Special stable supporting base for planing machine

A technology of stable support and planer, applied in the direction of manufacturing flat surface processing machines, wood processing appliances, manufacturing tools, etc., can solve the problems of manpower consumption, easy deviation, need for manual regular inspection, and reduced work efficiency, so as to reduce labor Easy operation, fast compression connection, not easy to shift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

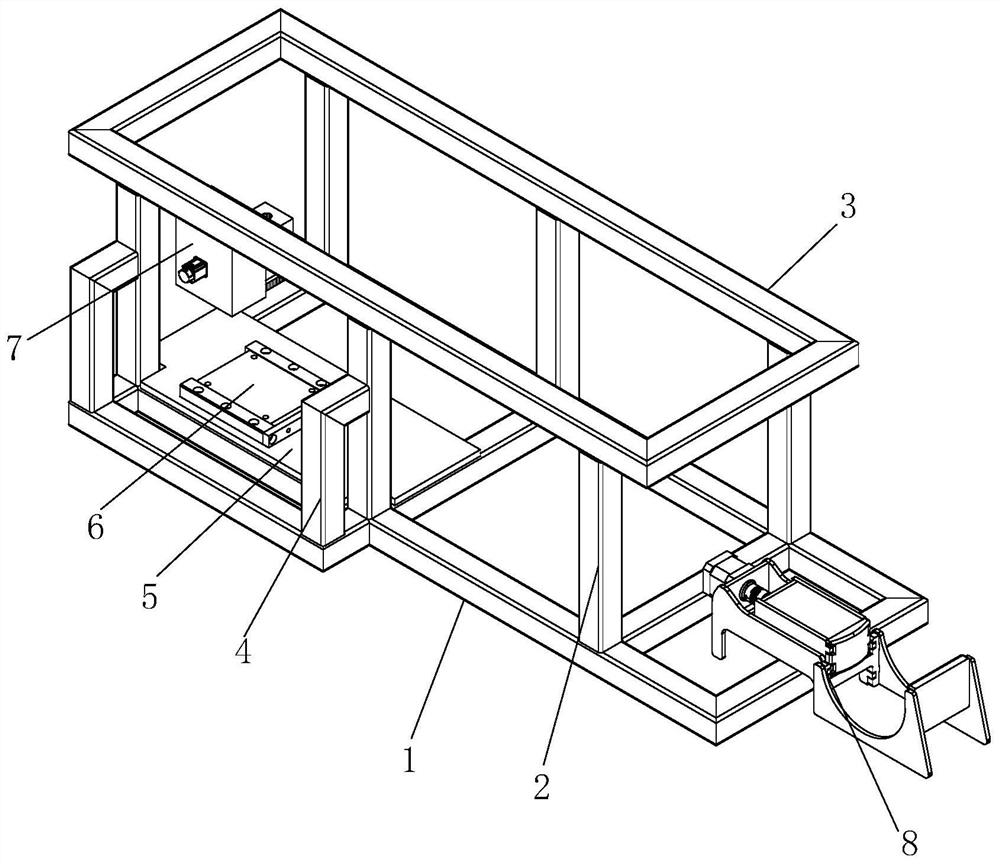

[0033] see figure 1 , the present invention provides a special stable support base for a planer through improvement, including a base 1, the four ends of the top of the base 1 are vertically fixed with a support arm 2, the top of the support arm 2 is welded to the installation frame 3, and the left end of the front end of the base 1 is The side frame 4 is fixed, the inner left end of the base 1 is welded with a fixed plate 5, the middle part of the top of the fixed plate 5 is fixed with a motor mounting seat 6 by bolts, the left front end of the bottom of the mounting frame 3 is provided with a lubricating device 7, and the top right end of the base 1 is provided with a connecting mechanism 8.

