Cloth drying and winding equipment

A cloth drying and equipment technology, applied in the field of textile production, can solve the problems that the appearance of cloth cannot be guaranteed, affect the efficiency of cloth winding, affect the performance of cloth, etc., and achieve the effect of improving winding efficiency, saving manpower and material resources, and preventing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

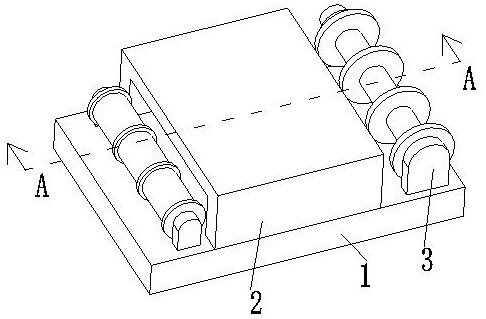

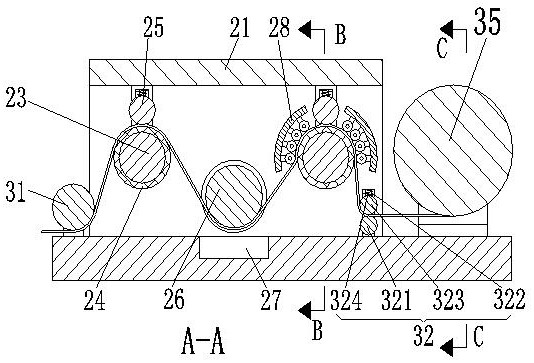

[0026] Such as Figure 1 to Figure 6 As shown, a cloth drying and winding equipment includes a base 1, a humidifying and drying device 2 and a material guiding and winding device 3. The humidifying and drying device 2 is arranged in the middle of the upper end of the base 1, and the material guiding and winding device 3 is arranged on the base. 1 the upper end; the guiding and winding device 3 guides, tightens and rewinds the cloth, and the humidifying and drying device 2 dries and irons the cloth.

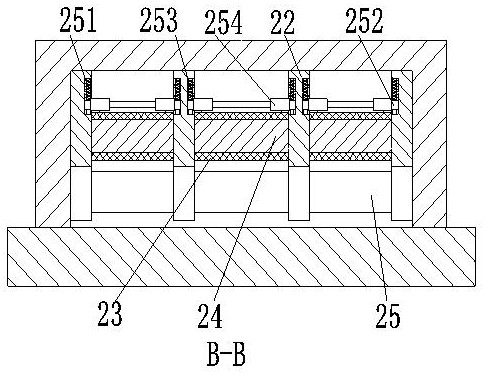

[0027] The humidifying and drying device 2 includes a drying frame 21, a rotating roller frame 22, a rotating roller 23, a drying ring 24, a cloth edge anti-warping mechanism 25, a direction-changing squeeze roller 26, a spray humidifier 27 and an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com