High-speed light splitting device for laser equipment

A technology of laser equipment and spectroscopic device, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inconvenient replacement of spectroscope, inconvenient replacement of heat dissipation device, inconvenient installation of spectroscope, etc., to achieve convenient Disassembly work, convenient sealing work, and the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

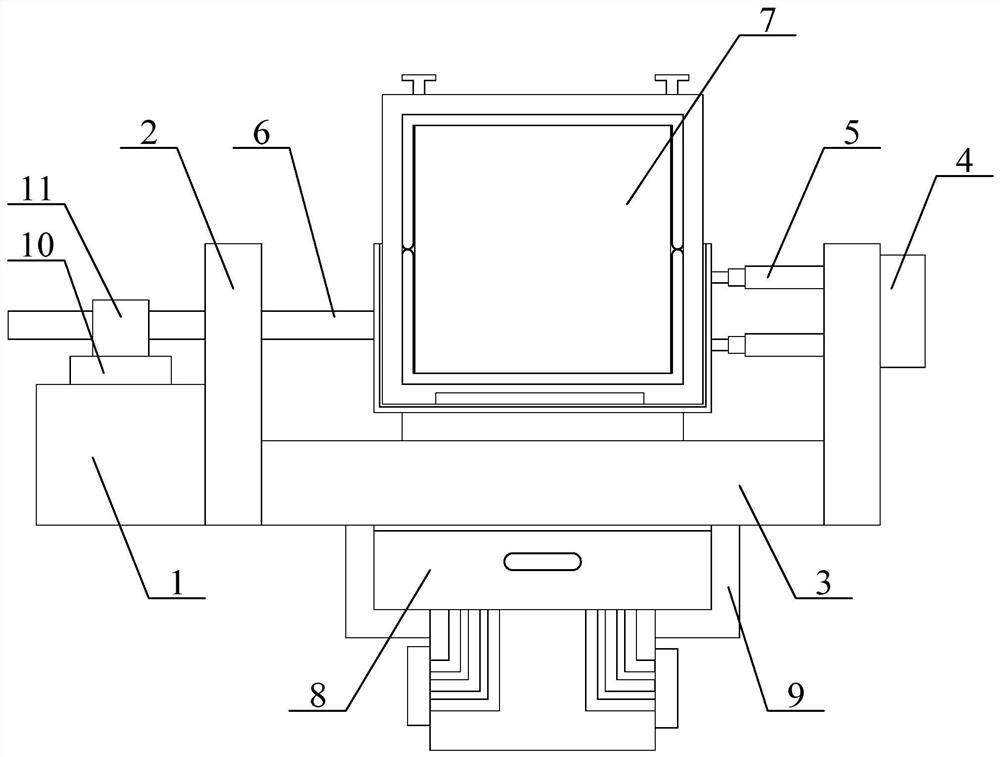

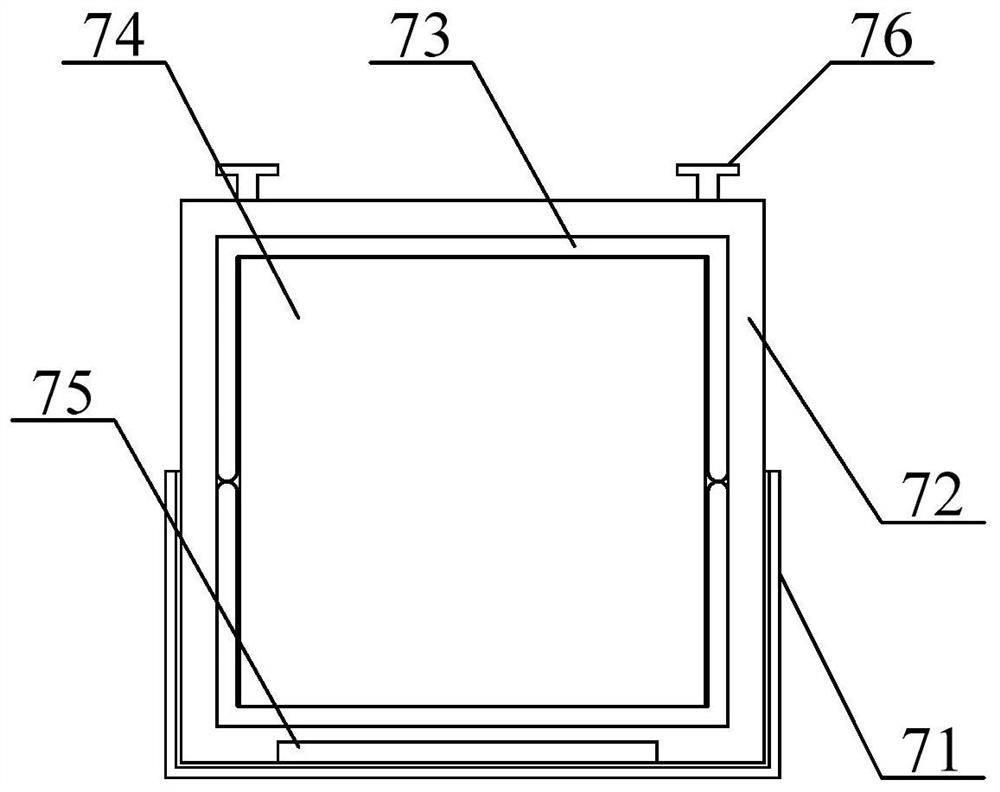

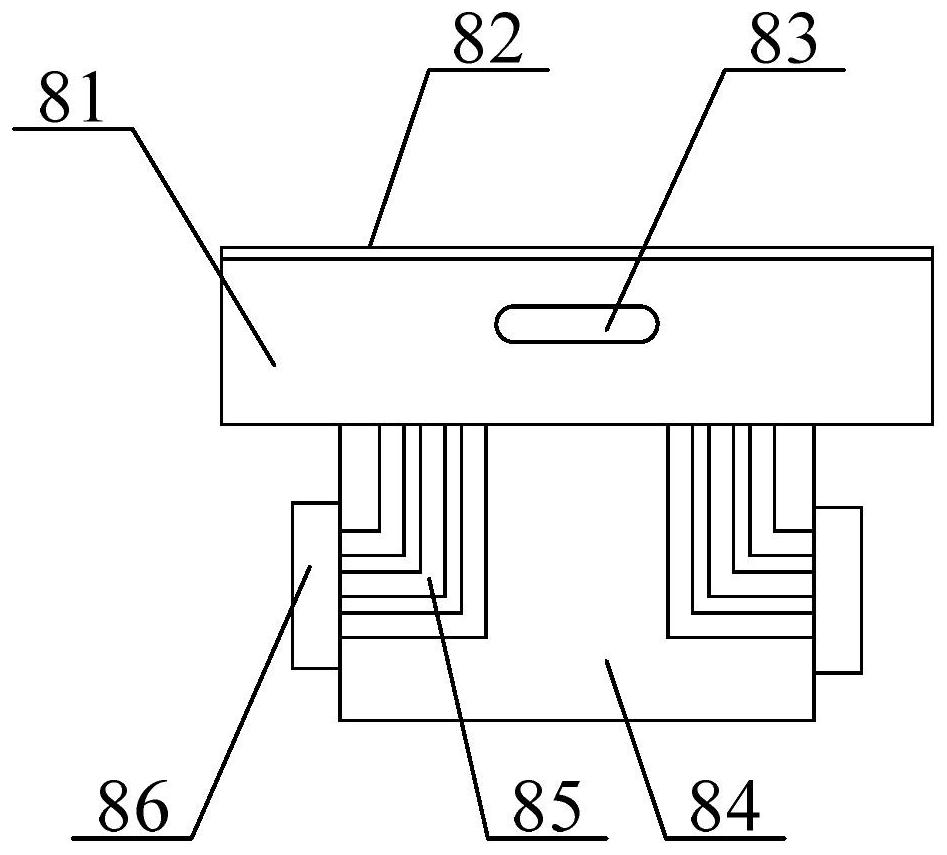

[0025] as attached figure 1 And attached figure 2 As shown, a high-speed spectroscopic device for laser equipment according to the present invention includes a mounting base 1, a column 2, a base 3, a driver 4, a telescopic rod 5, a threaded rod 6, a pluggable protective replacement frame structure 7, and a pluggable Connect the cooling box structure 8, the L-shaped fixed plate 9, the sliding seat 10 and the driving device 11, the mounting seat 1 is bolted to the left lower part of the column 2 and is arranged on the left side of the base 3; the base 3 The two ends are respectively bolted to the lower part between the columns 2; the driver 4 is bolted to the upper right side of the column 2 and arranged at the upper right corner of the base 3; The upper part of the left side is arranged on the right side of the upper end of the base 3; the threaded rod 6 runs through the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com