In-orbit operation labor-saving device for load supporting frame in space station cabin

A technology for supporting frame and space station, applied in the field of manned space engineering space station system, can solve the problems of insufficient on-orbit operation force of astronauts, and achieve the effect of compact structure, small transportation occupancy resources, and solving on-orbit disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

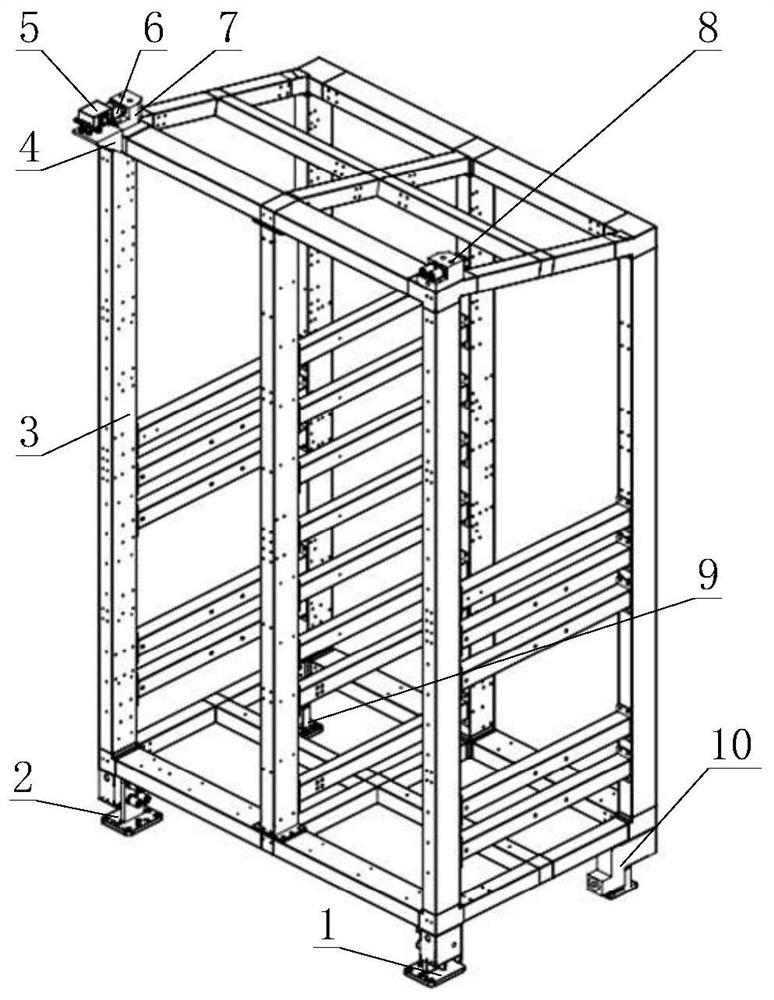

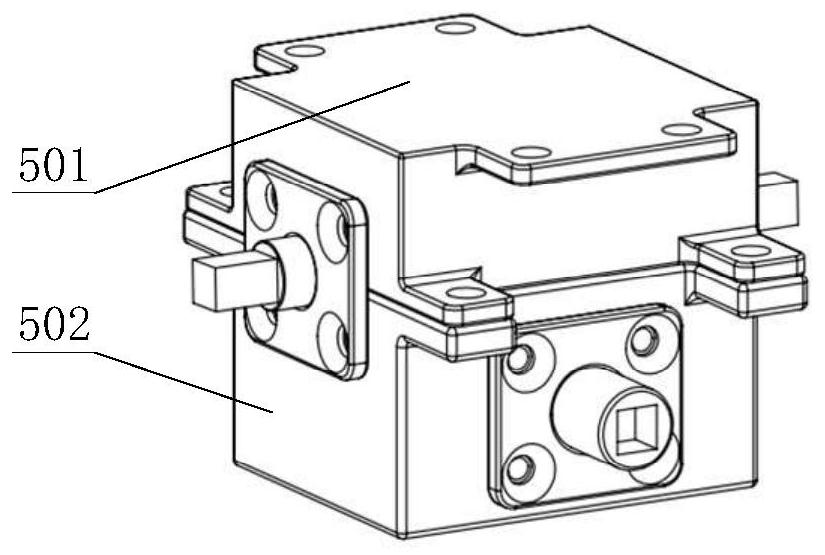

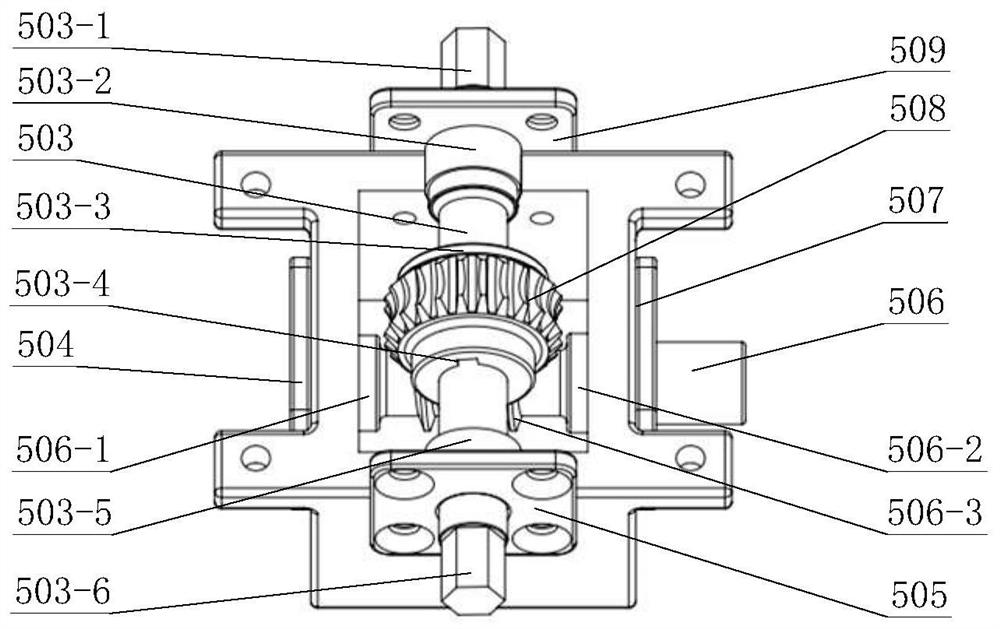

[0045] Such as Figure 4 As shown, the fixed adapter includes an upper fixed adapter 4 with a triangular structure, the upper fixed adapter 4 is installed and fixed on the upper left corner of the load support frame 3 in the cabin, and the fixing seat 501 is fixed on the upper fixed adapter 4 , realize the fixation of the labor-saving mechanism 5 and provide it with reaction support torque, at this time, the left wrench head 503-1 cooperates with the first screw 601 that does not come out; connect the head of the standard torque wrench with the input end of the worm shaft 506 and apply the active force Make it rotate counterclockwise, the worm shaft 506 and the worm wheel 508 mesh and transmit the rotational movement and torque to the left wrench head 503-1, and the left wrench head 503-1 rotates clockwise and drives the first non-extracting screw 601 matched with it to rotate together , the first non-protruding screw 601 makes the installation point of the load support frame ...

Embodiment 2

[0047] Such as Figure 5 As shown, the upper fixing adapter 4 moves horizontally for a certain distance to the right and is fixed with the reserved interface of the load support frame 3 in the cabin. , so that the left wrench head 503-1 cooperates with the second non-detachable screw 602; repeating the steps in the first embodiment can realize the tightening or loosening of the second non-detachable screw 602;

Embodiment 3

[0049] Such as Figure 6 As shown, the fixed adapter also includes a first lower fixed adapter 11, the first lower fixed adapter 11 is fixed at the left front lower corner of the load support frame 3 in the cabin, and the labor-saving mechanism 5 is fixed on the first lower Fix the adapter 11 and provide the reaction supporting moment for the labor-saving mechanism 5. At this time, the right wrench head 503-6 cooperates with the third non-prolapse screw 601; the third non-prolapse screw 601 makes the cabin The installation point of the internal load support frame 3 is tightened with the standard interface in the cabin of the space station; similar to the steps in the first embodiment, the head of the standard torque wrench is connected to the input end of the worm shaft 506 and the active force is applied to make it reverse. Clockwise or clockwise rotation can realize the tightening or loosening of the third non-extraction screw 603 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com