Automatic pecan sheller

A fruit shelling machine and pecan fruit technology, applied in the field of automatic pecan shelling machines, can solve the problems of cumbersome operation, high labor intensity, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

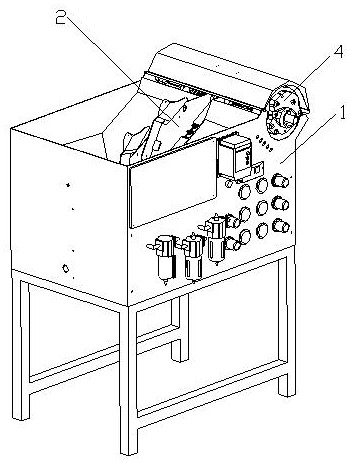

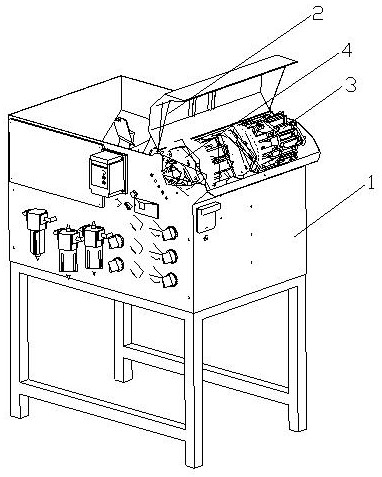

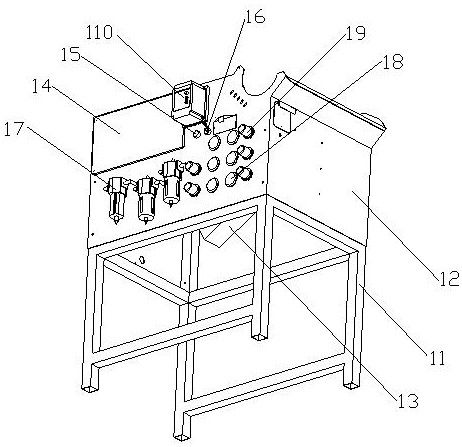

[0057] Such as Figure 1-Figure 27 As shown, the specific embodiment adopts the following technical solutions: it includes a base device 1, a feeding device 2, a positioning clamping device 3 and a shelling device 4, and a feeding device 2, a positioning clamping device 3 and a shelling device 4 According to a specific assembly relationship, it is fixedly installed on the base device 1, wherein the base device 1 is the base of the entire pecan sheller, and is used to install and fix other devices and parts, and position the clamping device 3 and the shelling device 4 Rotating at a certain speed along the main shaft, the feeding device 2 is mainly for queuing and arraying the pecans to be shelled, and through the feeding device 2, the pecans to be shelled fall to the positioning and clamping device 3 for positioning. The clamping device 3 positions and presses the pecans on the shelling device 4. With the rotation of the feeding device 2 and the positioning clamping device 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com