Film tension detection device and operation method thereof

A technology of tension detection and thin film, which is applied in the direction of measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of poor stability, low efficiency, and high labor intensity, so as to improve the clamping effect and improve The effect of detection efficiency and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

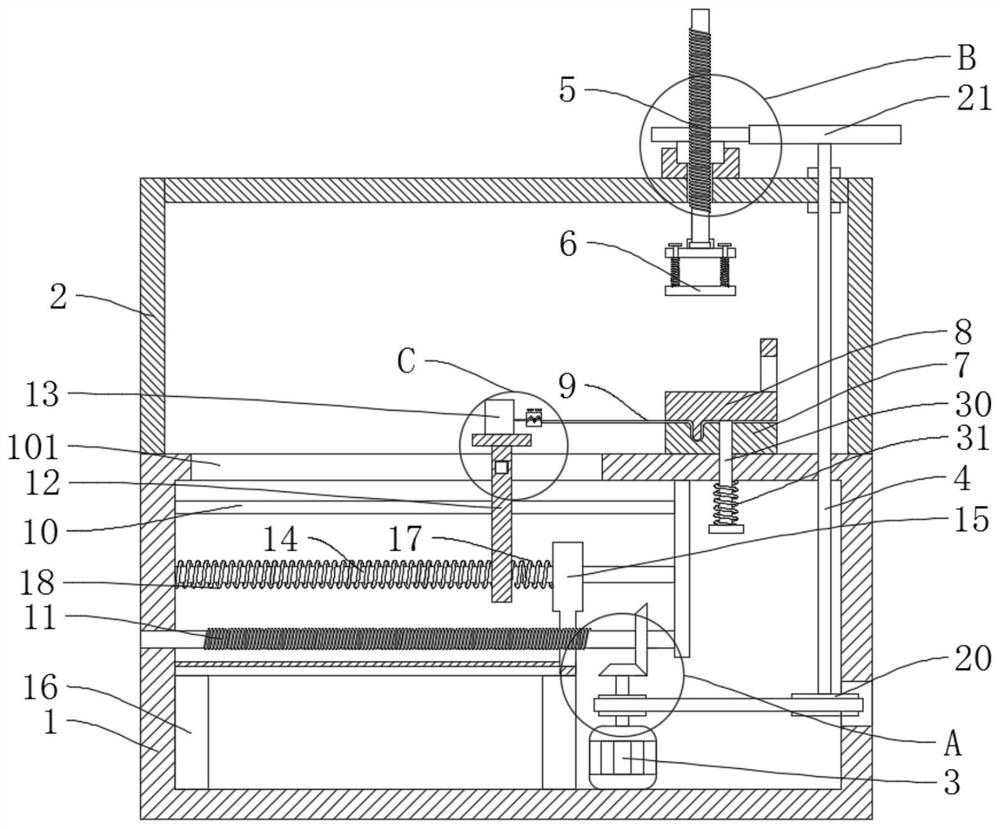

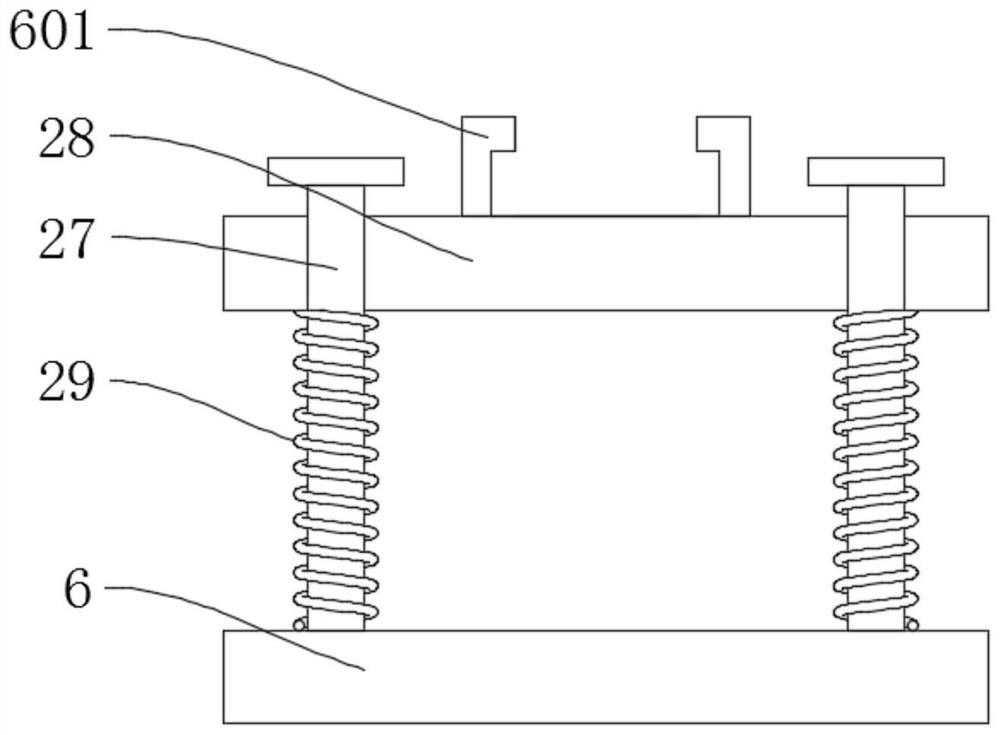

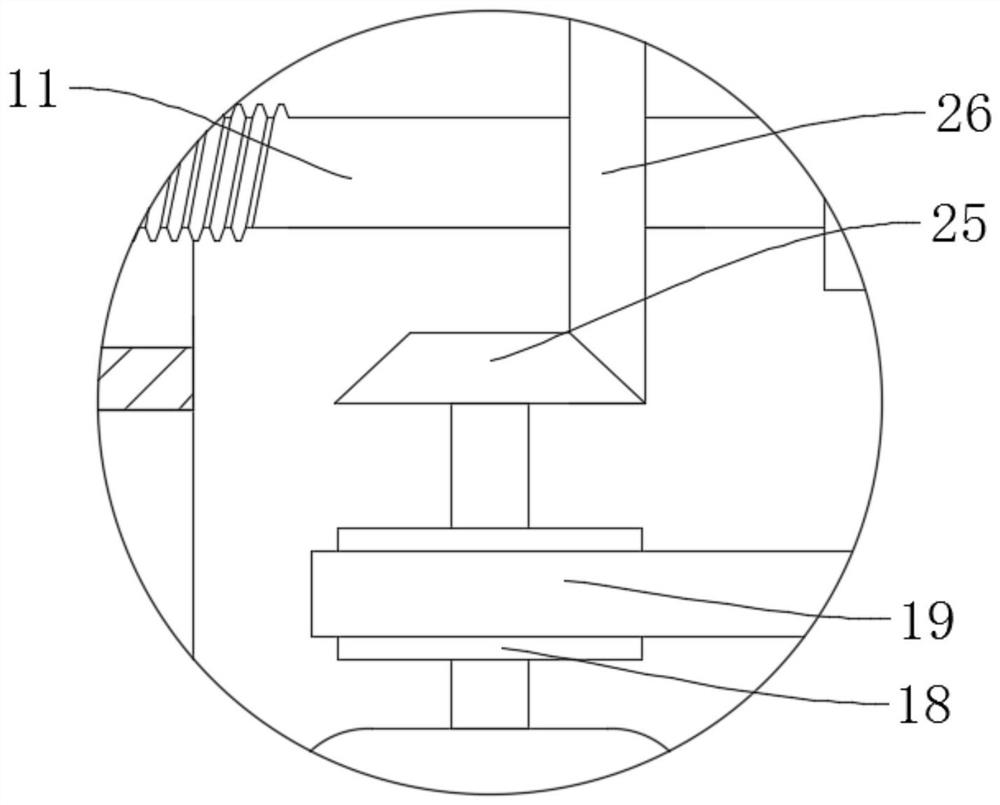

[0036] refer to figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7, a film tension detection device, comprising a base 1, a film to be detected 9 and a tension detector 13, a drive mechanism is fixedly connected to the base 1, a connecting rod 4 and a second threaded rod 11 are connected in rotation in the base 1, and the connecting rod 4 and the second threaded rod 11 are connected with the drive mechanism in rotation, the connecting rod 4 is connected with the first threaded rod 5 in rotation, the first threaded rod 5 is fixedly connected with the pressing plate 6, and the second threaded rod 11 is slidably connected with the slide plate 12. The slide plate 12 is fixedly connected with a support base 121, the tensile tester 13 is fixedly connected with the support base 121, the base 1 is fixedly connected with a workbench 7, the workbench 7 is provided with a clamping plate 8, and the detected film 9 is fixed Connected between the workbench 7 and the cl...

Embodiment 2

