A controllable structure heat insulation material and its preparation method

A heat insulation material and structural fiber technology, applied in textiles and papermaking, fiber treatment, non-woven fabrics, etc., can solve the problems of uneven distribution of anti-radiation agents, complex dispersion system, poor stability of dispersion system, etc., to achieve high temperature Thermal insulation performance, good thermal insulation performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

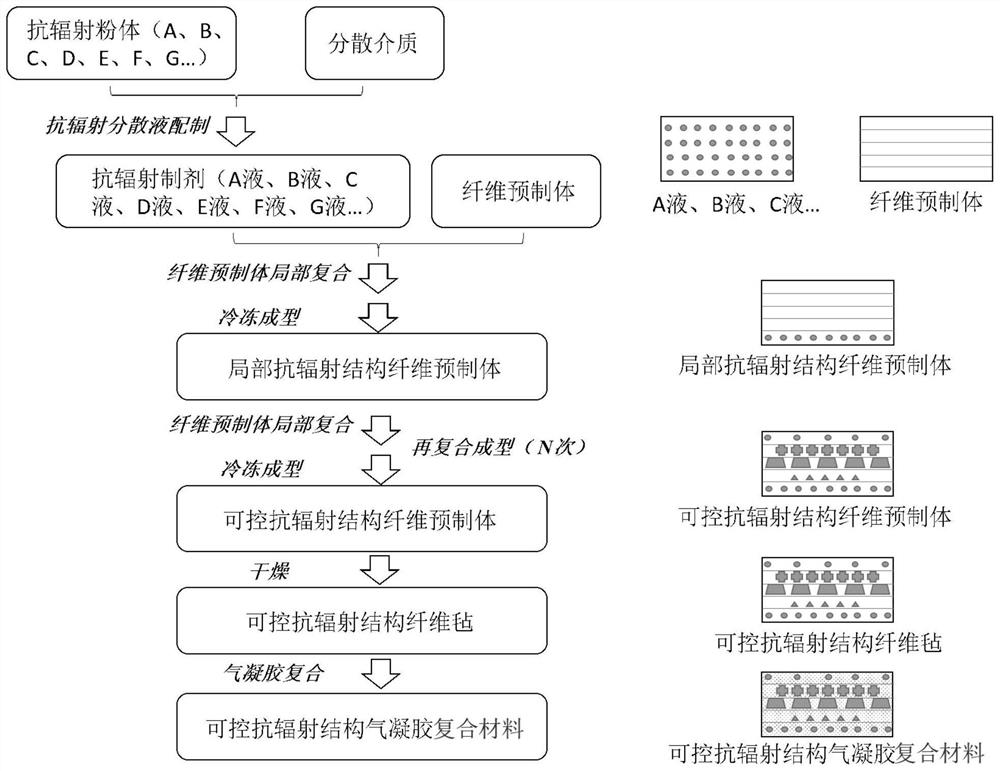

Method used

Image

Examples

Embodiment 1

[0027] The size is 500 mm× 500 mm×30 mm, and the density is 0.1 g / cm 3A piece of commercially available quartz fiber felt with a thermal conductivity of 0.12 W / (m•K) and a thermal conductivity of 0.24 W / (m•K) at 1000°C. To 600 mm×600 mm×50 mm tank (i.e., composite container) was added 37.5L of silicon carbide - tert-butanol dispersion with a solid content of 8%, the quartz felt was slowly placed into it until the dispersion was all sucked into the felt body, after 30min of rest, it was taken out and quickly frozen at 0 °C, a layer of about 15mm thick silicon carbide was formed inside the fiber felt, and then the fiber felt was placed in a tank of 600 mm × 600 mm ×50 mm, and the solid content was added to 4% The silicon carbide- tert-butanol dispersion liquid to the dispersion liquid to completely soak the remaining space of the felt, quickly frozen again at 0 °C, and then dried in vacuum to obtain radiation-resistant fiber felt, with a total weight gain of 60%, a thermal conducti...

Embodiment 2

[0029] The size is 500 mm× 500 mm×30 mm, and the density is 0.1 g / cm 3A piece of commercially available quartz fiber felt with a thermal conductivity of 0.12 W / (m•K) and a thermal conductivity of 0.24 W / (m•K) at 1000°C. To 600 mm×600 mm ×50 mm tank was added 25L silicon carbide - tert-butanol dispersion with a solid content of 6%, the quartz felt was slowly placed into it until the dispersion was all sucked into the felt body, after 30min of rest, it was taken out at 0 °C and quickly frozen, a layer of about 10mm thick silicon carbide was formed inside the fiber felt, and then 25L of silicon carbide-tert-butanol dispersion with a solid content of 2% was added to the tank with a solid content of 2% to the tank of 600 mm× × 600 mm. The uncombined side of the quartz felt is slowly placed into it until the dispersion is all sucked into the felt body, after 30min of rest, it is taken out again and quickly frozen at 0 ° C, and an anti-radiation layer of about 10 mm thick is formed at b...

Embodiment 3

[0031] The size is 500 mm× 500 mm×30 mm, and the density is 0.1 g / cm 3A piece of commercially available quartz fiber felt with a thermal conductivity of 0.12 W / (m•K) and a thermal conductivity of 0.24 W / (m•K) at 1000°C. Add 37.5L of silicon carbide-tert-butanol dispersion with a solid content of 5% to the tank of 600 mm × 600 mm ×50 mm, slowly put the quartz felt into it until the dispersion is all sucked into the felt body, take it out at 0 °C after 30 min of rest, quickly freeze it, form a layer of about 15 mm thick silicon carbide inside the fiber felt, and then place the fiber felt in a tank of 600 mm ×600 mm ×50 mm, and add a solid content of 3% Boron nitride - water dispersion liquid to dispersion liquid to completely soak the remaining space of the felt, again in -20 °C rapid freezing, and then dried in vacuum, to obtain radiation-resistant fiber felt, the total weight gain of 42%, 600 °C thermal conductivity of 0.057 W / (m • K), 1000 °C thermal conductivity of 0.1 W / (m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com