Valve assembly and scroll compressor comprising same

A scroll compressor and valve assembly technology, applied in the field of compressors, can solve problems such as poor reliability and complex capacity adjustment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

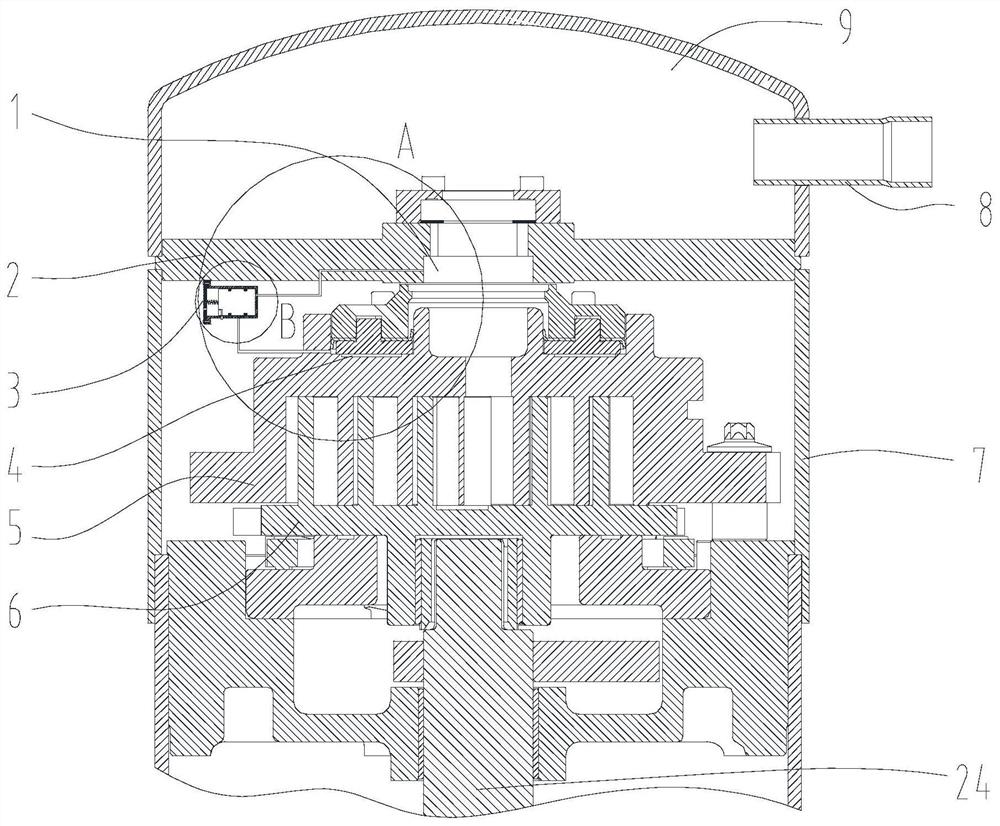

[0051] like figure 1 As shown, the present invention provides a scroll compressor. The scroll compressor is mainly composed of a partition plate 2, a static disk 5, a moving disk 6, a housing 7, an exhaust pipe 8, and a crankshaft 24. There is an exhaust chamber 9 between the plate 2 and the housing 7 , the exhaust port 1 of the static disc communicates with the exhaust chamber 9 , and the exhaust pipe 8 is installed on the housing 7 and communicates with the exhaust chamber 9 . The crankshaft 24 is connected to the moving disk 6 through transmission, which can drive the rotating disk 6 to rotate; between the static disk 5 and the housing 7 is an air suction chamber 25; Rotating and translating to form a series of crescent-shaped compression chambers 4 between the two to realize the compression process of the gaseous refrigerant.

