Preparation mold of narrow-frame double-sided adhesive tape product

A double-sided adhesive and product technology, which is applied in metal processing and other directions, can solve the problems that the release film cannot be completely removed, the protective film cannot be too viscous, and the product is dirty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

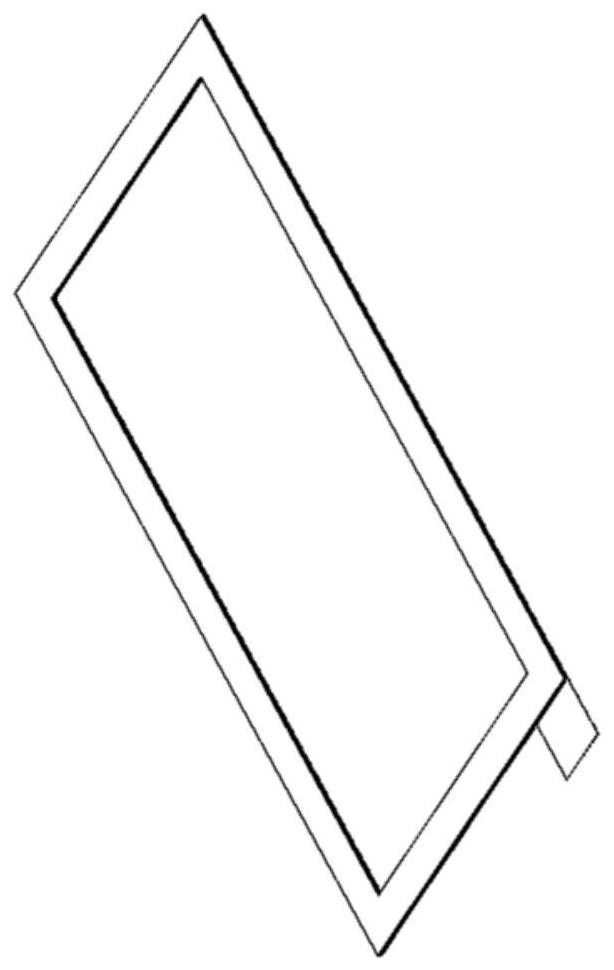

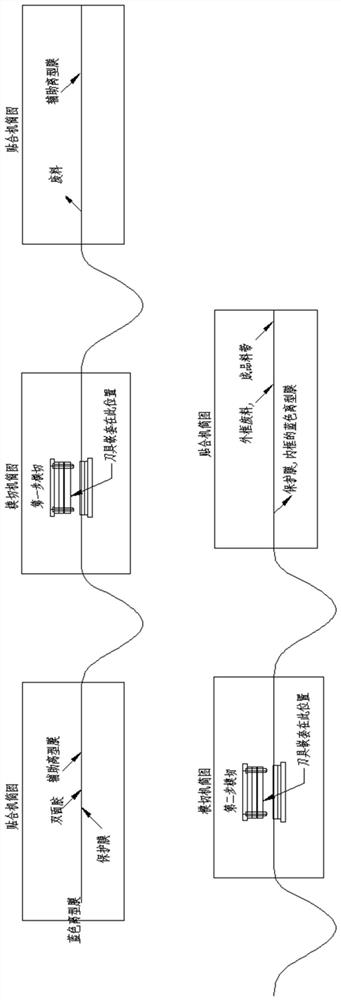

[0026] The preparation mold of the narrow-frame double-sided adhesive product in the present invention comprises the first cutting die 1 and the second cutting die 2 arranged in sequence according to the direction of the die-cutting line, see Figure 4 .

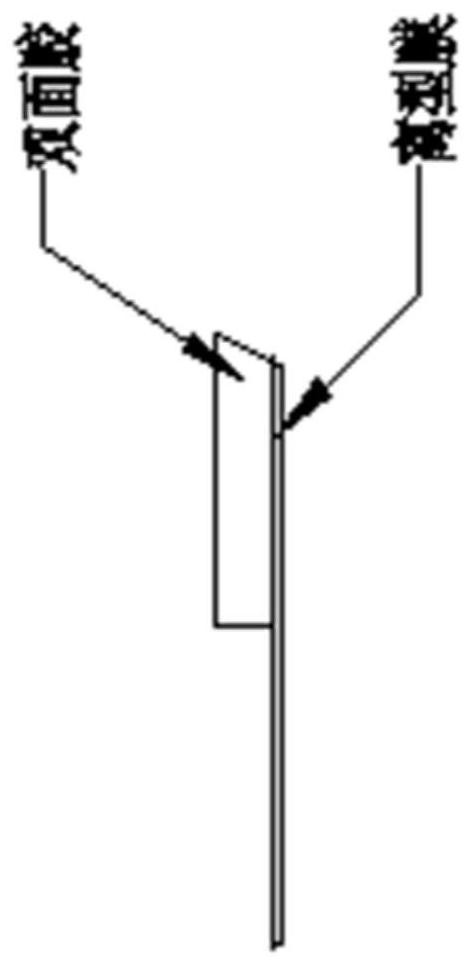

[0027] Part of the first mold 1 : including the first mold panel 11 and the protruding inner ring blade 12 provided on the first mold panel 11 .

[0028] Part of the second mold 2: including a second mold panel 21 and a raised outer ring blade 22 provided on the second mold panel 21, and a raised pressing area 23 is provided inside the outer ring blade 22. The first knife mold panel 11 and the second knife mold panel 21 are also provided with the fixing hole 3 of the mould, see Figure 4 . Both the inner ring blade 12 and the outer ring blade 22 form a closed geometric figure. The area enclosed by the outer ring blade 22 is larger than the area enclosed by the inner ring blade 12 . That is, the peripheral contour of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com