Extruded sheet surface treatment equipment

A technology of surface treatment and extruded board, applied in metal processing and other directions, can solve the problems of inability to adjust the size and thickness of extruded board, poor contact effect between extruded board and mortar, poor processing effect, etc., which is conducive to long-term use. , good adjustment effect, good grooving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

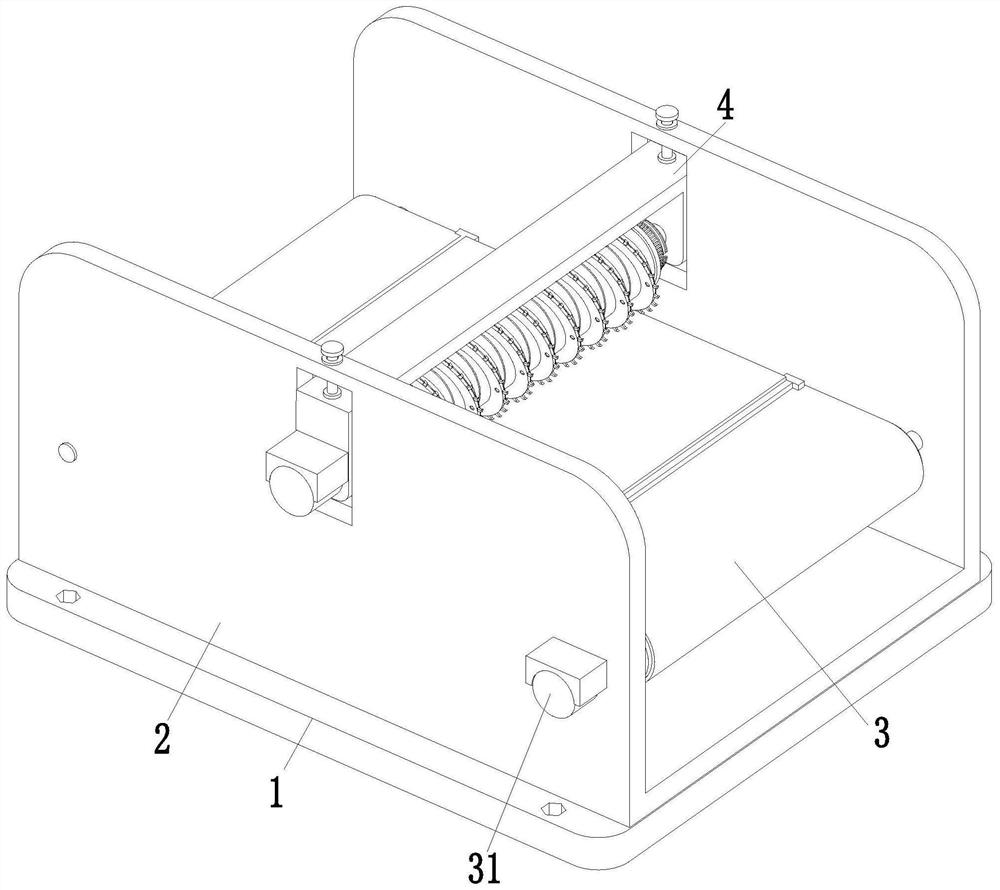

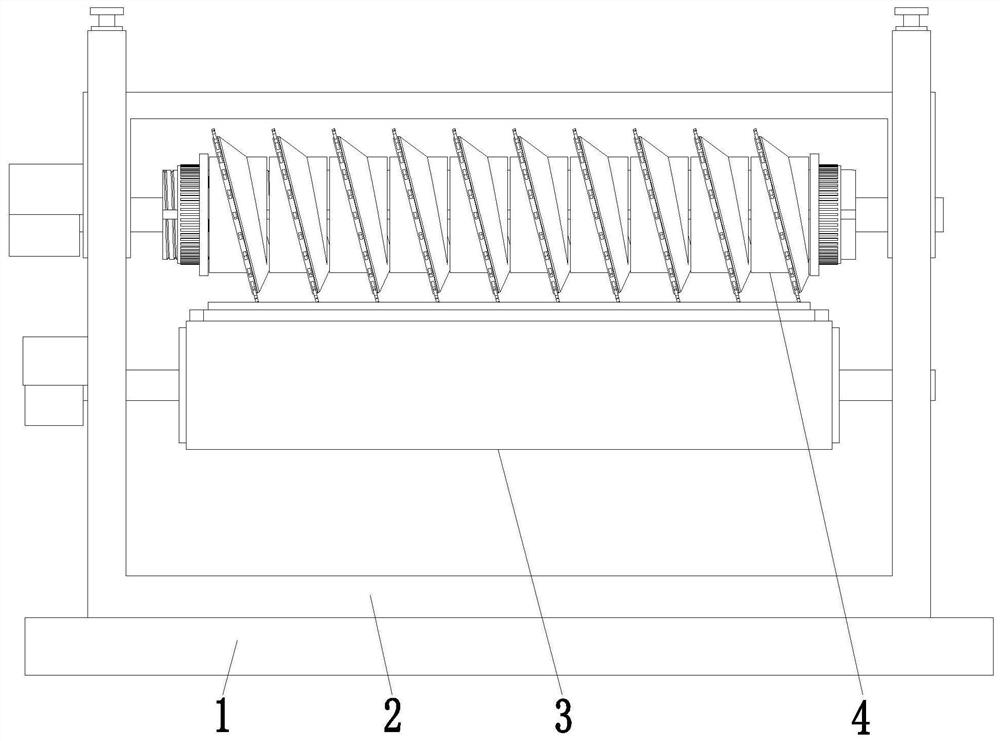

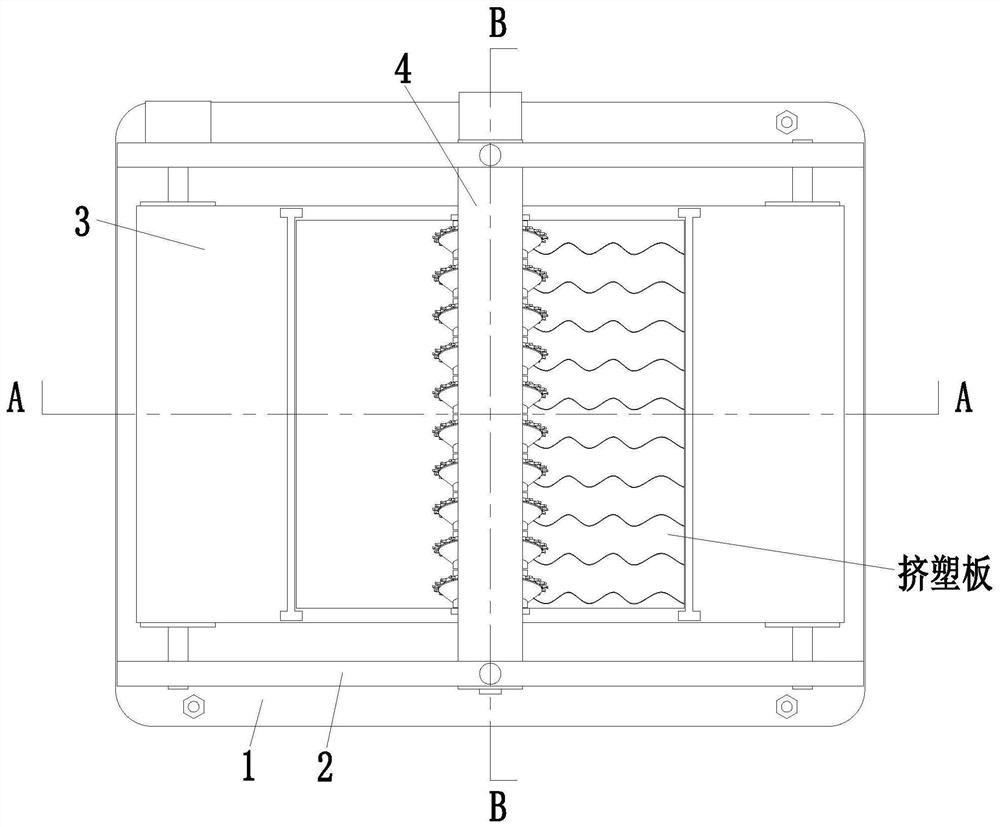

[0036] like Figure 1 to Figure 11 As shown, an extruded board surface treatment equipment includes a bottom plate 1, a fixed frame 2, a conveying unit 3 and a processing unit 4. The upper end of the bottom plate 1 is equipped with a fixed frame 2, and the section of the fixed frame 2 is a U-shaped structure. A conveying unit 3 is installed at the lower end inside the frame 2 , and a processing unit 4 is arranged above the conveying unit 3 , and the processing unit 4 is installed on the fixed frame 2 .

[0037] The conveying unit 3 includes a driving motor 31, a conveying roller 32, a conveying belt 33, a material blocking plate 34 and a guide roller 35. The conveying roller 32 is symmetrically installed in the inside of the fixed frame 2 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com