A radiant tube burner that can roll smoke to achieve flameless combustion

A radiant tube and burner technology, applied in the field of radiant tube burners, can solve the problems of limited and unreachable maximum flue gas return flow, and reduced air supply to the radiant tube, so as to avoid long-term shutdowns, save use costs, and avoid Fragile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

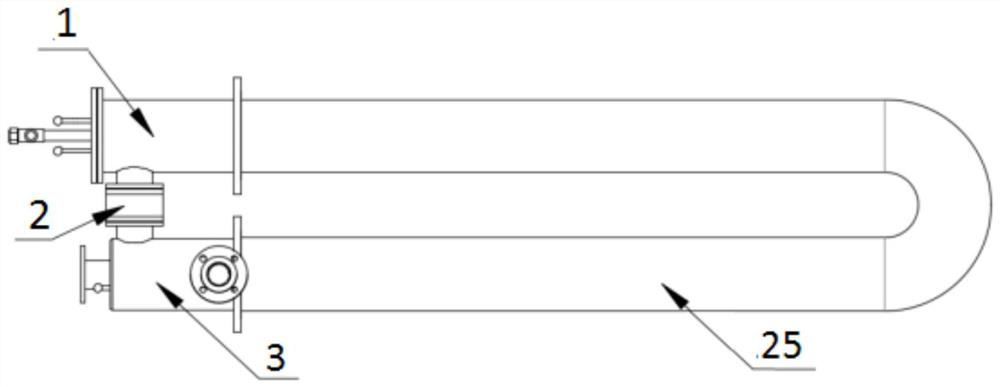

[0035] Embodiment 1: The present invention provides a radiant tube burner that can roll smoke to achieve flameless combustion. The structure of the burner when used together with the radiant tube is as follows: figure 1 As shown, the burner 1 is installed at the inlet end of the radiant tube 25, and the heat exchanger 3 is installed at the outlet end of the radiant tube.

