Coconut fiber high-speed carding machine

A carding machine and coconut palm technology, applied in fiber processing, deburring devices, textiles and paper making, etc., can solve problems such as sticking, uneven thickness of coconut palm, and slow work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

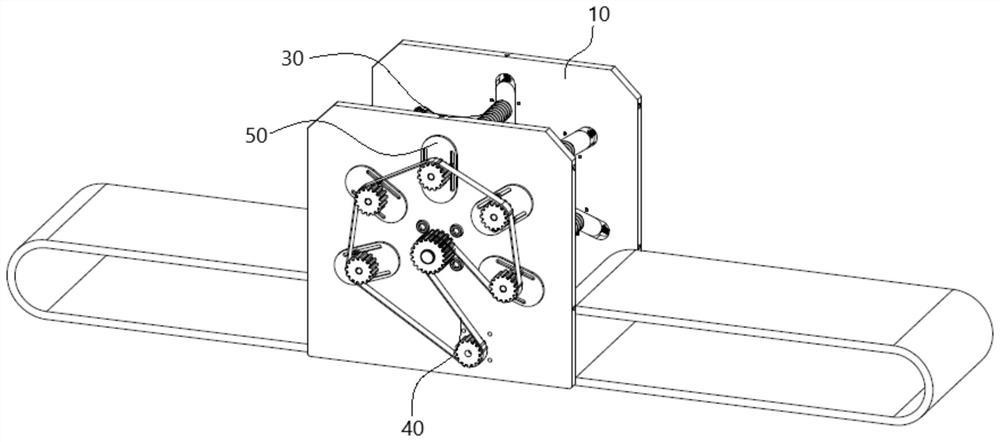

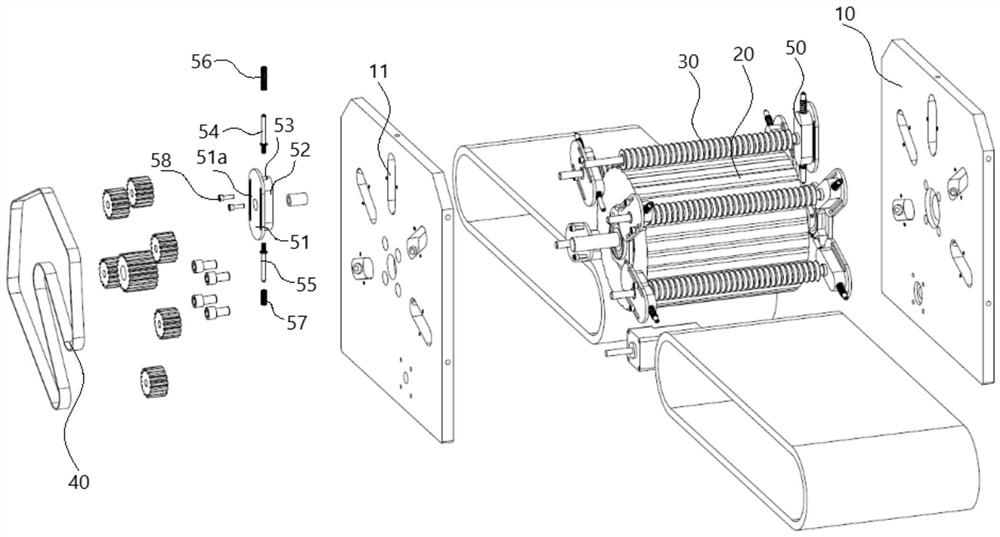

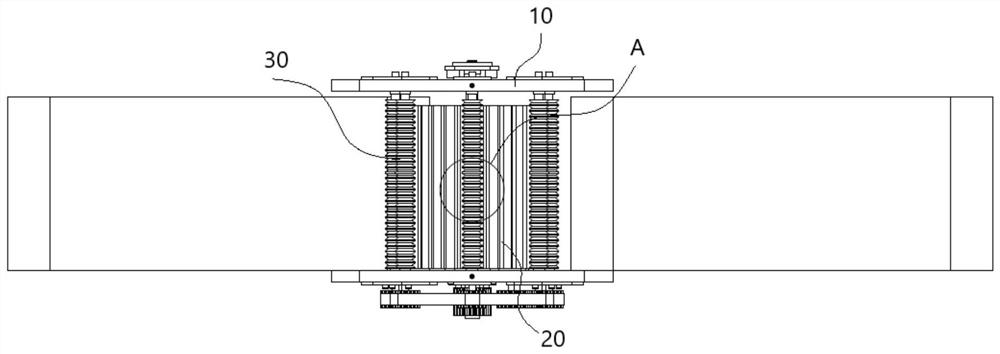

[0026] The present invention discloses a coconut brown high speed card, including a central wheel mounted on a casing and a number of combing Luolas, a central roller, and a central roller, and each comb, and each comb. High speed rotation of the casing. The two ends of the comb are mounted on the casing by elastic floating mounting assemblies, respectively, by elastic floating mounting assemblies, the spacing between rollers and central rollers is real-time; wherein the outer peripheral surface of the center roller is provided with a number of horizontal spaces. Structure, while each of the outer peripheral surfaces of each comb, there is a vertical combing teeth that are called intervals, under the drive of the belt wheel assembly, the center wheel and each comb are synchronously rotate, so that each horizontal combing teeth and vertical card The teeth are synchronously combed with coconut brown raw materials in horizontal and vertical directions, respectively.

[0027] In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com