[0047] refer to figure 1 , figure 2 , Figure 5 , a film tension detection device, comprising a base 1, a film to be detected 9 and a tension detector 13, a drive mechanism is fixedly connected to the base 1, a connecting rod 4 and a second threaded rod 11 are connected in rotation in the base 1, and the connecting rod 4 and the second threaded rod 11 are connected with the drive mechanism in rotation, the connecting rod 4 is connected with the first threaded rod 5 in rotation, the first threaded rod 5 is fixedly connected with the pressing plate 6, and the second threaded rod 11 is slidably connected with the slide plate 12. The slide plate 12 is fixedly connected with a support base 121, the tensile tester 13 is fixedly connected with the support base 121, the base 1 is fixedly connected with a workbench 7, the workbench 7 is provided with a clamping plate 8, and the detected film 9 is fixed Connected between the workbench 7 and the clamping plate 8, the tensile tester 13...

Embodiment 3

[0058] An operation method of a film tension detection device adopts the following steps:

[0059] S1, pull the handle on the clamping plate 8, place the tested film 9 on the workbench 7, release the handle, and initially clamp the tested film 9 by the tension of the fourth spring 31 on the third slide bar 30, The U-shaped block 801 on the clamping plate 8 is engaged with the U-shaped groove 701 to further improve the clamping effect;

[0060] S2, the other end of the tested film 9 is fixed on the fixed block 131 on the tensile tester 13 to complete the fixation;

[0061] S3, start the motor 3, and the motor 3 drives the first threaded rod 5 to descend, and the pressing plate 6 is offset against the clamping plate 8 to further improve the clamping effect and prevent the detected film 9 from falling off during the detection process;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com