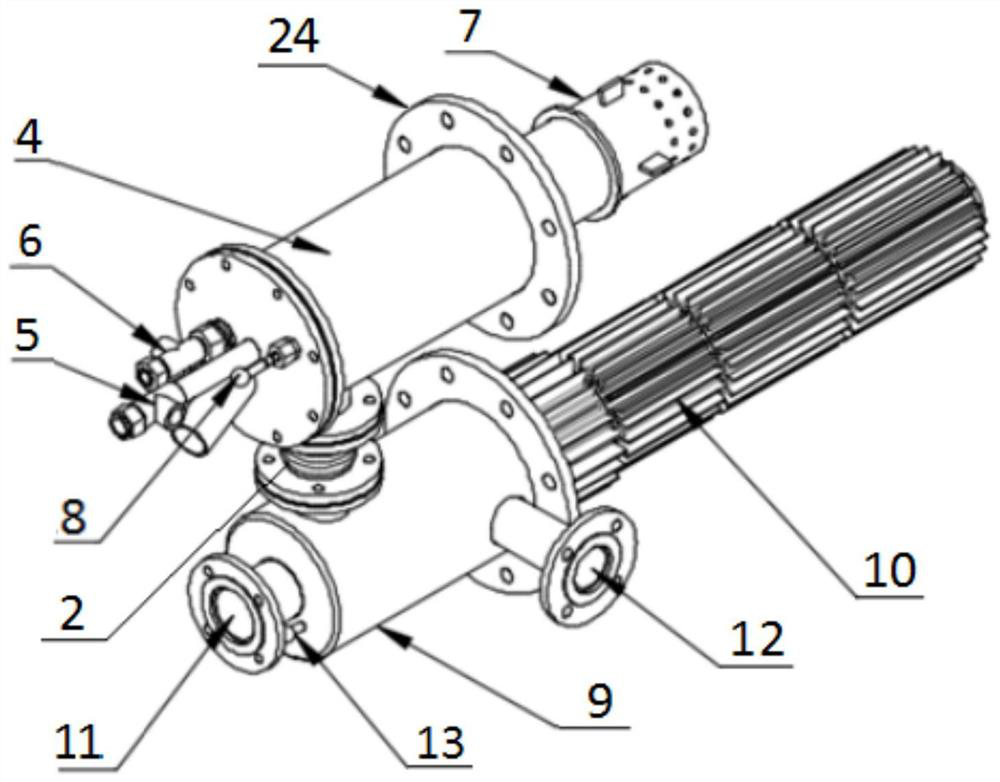

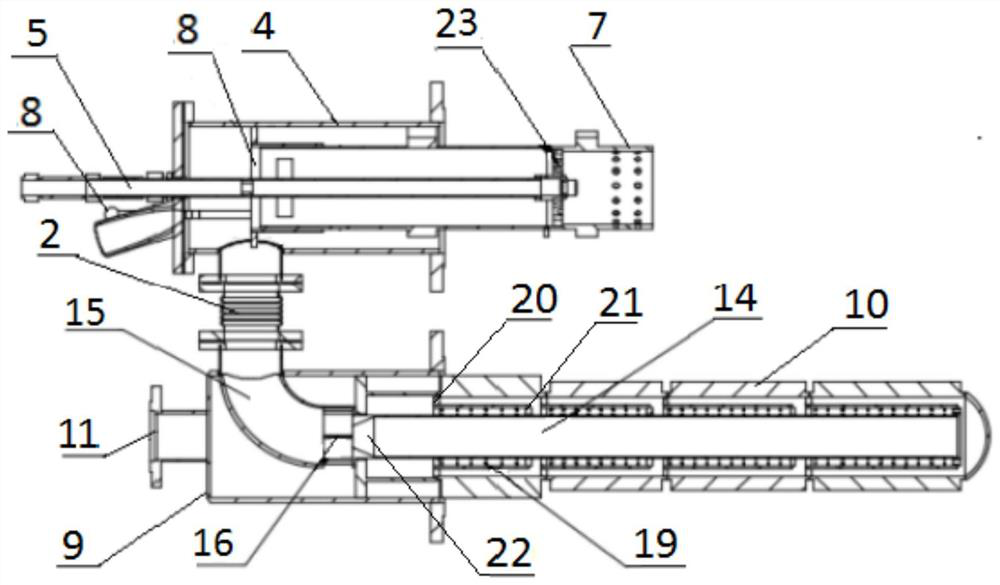

[0036] For the external overall structure and internal structure of the radiant tube burner of the present invention, please refer to figure 2 , 3 , the burner is provided with a burner 1, a mixer 2 with an expansion joint returning flue gas and combustion-supporting air, and a heat exchanger 3, the burner is provided with a burner shell 4, and the gas enters the burner shell through a gas pipe 5, The end of the gas pipe is provided with an air distribution plate 23 and a gas nozzle; the burner is connected to the radiant pipe 25 through a connecting flange 24 .

[0037] One end of the burner shell is ins...

Embodiment 2

[0043] Embodiment 2: The present invention provides a radiant tube burner that can roll smoke to achieve flameless combustion. Its structure and working process are basically the same as those of Embodiment 1, and the difference is that the smoke return pipe 16 is sleeved. Sleeve 18, one end of the handle of the return window adjustment rod 13 is exposed outside the heat exchanger shell 9, and the other end of the return window adjustment rod is connected to the sleeve 18, see the sleeve structure Figure 8 , 9, the sleeve is a cylindrical structure, the right end of the sleeve is provided with a closed ring 181, the closed ring is provided with a channel, the sleeve and the flue gas return pipe are installed concentrically, when the handle of the return window adjustment rod 13 is pushed into the heat exchanger shell, The sleeve can be gradually opened until the return window is fully opened. When the handle is gradually pulled out of the heat exchanger shell, the sleeve can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com