Double-hearth kiln top feeding device

A technology of a feeding device and a double-chamber kiln, which is applied in the field of lime production, can solve the problems of poor control of limestone distribution, lack of effective adjustment means, and harsh production environment on the top of the double-chamber kiln.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

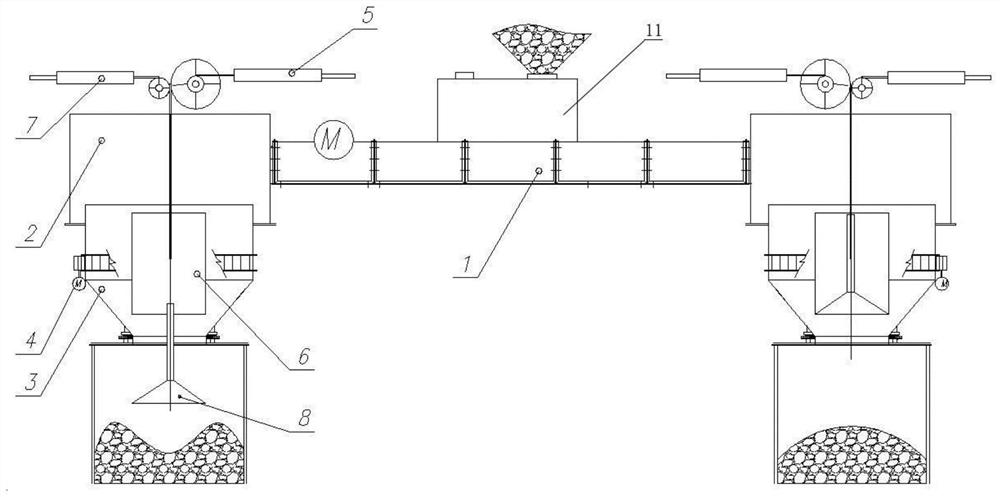

[0021] Such as figure 1 As shown, a double-chamber kiln top charging device includes a reversible belt conveyor, a rotating hopper, a liftable sleeve and a liftable material bell.

[0022] The reversible belt conveyor is an existing product, which is a belt conveyor, and the reversible belt conveyor is equipped with a reversible motor. The reversible belt conveyor is placed in the sealed housing 1, and the upper part of the sealed housing 1 is provided with a sealed feeding cover 11 and equipped with a dust removal pipe interface, so there is no dust during the feeding process. The reversible belt conveyor is equipped with a motor. By controlling the forward and reverse rotation of the motor, the two rotating hoppers can be fed separately.

[0023] The rotary hopper is composed of a fixed cover 2 and a hopper 3, and the fixed cover 2 is affixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com