Composite material wing spar with high-precision curved surface and large length-diameter ratio and preparation method thereof

A composite material, large aspect ratio technology, applied in aircraft assembly, fuselage, weight reduction, etc., can solve the problem that the molding process cannot be applied to the wing spar, avoid secondary bonding and curing, reduce production costs, and improve connection. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

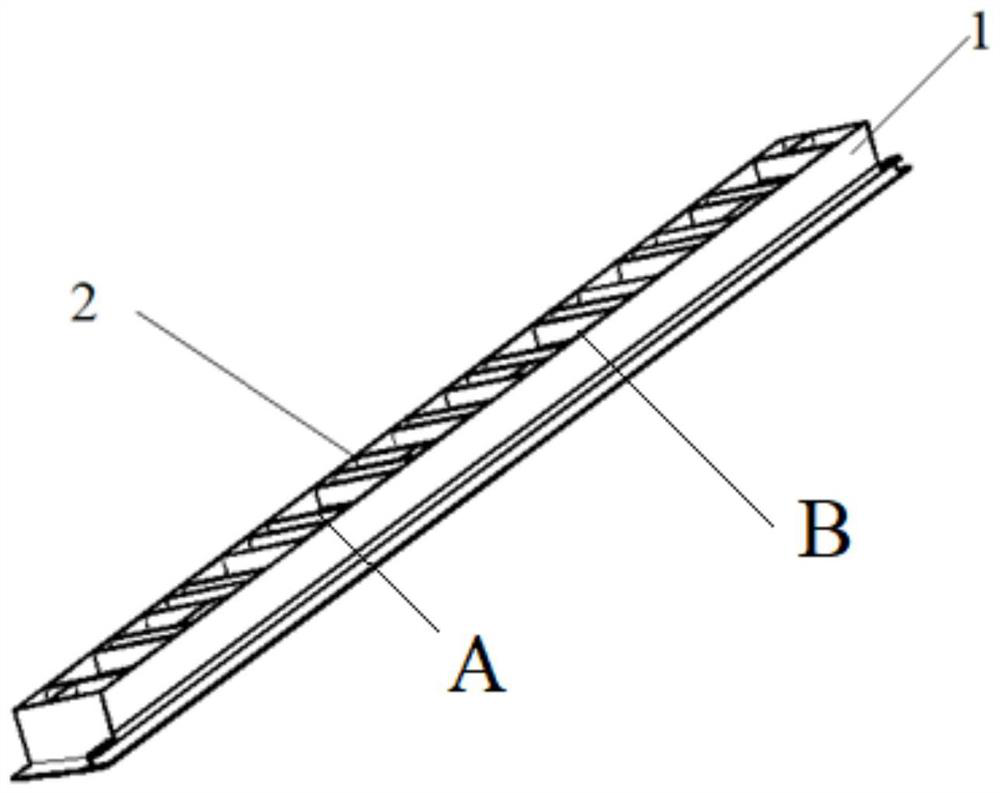

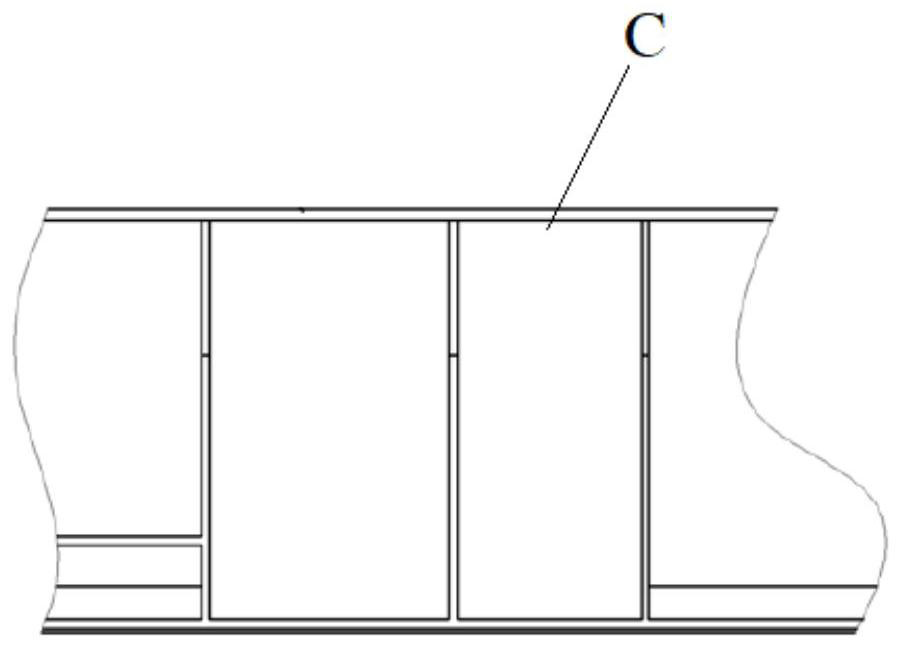

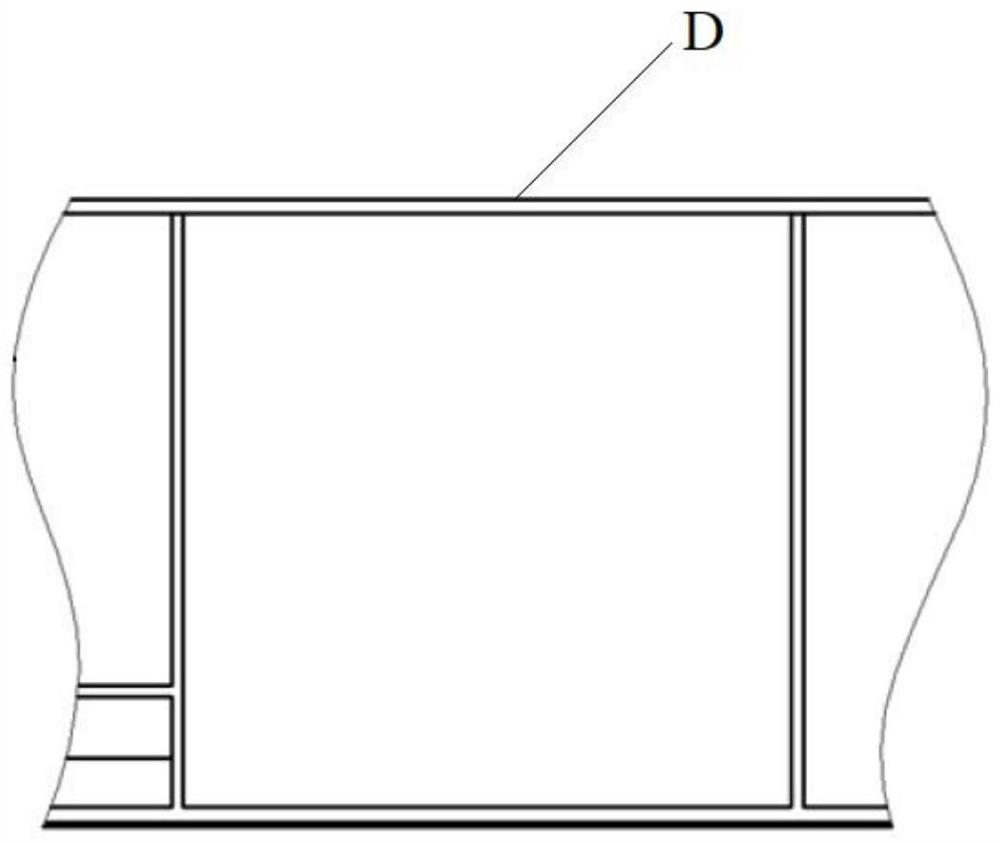

[0048] In this embodiment, the specific structure of the composite spar with high-precision curved surface and large aspect ratio can be referred to figure 1 to Figure 4 .

[0049] Such as figure 1 shown, and refer to the Figure 4 , in this embodiment, the composite material spar is an integral molding, wherein the composite material spar includes an integral beam box 1 and reinforcing ribs 2, the outer side of the lower end surface of the integral beam box 1 has a high-precision curved surface I, and the integral beam box 1 There is a guide groove 11 near the lower end surface of the box body side.

[0050] further combined figure 1 It can be seen that the overall beam box 1 is slender; the guide groove 11 is linear, the cross section of the guide groove 11 is "C" shaped, and the cross section of the structure formed by the guide groove 11 and the high-precision curved surface I is type.

[0051] Also, further reference figure 1 It can be seen that the reinforcing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com