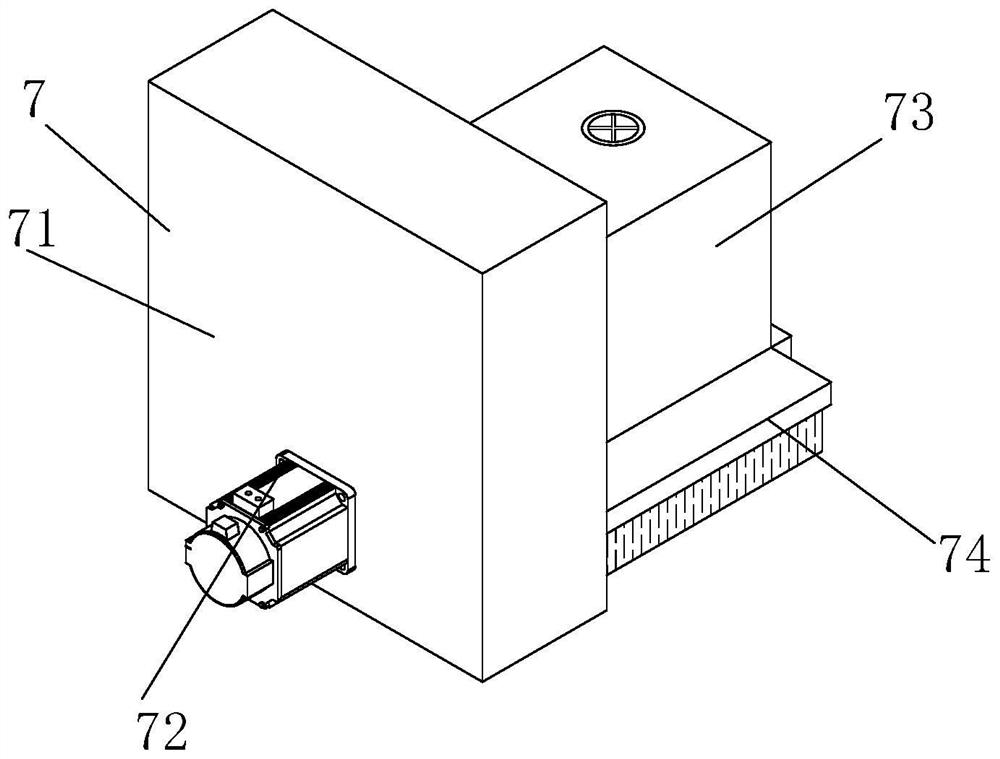

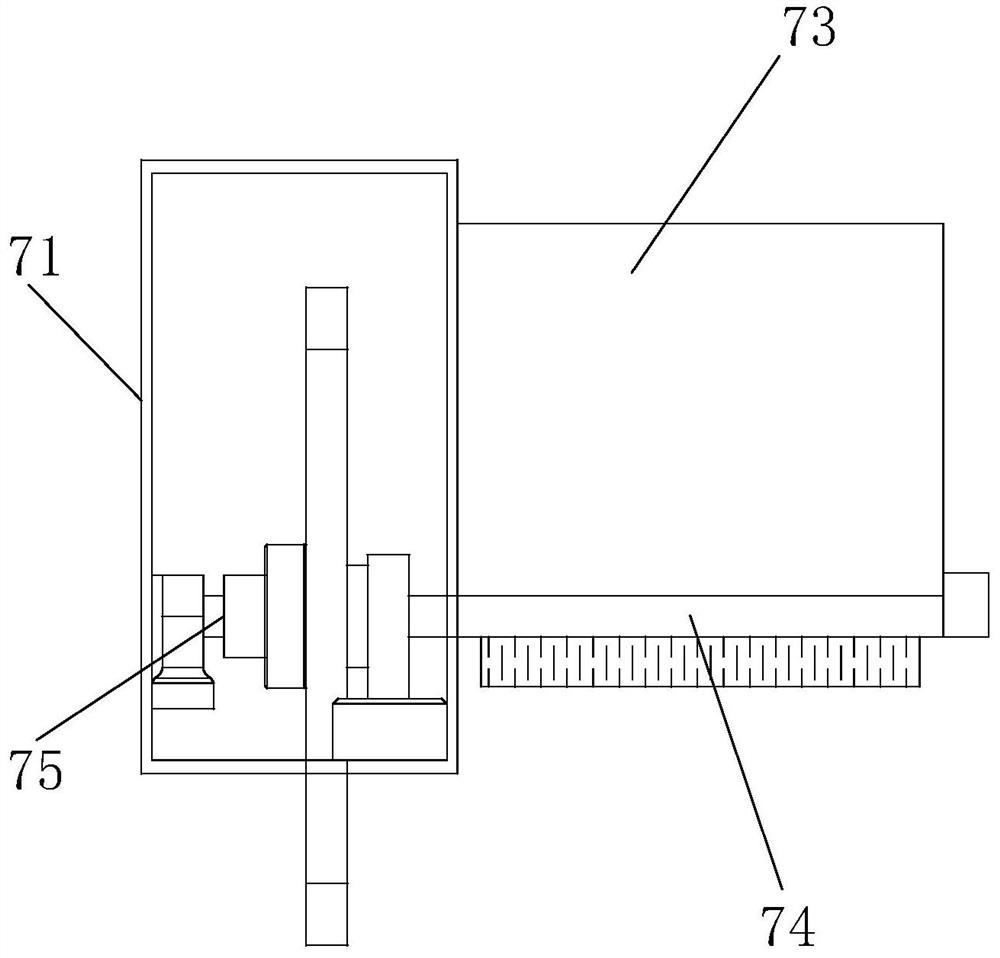

[0034] see figure 2 and image 3 , the present invention provides a special stable support base for a planer through improvement, the lubricating device 7 includes a transmission box 71, a first motor 72, an oil tank 73, an oil outlet mechanism 74 and a transmission mechanism 75, th...

Embodiment 2

[0040] The present invention provides a special stable support base for planers through improvement. The middle part of the bottom end of the transmission box 71 is open, and the bottom of the linkage 754 protrudes from the bottom opening of the transmission box 71 to facilitate the stable transmission of the linkage 754; There is a square groove on the back of 741, and the front end of the guide 733 is movably embedded in the square groove on the back of the plate body 741, which facilitates the stable sliding of the plate body 741; Sealing; both the pressure plate 86 and the inner side of the bracket 88 are bonded with a layer of silica gel, which is convenient to provide a stable buffer effect after clamping, and has a large friction force.

[0041] The present invention provides a special stable support base for a planer through improvement, and its working principle is as follows;

[0042] First, when the base needs to be used, first place the base at the position where i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap