An automatic access system for double-layer storage roller table for heavy-duty products

A technology of automatic access and roller table, which is applied in the direction of roller table, storage device, transportation and packaging, etc., can solve the problems of low space utilization rate, increase of warehouse area, high storage cost, etc., and achieve high space utilization rate and low storage cost , the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

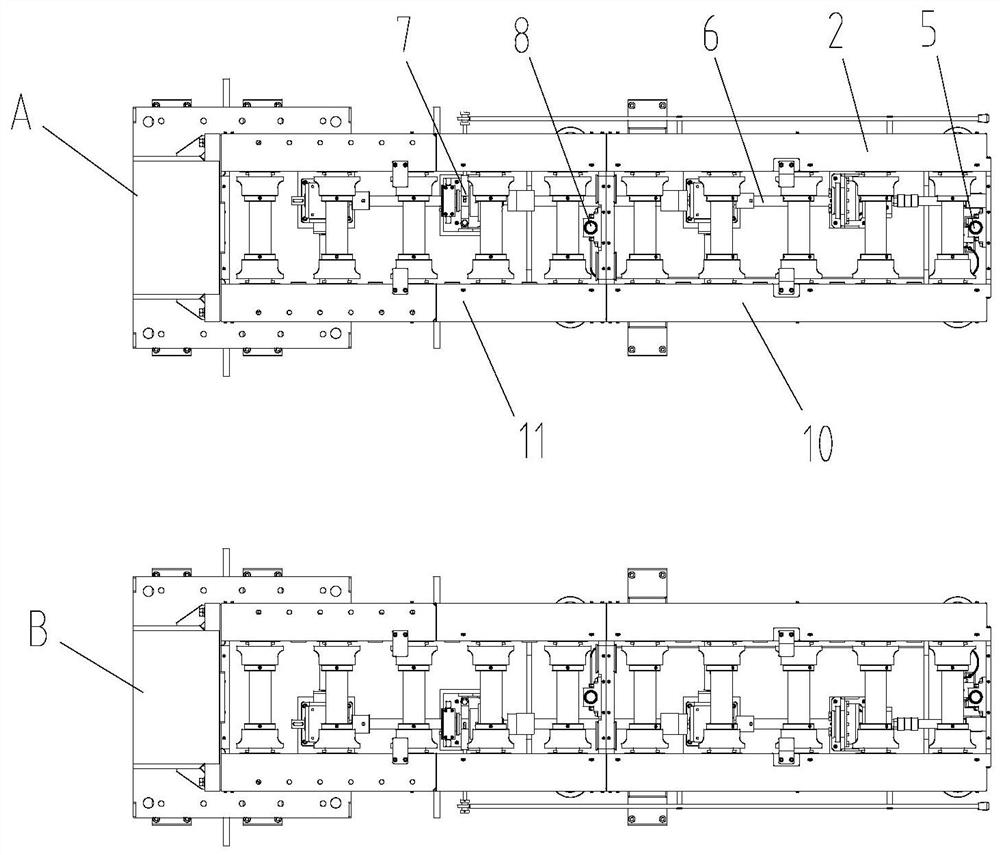

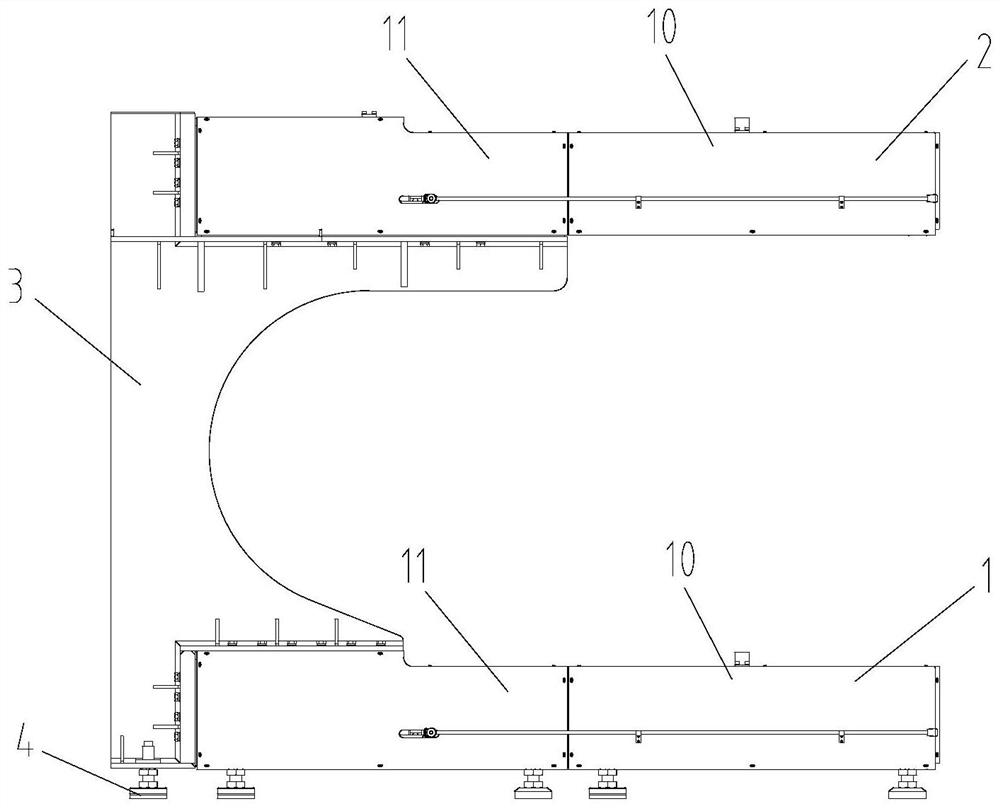

[0032] like Figure 1-2 As shown, the present invention provides an automatic access system for double-layer storage rollers for heavy-duty products, including supporting roller table IA and supporting roller table IIB for supporting both ends of heavy-duty products, supporting roller table IA The structure is the same as that of the supporting roller bed IIB, and both include a lower storage roller table 1 and an upper storage roller table 2, and the lower storage roller table 1 and the upper storage roller table 2 are detachably connected by a support column 3.

[0033] The lower storage roller table 1 and the upper storage roller table 2 have the same structure, both including the storage roller table I10 and the storage roller table II11, wherein one end of the storage roller table II11 is connected to the support column 3, and the other end is detachably connected to the storage roller table I10. The storage roller table I10 and the storage roller table II11 are driven to...