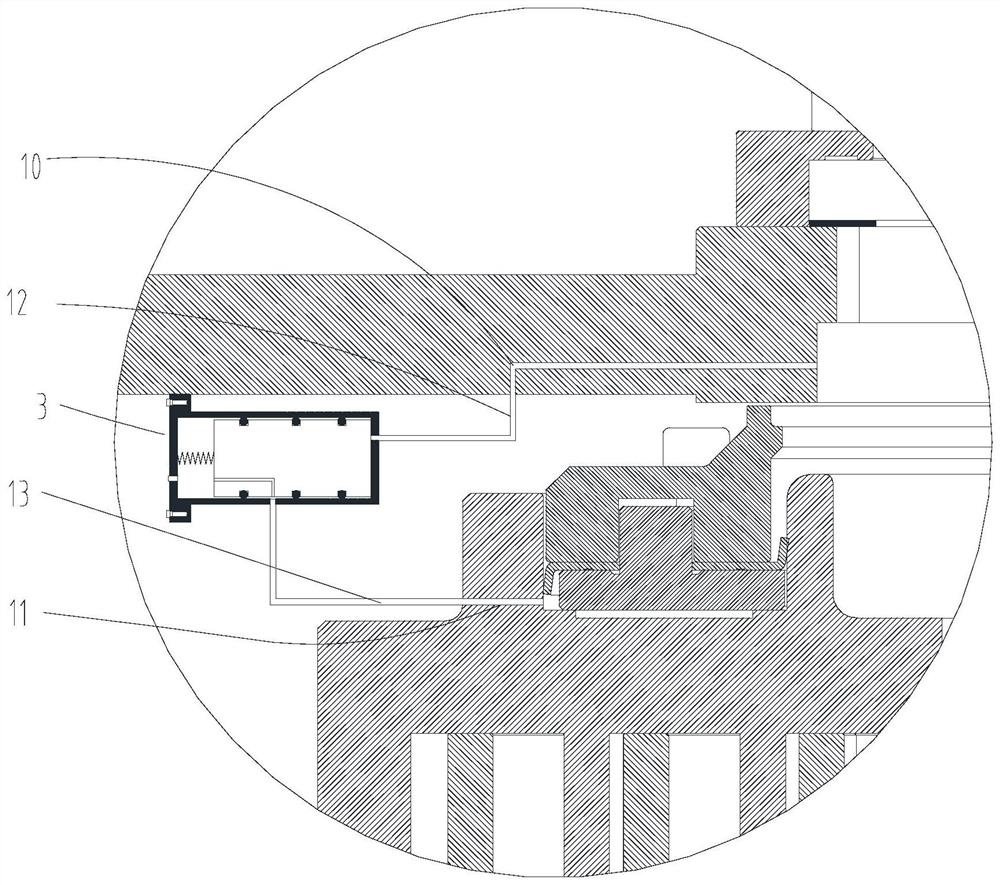

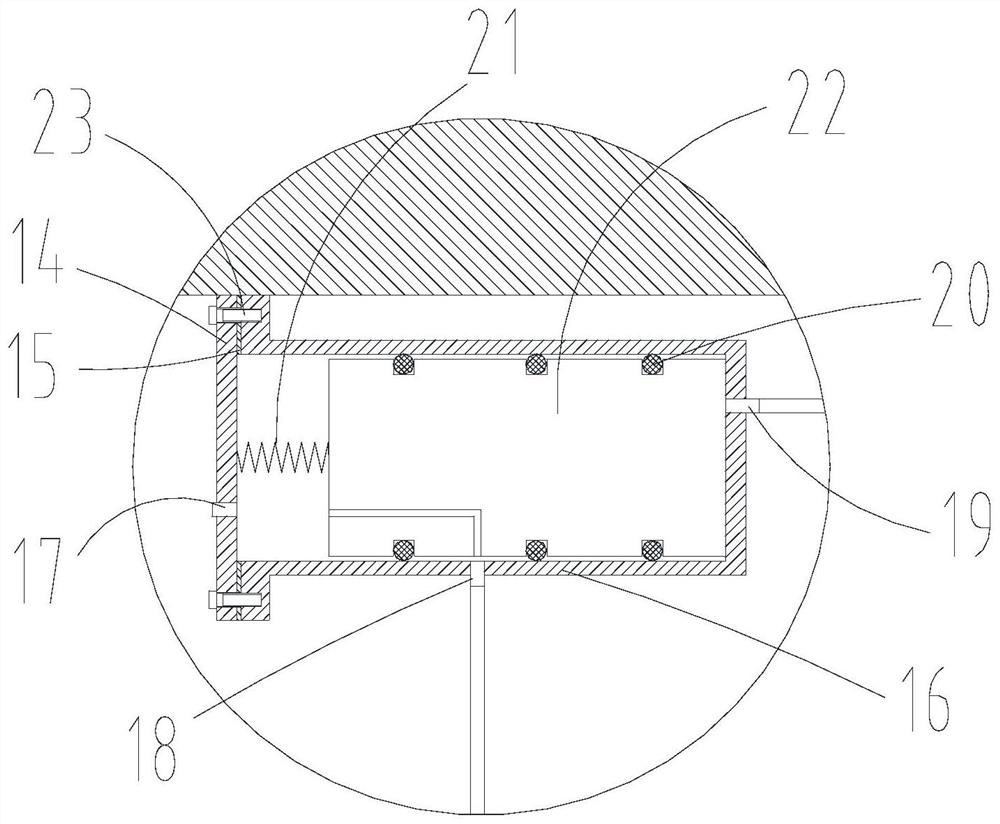

[0052] It also includes a valve assembly 3 arranged in the scroll compressor, such as Figure 1-Figure 3 As shown, the valve assembly 3 is assemb...

Embodiment 2

[0057] like Figure 13 As shown, in this embodiment, only the differences from Embodiment 1 are described, and the difference between Embodiment 2 and Embodiment 1 is that the introduction end of the exhaust channel 10 is not the exhaust port 1 of the static disk, but the exhaust Cavity 9. In this embodiment, the exhaust channel 10 is arranged vertically through the partition plate 2 , the top end communicates with the exhaust chamber 9 , and the lower end connects with the exhaust hose 12 . In the second embodiment, the exhaust refrigerant in the exhaust chamber 9 is led to the pressure discharge chamber of the valve assembly 3, and the drive for changing the position of the valve core is realized under partial load.

[0058] It should first be explained here that "inward" refers to a direction toward the center of the accommodating space, and "outward" refers to a direction away from the center of the accommodating space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com