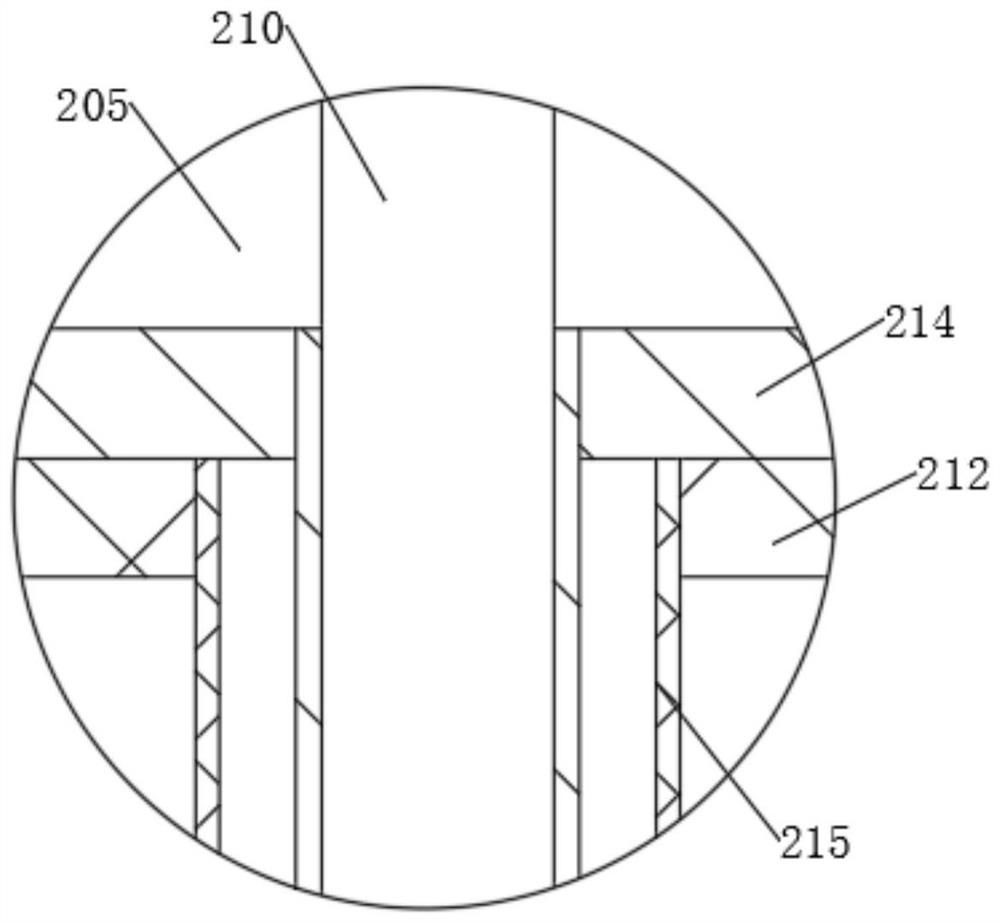

[0033] The invention discloses a high-efficiency precision machine tool for recycling waste liquid. Figure 1-Figure 9 As shown, the grinding machine body 1 is included, and one side of the grinding machine body 1 is connected with a cutting fluid storage tank 101, and one side of the cutting fluid storage tank 101 is provided with a waste liquid tank 102, and the side of the waste liquid tank 102 away from the grinding machine body 1 is provided with The multi-stage cutting fluid removal mechanism 2, the multi-stage cutting fluid removal mechanism 2 includes a waste liquid treatment box 201, by setting the waste liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com