Embodiment 2

[0043] When the width space is satisfied but the height space is not satisfied, the upper storage roller table 2 of the support roller table IA and the support roller table IIB can be removed, and only the lower storage roller table 1 is kept, such as Figure 7-8 shown.

Embodiment 3

[0045] When the width space is not satisfied and the height space is satisfied, the storage roller table I10 of the upper storage roller table 2 and the lower storage roller table 1 in the support roller table base IA can be removed, and only the storage roller table II11 is reserved. Similarly, remove the storage roller table I10 of the upper storage roller table 2 and the lower storage roller table 1 in the supporting roller table seat IIB, and only keep the storage roller table II11, as Figure 9-10 shown.

[0046] The specific implementation process of the storage process of the present invention is:

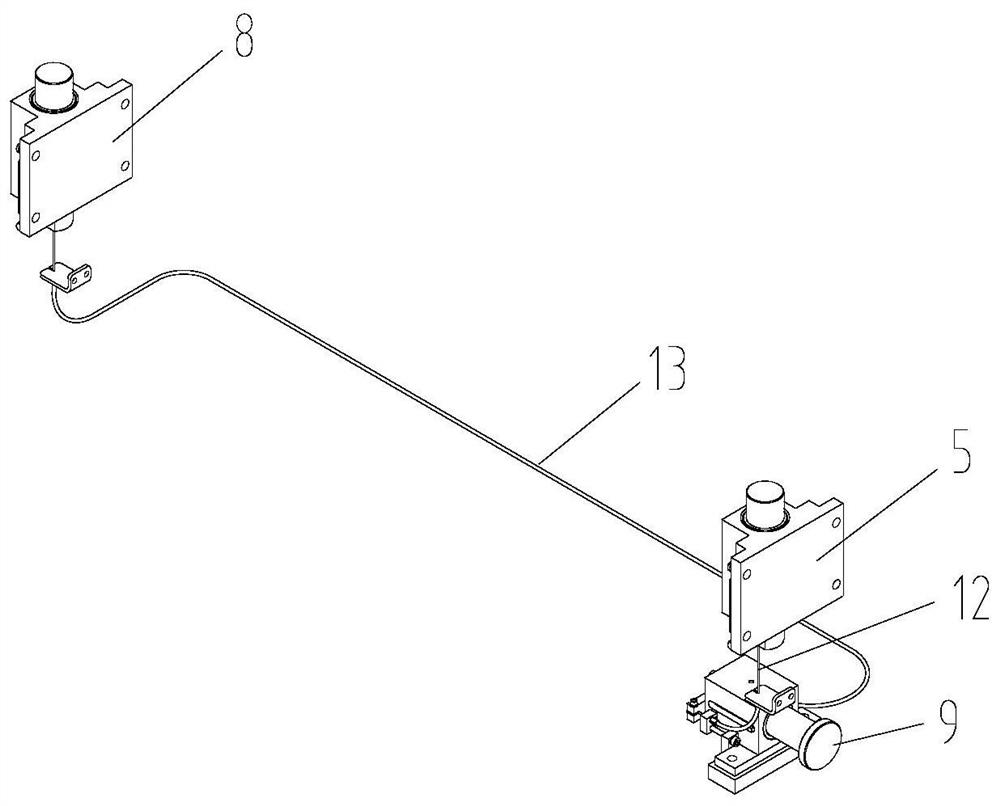

[0047]When the heavy-duty products on the outer layer of the first floor are stored, they are transported to the docking station of the storage roller by the automatic guided vehicle or other equipment. The automatic guided vehicle or other equipment stretches out the unlocking block and the docking rod, and the unlocking block pushes the unlocking lever 94 to move forward. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com