Ground grooving equipment for road engineering and construction method thereof

A technology of road engineering and slotting equipment, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of health threats to workers, unfavorable ground slotting construction, unfavorable pipeline construction, etc., to reduce the spread of dust and reduce Destroying and benefiting the effect of pipeline construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

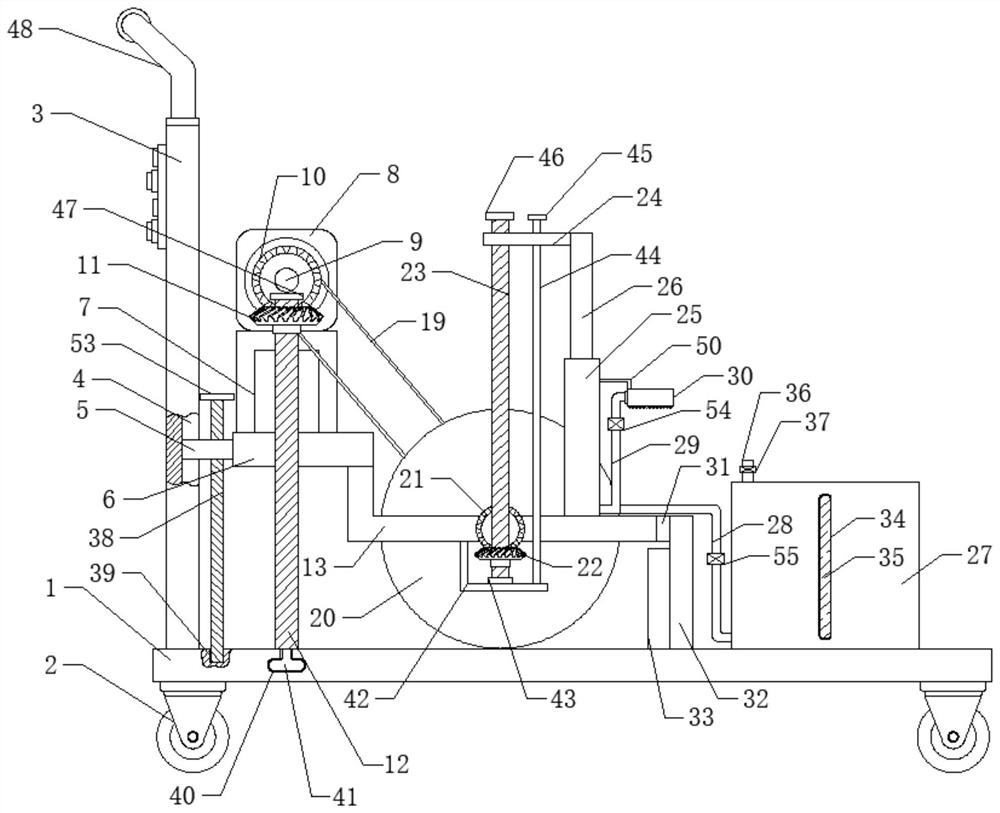

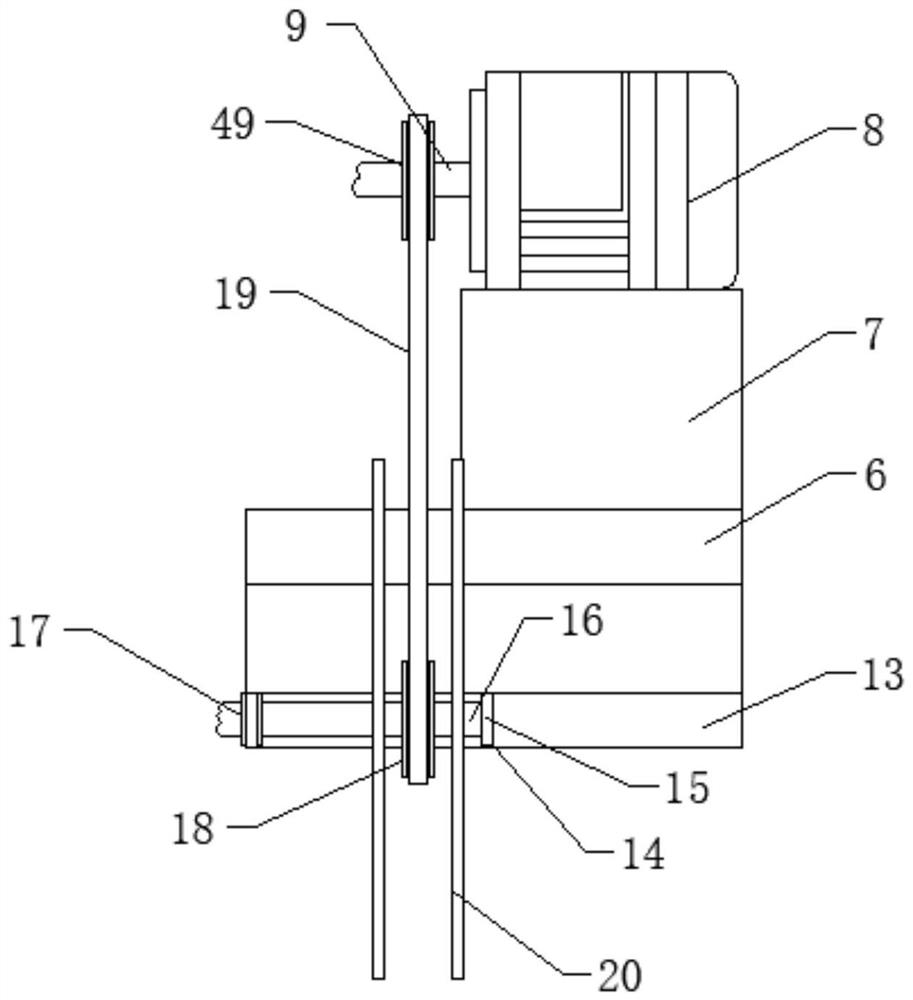

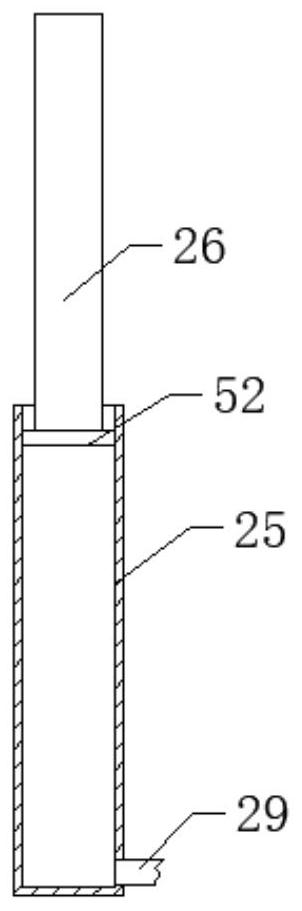

[0028] see Figure 1-5, the present invention provides a technical solution: a ground slotting equipment for road engineering, comprising a first plate body 1, a second plate body 3 is welded on the upper surface of the first plate body 1, and one side of the second plate body 3 A first limit chute 4 is provided, the inner side wall of the first limit chute 4 is slidably connected with a first limit slider 5, one side of the first limit slider 5 is welded with a first fixed plate 6, and the first limit slider 5 is welded with a first fixed plate 6. The upper surface of a fixed plate 6 is fixedly connected with a second fixed plate 7, the upper surface of the second fixed plate 7 is equipped with a motor 8, the output end of the motor 8 is fixedly connected with a first rotating shaft 9, and the outer wall of the first rotating shaft 9 is fixed The first bevel gear 10 is connected, the outer wall of the first bevel gear 10 is engaged with the second bevel gear 11, the inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com