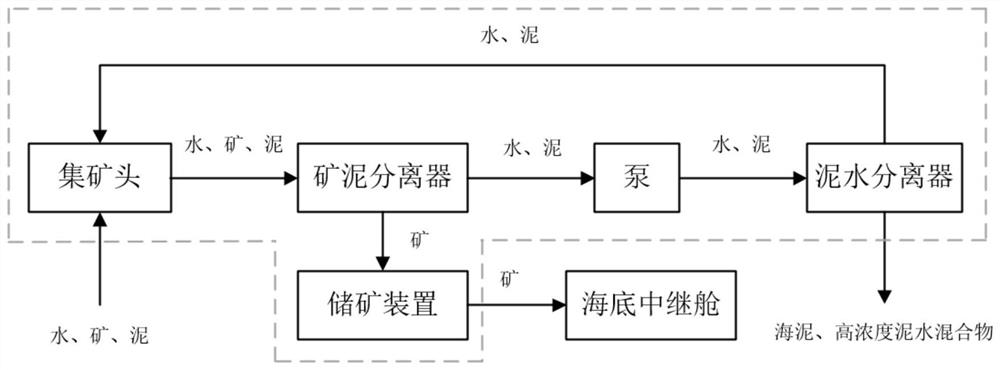

Circulating slurry-water separation system for seabed ore collection

A mud-water separation and circulation technology, which is applied in the fields of fluid machinery and ocean engineering, can solve the problems that water flow energy cannot be recycled, the disturbance of the seabed ecological environment is large, and the separation rate of ore particles and sea mud is low, so that the reliability is guaranteed and the use Long life and sufficient separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

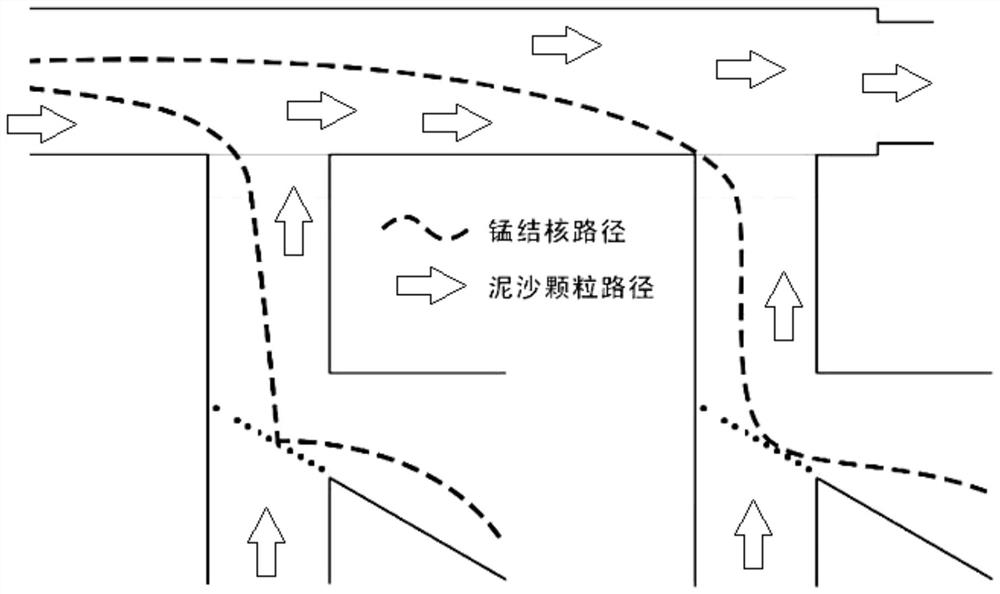

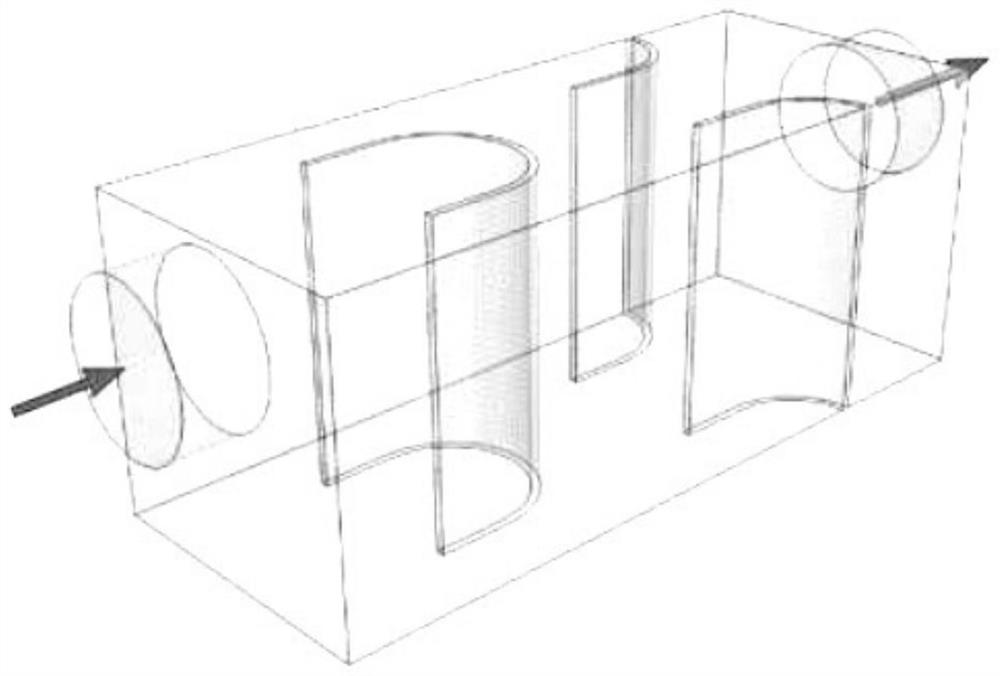

[0034] In this example, based on the difference in motion characteristics of manganese nodules and sea mud particles, a design scheme of gravity sludge separator with simple structure and high separation rate is proposed. Such as figure 1 As shown, the main body of the gravity slime separator is two continuous T-shaped hollow structures, which can be divided into two parts: the upper horizontal flow channel and the lower shaft. The inlet of the horizontal flow channel is the inlet of manganese nodules and mud-water mixture, which is connected to the ore collecting head through pipelines; the outlet is the outlet of mud-water mixture and connected to the pump; a row of porous baffles is set in the vertical shaft; The mine device is connected; the entrance of the vertical shaft is a low-speed water flow inlet, which is connected to the mud-water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com