Wooden door processing film covering device and film covering method

A technology for laminating device and wooden door, which can be used in wood processing utensils, metal processing, manufacturing tools, etc., and can solve problems such as cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Through 10 times of film coating processing and conveying tests on wooden doors, it can be concluded that its cutting component 3 can reduce the excess area of the film on both sides of the wooden door to 0.3mm after cutting, while the general after 10 times of film coating processing The remaining redundant area of artificial cutting is 1 mm, and it is more smooth after being cut by the slitting assembly 3 .

[0067] working principle:

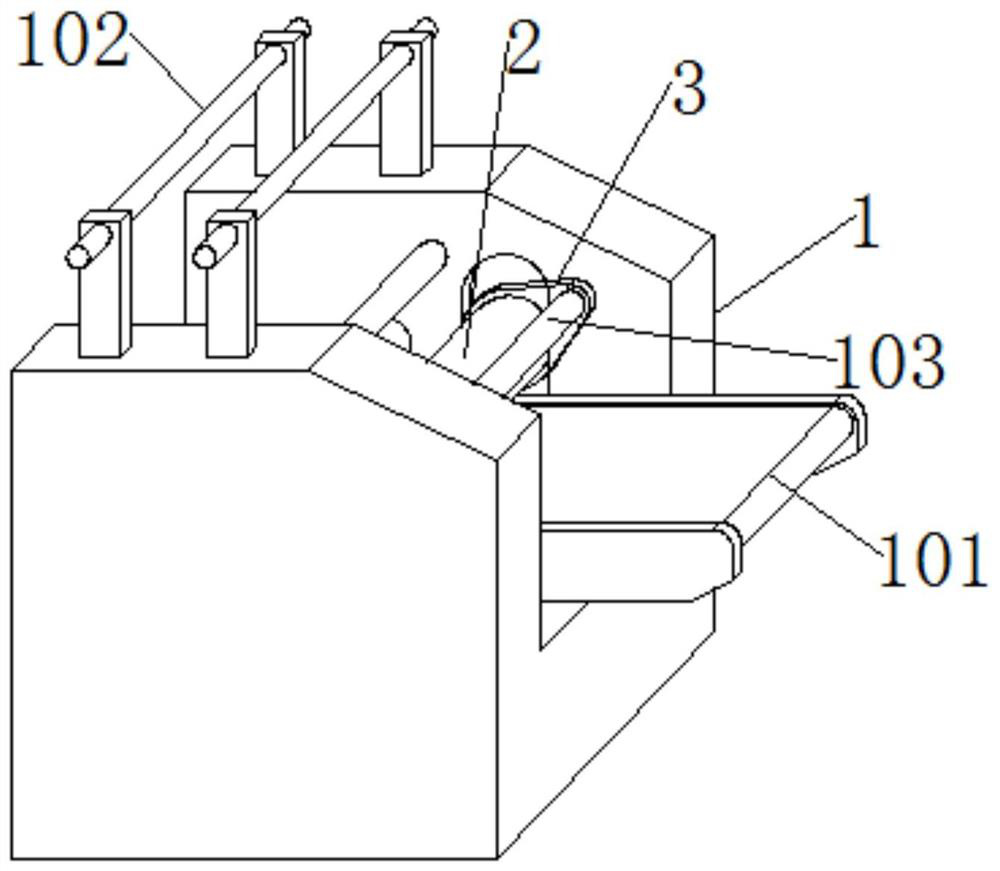

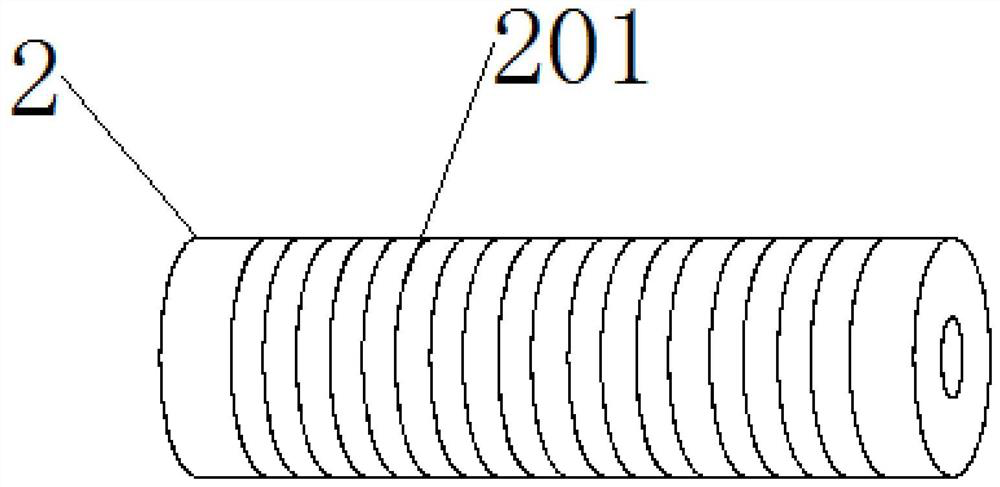

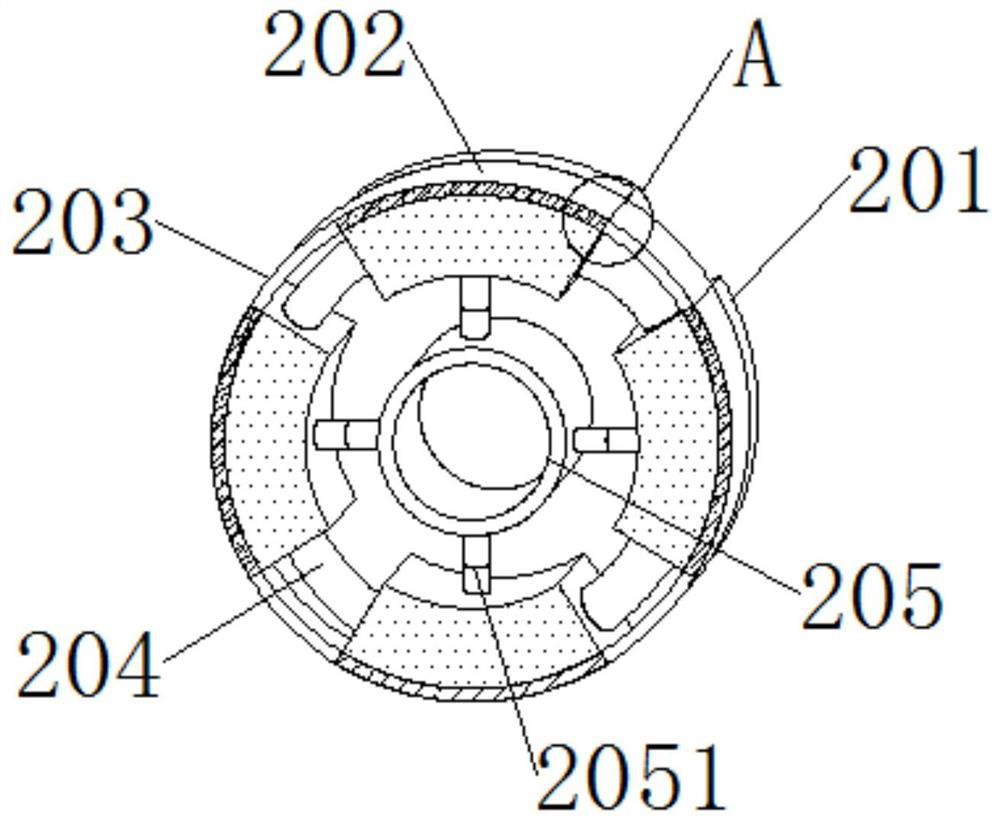

[0068] The specific use and function of this embodiment, first place the wooden door on the conveyor belt 101 of the main body 1, and place one end of it on the bottom end of the conveyor roller 2, and then put the film on one end through the transmission of the output roller 103. Attach to one end of the wooden door, and then drive the wooden door to move on the conveyor belt 101 through the rotation of the conveying roller 2 to pull the film to fit the entire wooden door surface, and when the wooden door moves through the bottom ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap